Novel ozone generator module unit

An ozone generator and module unit technology, which is applied in ozone preparation, discharge method preparation of ozone, oxygen/ozone/oxide/hydroxide, etc., can solve the problem that the ozone space temperature cannot be stabilized, the maintenance of unfavorable ozone concentration, and the thickness of the ground electrode Narrow and other problems, to achieve the effect of facilitating transportation and promotion, convenient maintenance and assembly, and reducing self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A modular plate type ozone generator water cooling unit

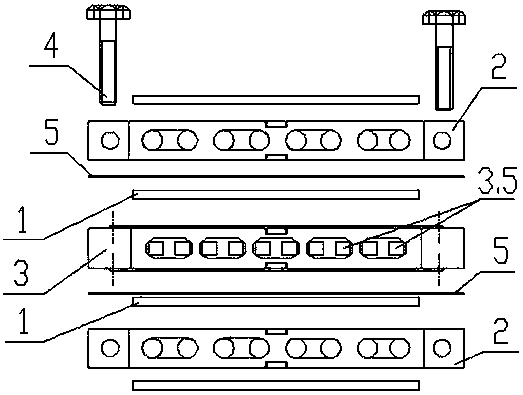

[0027] The technical solution of the present invention is achieved in this way, including a ground electrode 3, two heat conducting sheets 2 sandwiching a ground electrode, a ceramic dielectric body 1 fixed on the ground electrode, and a ground electrode between the ground electrode and the heat conducting sheet. The gasket group 5 used to adjust the gap, the ground electrode and the bolt 4 pressed by the heat conduction sheet.

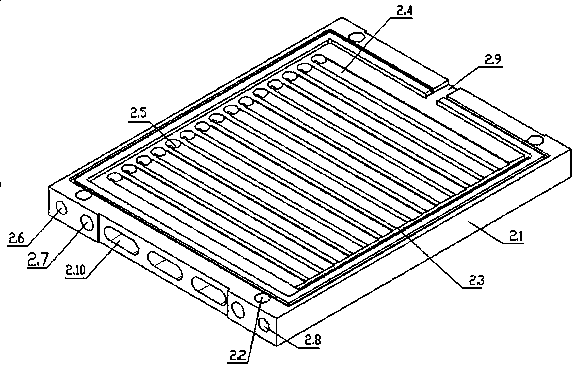

[0028] The ground electrode 3 includes a plate body 3.1, at least one strip-shaped groove 3.3 is dug on the surface of the plate body, there are through holes 3.2 penetrating the plate body around the groove, and at least one horizontal groove penetrating through the opposite side is provided on the side wall of the plate body. The cooling water flow holes 3.5 with a rectangular cross section are connected end-to-end in sequence between the cooling water flow holes 3.5, and the cooling w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com