Electrode plate for improving wettability of lithium battery electrolyte and preparation method of electrode plate

A technology for electrode pole pieces and lithium batteries, which is applied in battery electrodes, non-aqueous electrolyte storage battery electrodes, and electrode manufacturing. The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

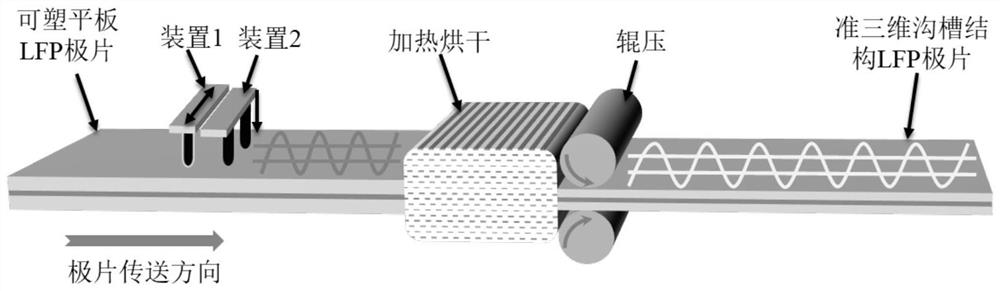

[0036] A groove structure lithium iron phosphate (LFP) positive pole piece is prepared by the following method:

[0037] (1) While moving the electrode pole piece horizontally, engrave a groove on the surface of the first surface of the electrode pole piece in a plastic state through a horizontal needle head and a corrugated needle head, and the horizontal needle head is fixedly carved to obtain a straight line stripe groove, so The corrugated needle scans and engraves back and forth to obtain the corrugated stripe groove, and then heats and dries at 100°C, and solidifies and forms to obtain the first electrode sheet with groove structure;

[0038] Among them, the shape of the horizontal needle and the corrugated needle is cylindrical, the diameter of the needle is 20 μm, the number of the horizontal needle is 1, the number of the corrugated needle is 1, and the scanning period of the corrugated needle is 0.08 milliseconds.

[0039] (2) While moving the electrode pole piece ob...

Embodiment 2

[0043] The main difference between this embodiment and embodiment 1 is that the number of horizontal needles is 2, the number of corrugated needles is 1, the diameter of the needles is 80 μm, the scanning period of the needles is 0.06 milliseconds, and the needles are heated and dried at 110° C.

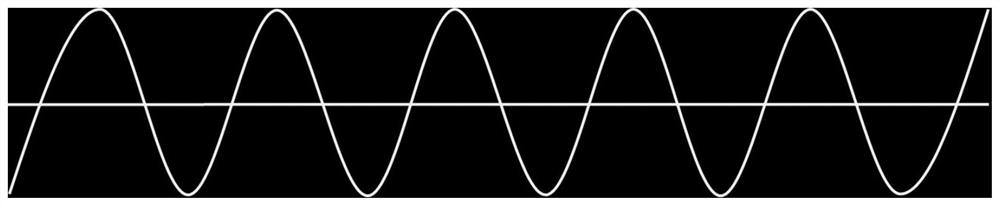

[0044] In this embodiment, the groove structure electrode pole piece is as image 3 As shown, the front and back structures of the positive electrode sheet are composed of a corrugated groove and two linear grooves cross-linked with each other, wherein the straight stripes divide the corrugated stripes into three equal parts.

Embodiment 3

[0046]The main difference between this example and Example 1 is that the number of horizontal needles is 3, the number of corrugated needles is 1, the diameter of the needles is 140 μm, the scanning period of the needles is 0.04 milliseconds, and the needles are heated and dried at 120° C.

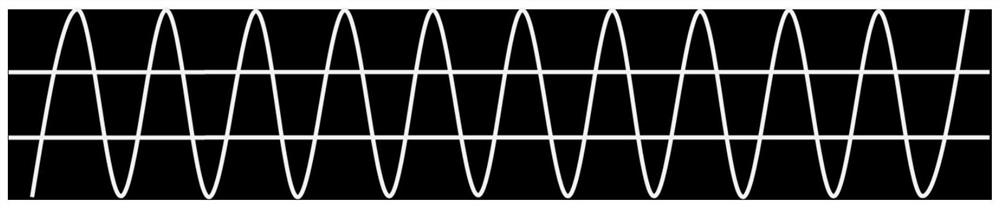

[0047] In this embodiment, the groove structure electrode pole piece is as image 3 As shown, the front and back structures of the positive pole piece are composed of one corrugated groove and three linear grooves interlinked with each other, wherein the straight stripes divide the corrugated stripes into four equal parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com