Fracturing technology using propping agent density variation for obtaining large channels

A technology of density difference and proppant, which is applied in the direction of drilling composition, production fluid, wellbore/well components, etc., can solve the problems affecting the effect of fracturing, high closure pressure, limited support capacity, etc., and achieve improved stability properties, increase viscosity, and reduce sedimentation velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

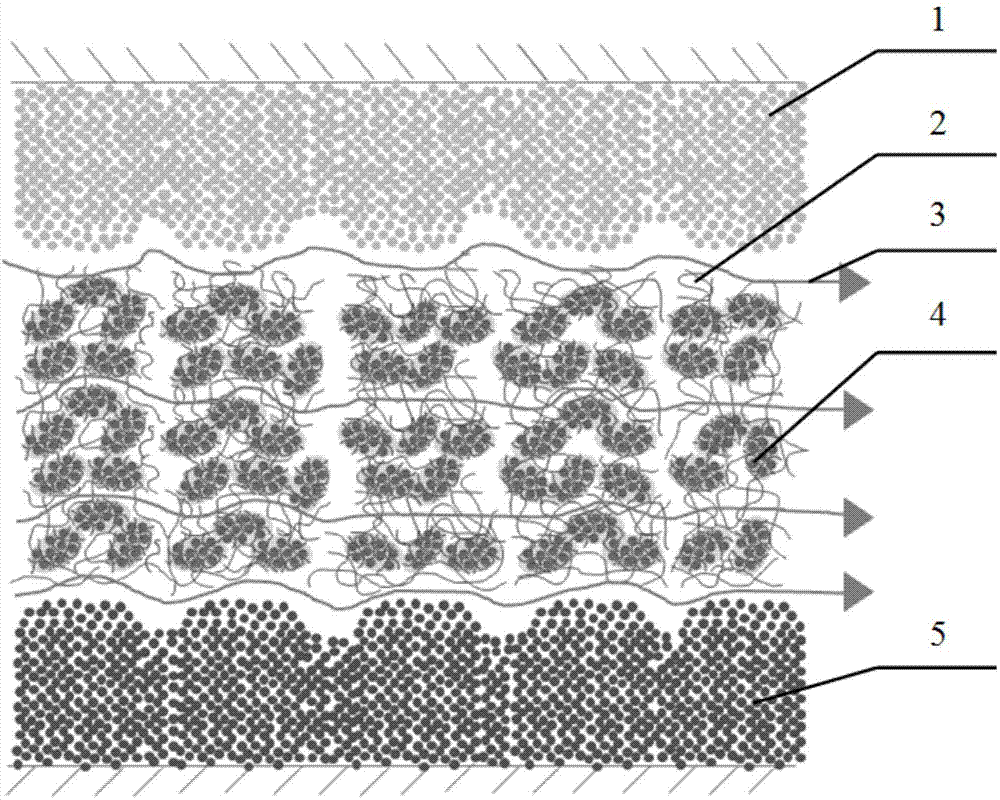

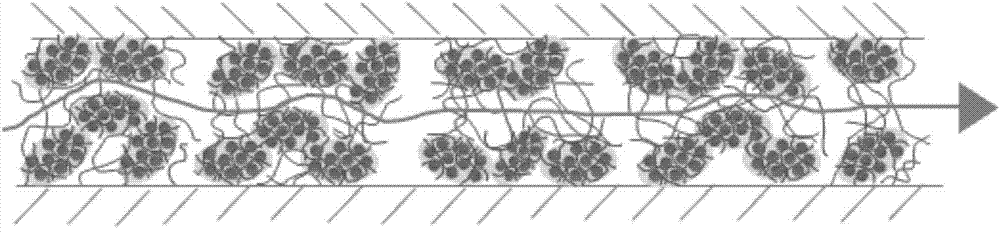

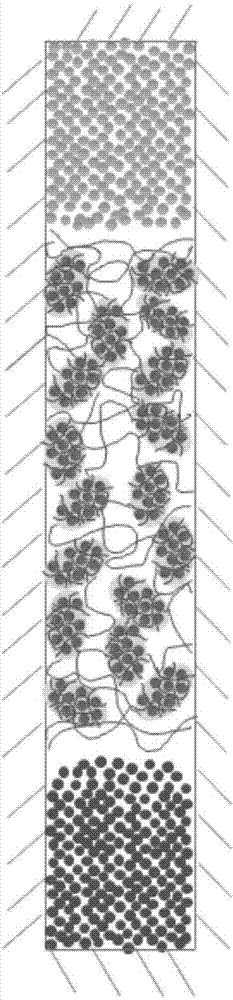

[0045] A fracturing process for realizing large channels by using difference in proppant density, comprising the following steps:

[0046] (1) Mix the low-density proppant and the high-density proppant with the fracturing fluid base fluid respectively to obtain the low-density proppant fracturing fluid and the high-density proppant fracturing fluid, and the low-density proppant fracturing fluid The sand ratio of the proppant and high-density proppant fracturing fluid is 15%, and the density of the low-density proppant is 1g / cm 3 , hollow particles; the density of the high-density proppant is 2.5g / cm 3 ;

[0047] (2) Mix medium-density proppant, fiber and fracturing fluid base fluid evenly to obtain fiber-containing medium-density proppant fracturing fluid; the sand ratio of the medium-density proppant fracturing fluid is 12%, and the The medium density proppant has a density of 1.2g / cm 3 , the quality of fiber added in every cubic meter of proppant is 2kg;

[0048] (3) At ...

Embodiment 2

[0053] A fracturing process for realizing large channels by using difference in proppant density, comprising the following steps:

[0054] (1) Mix the low-density proppant and the high-density proppant with the fracturing fluid base fluid respectively to obtain the low-density proppant fracturing fluid and the high-density proppant fracturing fluid, and the low-density proppant fracturing fluid The sand ratio of the proppant and high-density proppant fracturing fluid is 15%, and the density of the low-density proppant is 1.1g / cm 3 , hollow particles; the density of the high-density proppant is 3.0g / cm 3 ;

[0055] (2) Mix medium-density proppant, fiber and fracturing fluid base fluid evenly to obtain fiber-containing medium-density proppant fracturing fluid; the sand ratio of the medium-density proppant fracturing fluid is 12%, and the The medium density proppant has a density of 1.5g / cm 3 , the mass of fibers added to each cubic meter of proppant is 3.5kg;

[0056] (3) At...

Embodiment 3

[0059] A fracturing process for realizing large channels by using difference in proppant density, comprising the following steps:

[0060] (1) Mix the low-density proppant and the high-density proppant with the fracturing fluid base fluid respectively to obtain the low-density proppant fracturing fluid and the high-density proppant fracturing fluid, and the low-density proppant fracturing fluid The sand ratio of the proppant and high-density proppant fracturing fluid is 15%, and the density of the low-density proppant is 1.0g / cm 3 , hollow particles; the density of the high-density proppant is 2.8g / cm 3 ;

[0061] (2) Mix medium-density proppant, fiber and fracturing fluid base fluid evenly to obtain fiber-containing medium-density proppant fracturing fluid; the sand ratio of the medium-density proppant fracturing fluid is 12%, and the The medium density proppant has a density of 1.3g / cm 3 , the quality of fibers added to each cubic meter of proppant is 1.5kg;

[0062] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com