Modified vinyl silicon resin and preparation method thereof, and paint composition containing resin and preparation method thereof

A vinyl silicone resin, modified technology, applied in the direction of coating, etc., can solve the problems of high VOC content and low VOC content, and achieve the effects of enhanced reprocessing performance, VOC reduction, and enhanced rheological properties of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

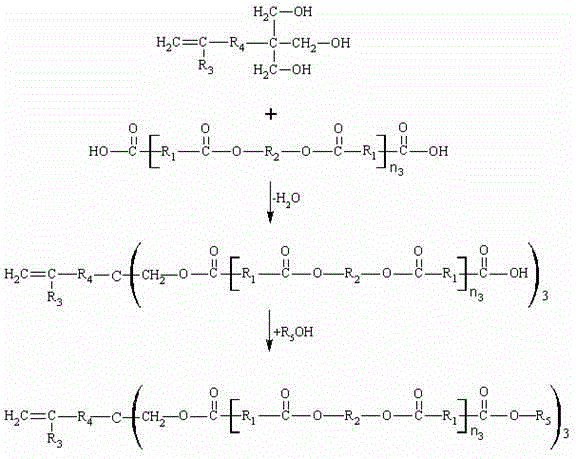

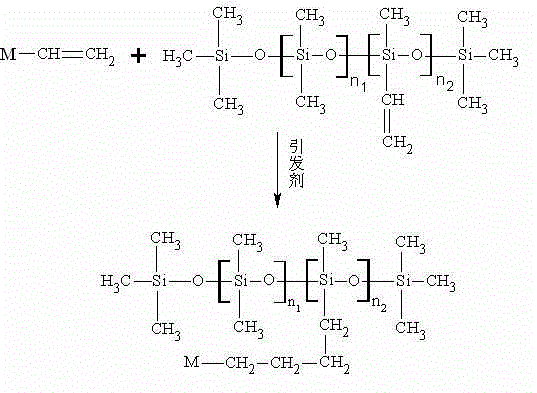

[0024] The present invention also provides a method for preparing the modified vinyl silicone resin of the present invention. The method includes the following steps:

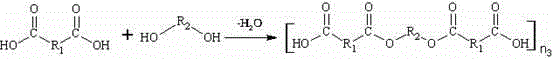

[0025] S1. Synthesize a carboxyl-terminated saturated polyester. In a reaction vessel equipped with a water separator, a reflux condenser, a stirrer and a thermometer, mix the polyacid, polyol, catalyst and the first solvent to form a mixture. ℃ Heat the mixture to 150-170℃, when the mixture is completely melted, start stirring, keep it for 0.5-1.5h, the water separator will start to remove water from then on, and the temperature will be uniformly increased to 210-230℃ within 2.5-3.5h, the heating rate The temperature is 10-40°C / h, the temperature is kept for 0.5-1.5h, and the water is kept removed; the molar ratio of the carboxyl group and the hydroxyl group is 1.05-1.1:1; the specific equation is as follows:

[0026]

[0027] S2. Synthesize the alkyl-terminated hyperbranched alkenyl polyester, cool the carboxyl-te...

Embodiment 1

[0063] (1) Synthesis of modified silicone resin:

[0064] Add 166KG isophthalic acid, 146KG adipic acid, 200KG neopentyl glycol, 4KG dibutyltin dilaurate and 60KG xylene into a reaction vessel equipped with a water trap, reflux condenser, stirrer and thermometer. Heat to 160°C within 30 minutes, start stirring after all the materials are melted, the reaction begins to produce water, keep it warm for 1 hour, and the water separator starts to remove water from then on. Raise the temperature from 160°C to 220°C at a constant rate within 3h, with a heating rate of 20°C / h, keep the temperature for 1h, and keep water removal. Then the temperature was lowered to 180°C, 40kg of olefin-based polyhydroxy monomer and 20kg of xylene were added, and the temperature was increased to 220°C at a constant rate for 2h, and the temperature was kept for 1h. Cool down to 180℃, add 20KG n-butanol and 20KG xylene, then use 2h to increase the temperature evenly to 220℃, continue to keep warm, test the ...

Embodiment 2

[0072] (1) Synthesis of modified silicone resin:

[0073] Add 166KG isophthalic acid, 146KG adipic acid, 189KG neopentyl glycol, 4KG dibutyltin dilaurate and 60KG xylene in a reaction vessel equipped with a water trap, reflux condenser, stirrer and thermometer. Heat to 160°C within 30 minutes, start stirring after all the materials are melted, the reaction begins to produce water, keep it warm for 1 hour, and the water separator starts to remove water from then on. Raise the temperature from 160°C to 220°C at a constant rate within 3h, with a heating rate of 20°C / h, keep the temperature for 1h, and keep water removal. Then the temperature was lowered to 180°C, 40kg of olefin-based polyhydroxy monomer and 20kg of xylene were added, and the temperature was increased to 220°C at a constant rate for 2h, and the temperature was kept for 1h. Cool down to 180℃, add 20KG n-butanol and 20KG xylene, then use 2h to increase the temperature evenly to 220℃, continue to keep warm, test the ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com