High-content graphene modified nylon 6 master batch as well as preparation method and application thereof

A graphene modification and high-content technology, which is applied in the manufacture of conductive/antistatic filaments, conjugated synthetic polymer artificial filaments, etc., can solve the problems of graphene dispersion and achieve increased viscosity and high dispersion , the effect of accelerating the dispersion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

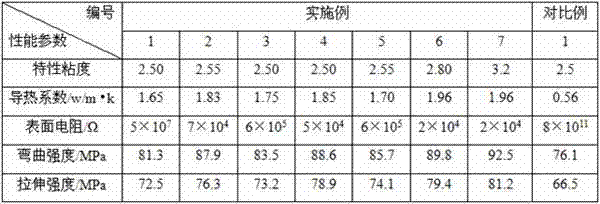

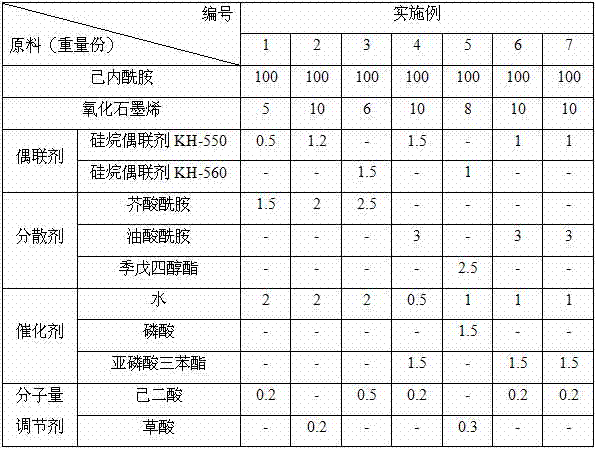

[0047] Table 1 Raw material composition of high-content graphene-modified nylon 6 masterbatches in Examples 1-7

[0048]

[0049] Note: "-" in the table means not added.

[0050] Examples 1-5 of the preparation method of high-content graphene-modified nylon 6 masterbatch

[0051] (1) According to the weight parts of the raw materials in Examples 1 to 5 in Table 1, add graphene oxide and coupling agent to a high-speed stirrer and mix them. At 80°C, with a stirring speed of 60r / min and an ultrasonic frequency of 35Hz, heat and ultrasonically stir for 15min , then add a dispersant, heat and stir at 80°C and a stirring speed of 220r / min for 8min, then add a catalyst, heat and stir at 65°C and a stirring speed of 70r / min for 6min to obtain a graphene slurry;

[0052] (2) Add caprolactam and molecular weight regulator into the polymerization kettle according to the weight parts of each raw material in Example 1 to 5 in Table 1, heat to 80°C until the caprolactam melts, and add t...

Embodiment 7

[0059] (1) According to the weight parts of each raw material in Example 7 of Table 1, add graphene oxide and coupling agent into a high-speed stirrer and mix them. At 80°C, with a stirring speed of 60r / min and an ultrasonic frequency of 30Hz, heat and ultrasonically stir for 15min, and then Add a dispersant, heat and stir at 90°C and a stirring speed of 240r / min for 10min, then add a catalyst, heat and stir at 70°C and a stirring speed of 80r / min for 7min to obtain a graphene slurry;

[0060](2) Add the caprolactam and the molecular weight regulator into the polymerization kettle according to the weight parts of the raw materials in Example 7 of Table 1, heat to 90°C until the caprolactam melts, and add the graphene slurry obtained in step (1) at a stirring speed of 120r / min After the feeding of the graphene slurry is completed, continue to heat up to 270°C, and carry out the ring-opening reaction at a stirring speed of 90r / min for 3.5h, then start vacuuming to a vacuum degree...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com