Scraper evaporator

An evaporator and scraper technology, which is applied in the field of concentration and solvent recovery devices, can solve the problems of large resistance of the rotating scraper, poor concentration effect, shaking of the scraper shaft, etc., to achieve reduced shaking, good concentration effect, and improved use safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

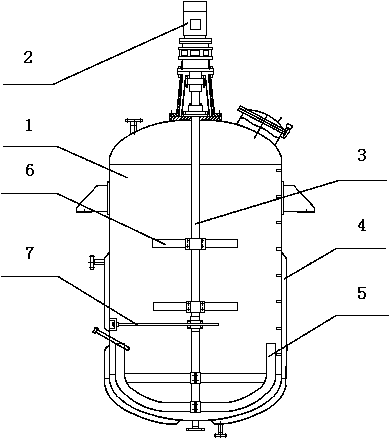

[0010] As an embodiment of the present invention, such as figure 1 As shown, a scraper evaporator includes a hollow tank body 1, a motor 2 is arranged at the top of the tank body 1, a rotating shaft 3 is arranged vertically inside the tank body 1, and the output end of the motor 2 is connected to the rotating shaft 3 The end of the rotating shaft 3 away from the motor 2 is provided with a scraper 5. In this embodiment, preferably, the scraper 5 is U-shaped, which increases the contact area between the scraper 5 and the solution. A jacket 4 is arranged outside the tank body 1, and several reinforcing ribs are arranged on the inner wall surface of the tank body 1, which improves the strength and rigidity of the tank body 1, makes the tank body 1 not easy to be damaged, and prolongs the service life of the tank body 1. A number of stirring paddles 6 are arranged on the shaft 3 between the motor 2 and the scraper 5, and the stirring paddles 6 are arranged at intervals in parallel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com