Biomass fuel aluminum melting furnace

A biomass fuel, aluminum melting furnace technology, applied in furnaces, crucible furnaces, furnace types, etc., can solve the problems of low heat exchange efficiency between flame and crucible, increase the production cost of molten aluminum, and large temperature fluctuations of the crucible, and achieve stable use. Good performance, saving fuel cost and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

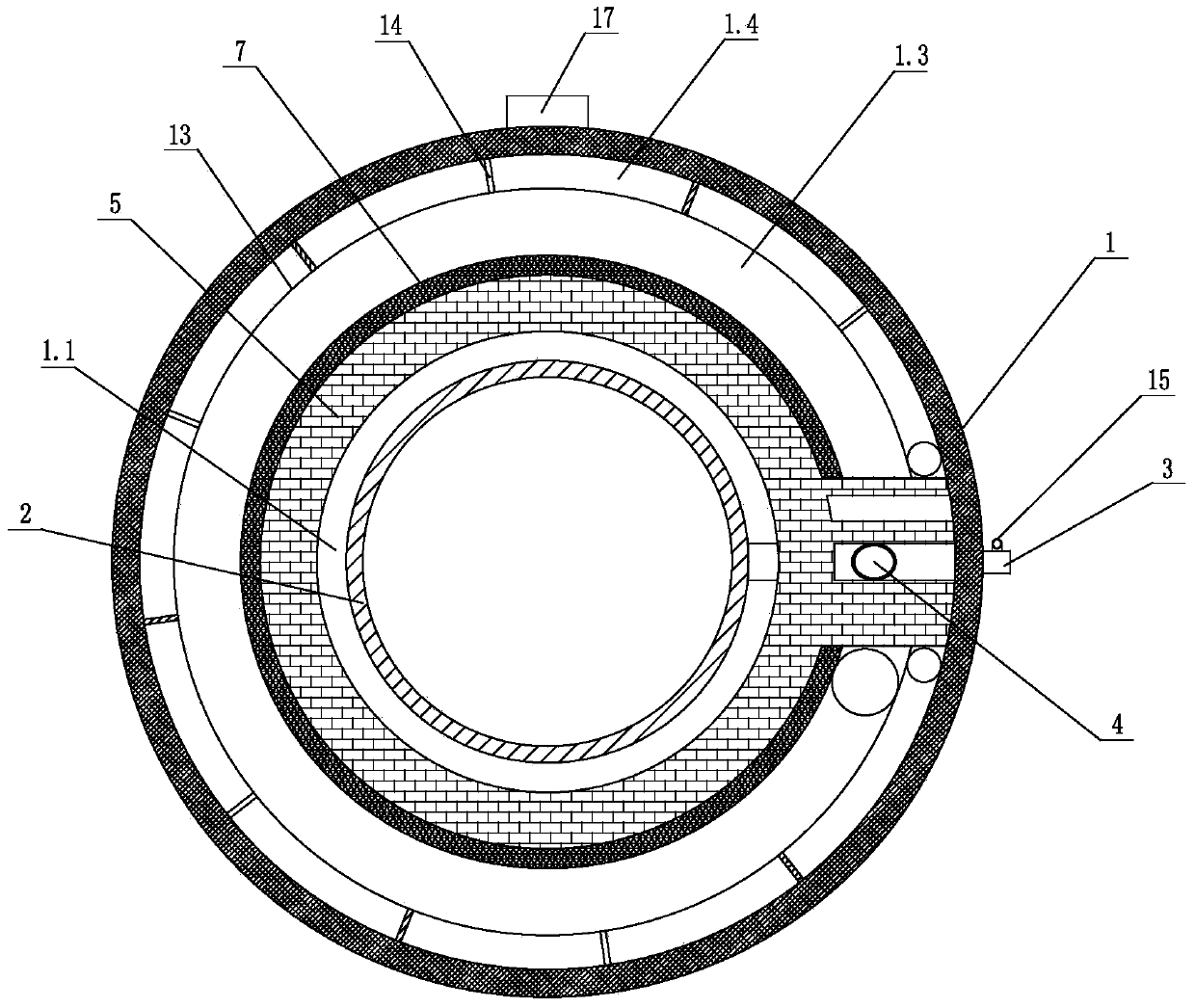

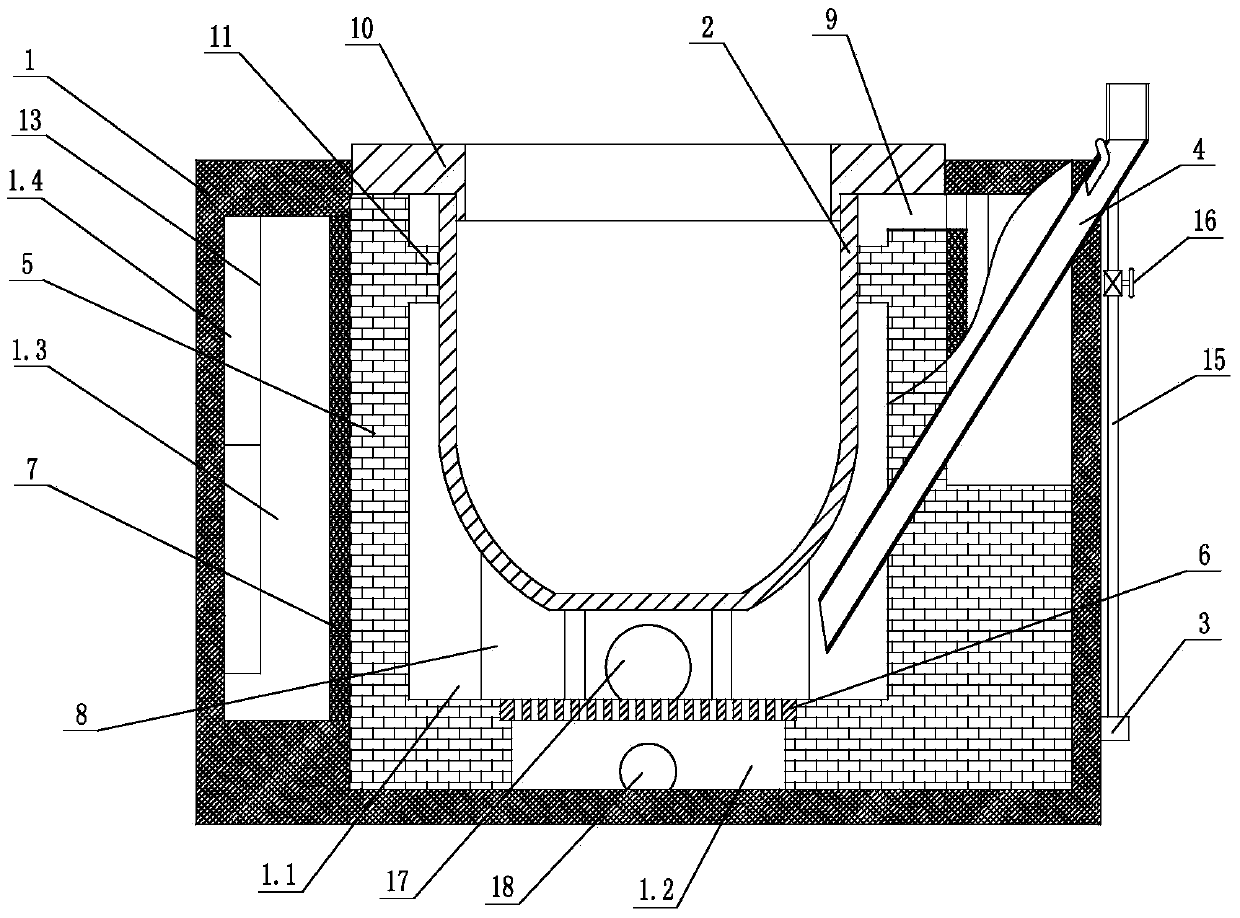

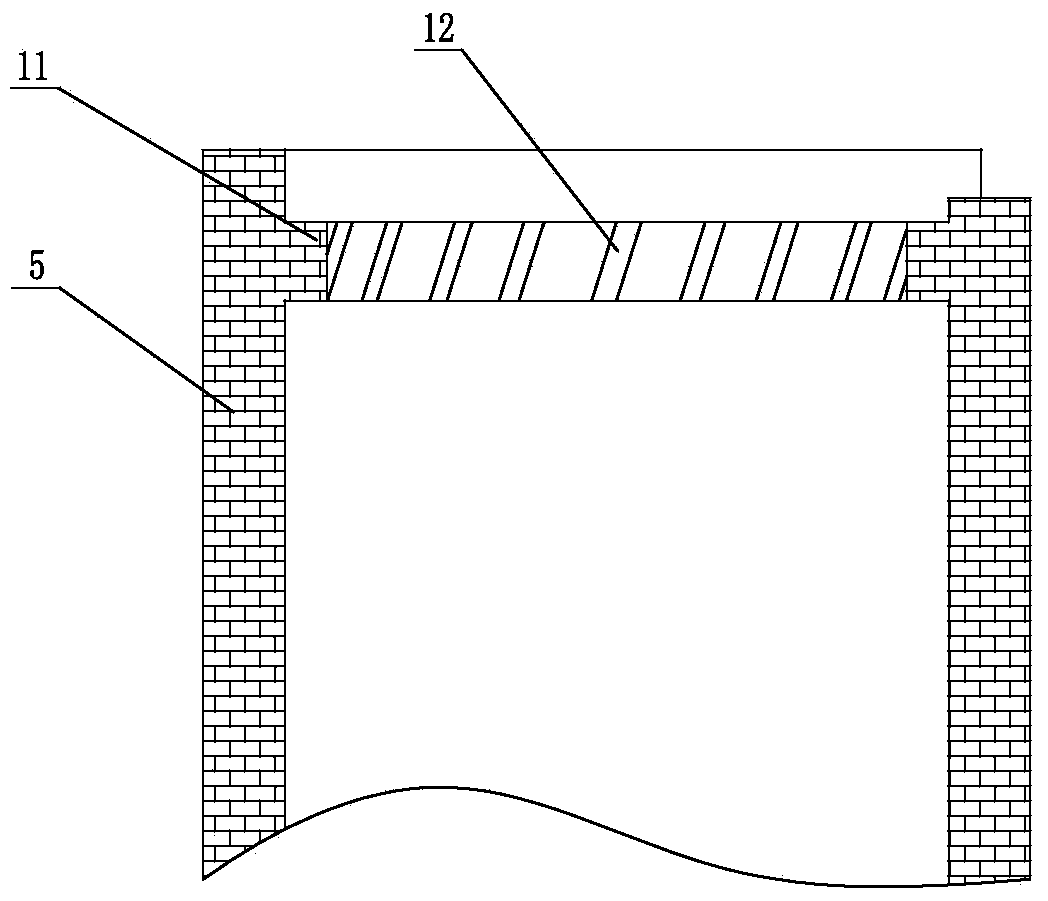

[0020] Such as figure 1 , figure 2 and image 3 Shown, a kind of biomass fuel melting aluminum furnace, it comprises furnace body 1, crucible 2, air inlet 3 and feed pipe 4 (certainly also comprises other parts, but because do not relate to the invention point that the present invention creates, so in This will not be repeated), the furnace body 1 is provided with a cavity separated by the refractory brick layer 5, and the combustion chamber 1.1 and the ash chamber 1.2 are arranged in the cavity, and the combustion chamber 1.1 passes through the grate 6 It communicates with the furnace ash chamber 1.2, the air inlet 3 is located at the lower end of the furnace body 1, the crucible 2 is located in the combustion chamber 1.1, and the outer periphery of the refractory brick layer 5 corresponding to the combustion chamber 1.1 is covered with hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com