Waterborne intermediate paint coating and preparation method thereof

An intermediate paint, water-based technology, applied in the field of coatings, can solve the problems of easy sagging, flame retardancy, poor thick coating effect, poor anti-corrosion effect, etc., and achieve the effect of good wetting ability, low equipment requirements and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

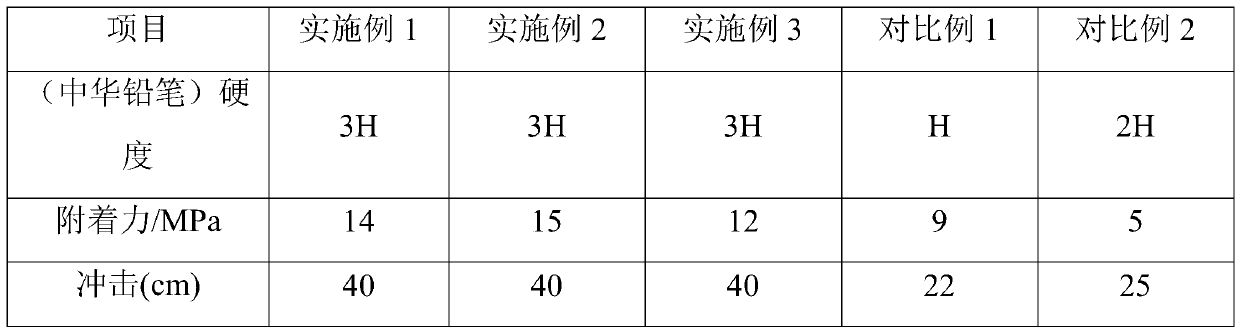

Examples

Embodiment 1

[0032] A water-based intermediate paint, comprising A component and B component;

[0033] Described A component comprises the component of following mass percentage:

[0034] raw material Mass ratio (%) epoxy emulsion 30 Dispersant 0.1 Defoamer 0.1 Coalescent 1 Mica Iron Oxide 40 glass flakes 10 filler 10 Barium sulfate 2 pigment 0 expanded graphite 0.2 Vermiculite 0.2 fumed silica 0.2 Anti-flash rust agent 0.1 Zirconium phosphate 0.1 Substrate wetting agent 0.3 thickener 0.5 Deionized water 5.2

[0035] Described B component comprises the component of following mass percentage:

[0036] raw material Mass ratio (%) Hardener 80 Coalescent 20

[0037] The mass ratio of the A component and the B component is 4:1.

[0038] Among them, the epoxy emulsion is GE80 from Shanghai Aishibo Organic Silicon Material Co., Ltd.; the dispersant is A...

Embodiment 2

[0044] A water-based intermediate paint, comprising A component and B component;

[0045] Described A component comprises the component of following mass percentage:

[0046] raw material Mass ratio (%) epoxy emulsion 45 Dispersant 0.3 Defoamer 0.3 Coalescent 3 Mica Iron Oxide 20 glass flakes 5 filler 5 Barium sulfate 5 pigment 5 expanded graphite 2 Vermiculite 2 fumed silica 0.5 Anti-flash rust agent 0.3 Zirconium phosphate 0.5 Substrate wetting agent 0.4 thickener 0.8 Deionized water 4.9

[0047] Described B component comprises the component of following mass percentage:

[0048] raw material Mass ratio (%) Hardener 85 Coalescent 15

[0049] The mass proportion of the A component and the B component is 6:1.

[0050] Among them, the epoxy emulsion is GE80 from Shanghai Aishibo Organic Silicon Material Co., Ltd.; the dispersant is AF...

Embodiment 3

[0056] A water-based intermediate paint, comprising A component and B component;

[0057] Described A component comprises the component of following mass percentage:

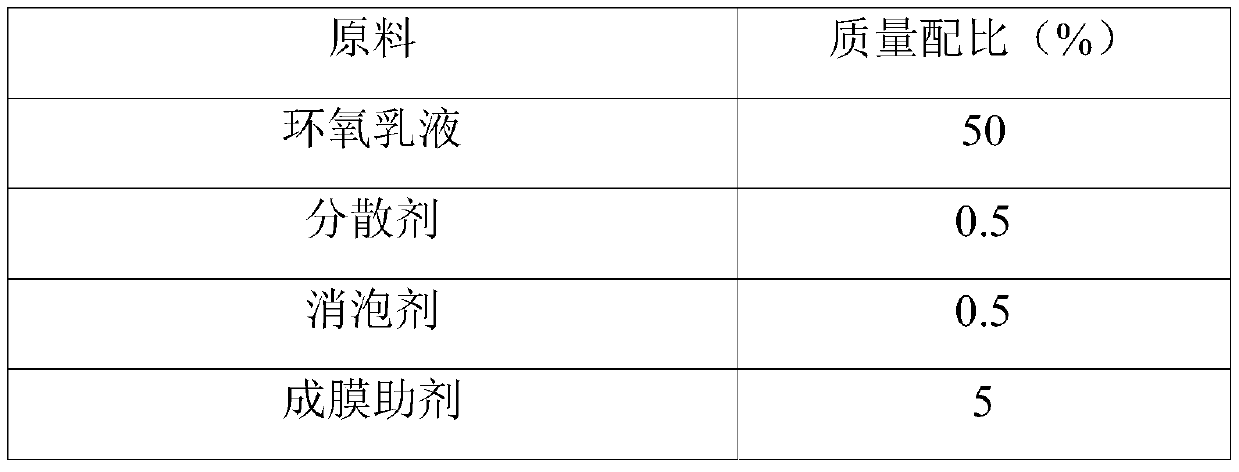

[0058]

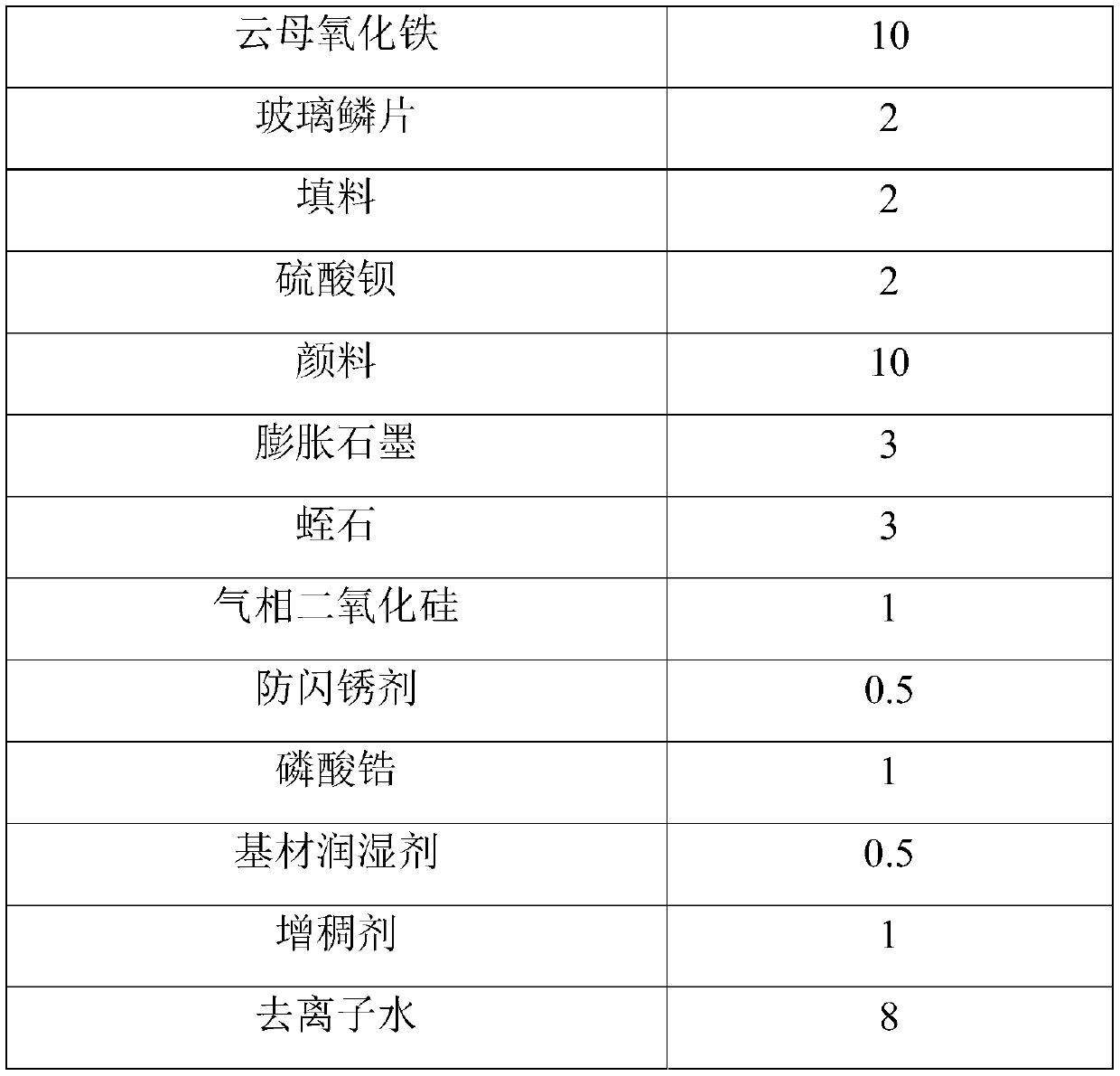

[0059]

[0060] Described B component comprises the component of following mass percentage:

[0061] raw material Mass ratio (%) Hardener 80 Coalescent 20

[0062] The mass proportion of the A component and the B component is 8:1.

[0063] Among them, the epoxy emulsion is GE80 from Shanghai Aishibo Organic Silicon Material Co., Ltd.; the dispersant is AFCONA-5010 from Efcona; the defoamer is BYK-028 from BAK; the film-forming aid is propylene glycol methyl ether; The particle size of micaceous iron oxide is 1000 mesh; Glass flakes select the 450 mesh glass flakes of Tianjin Rengang Chemical Co., Ltd.; Described filler is 1500 mesh mica powder; Described barium sulfate is 1600 mesh; Described pigment is carbon black, selects The MA100 of Japan's Mitsubishi Corporation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com