Blocking system and blocking method for channeling inhibition in carbon dioxide non-miscible flooding of low permeability reservoir

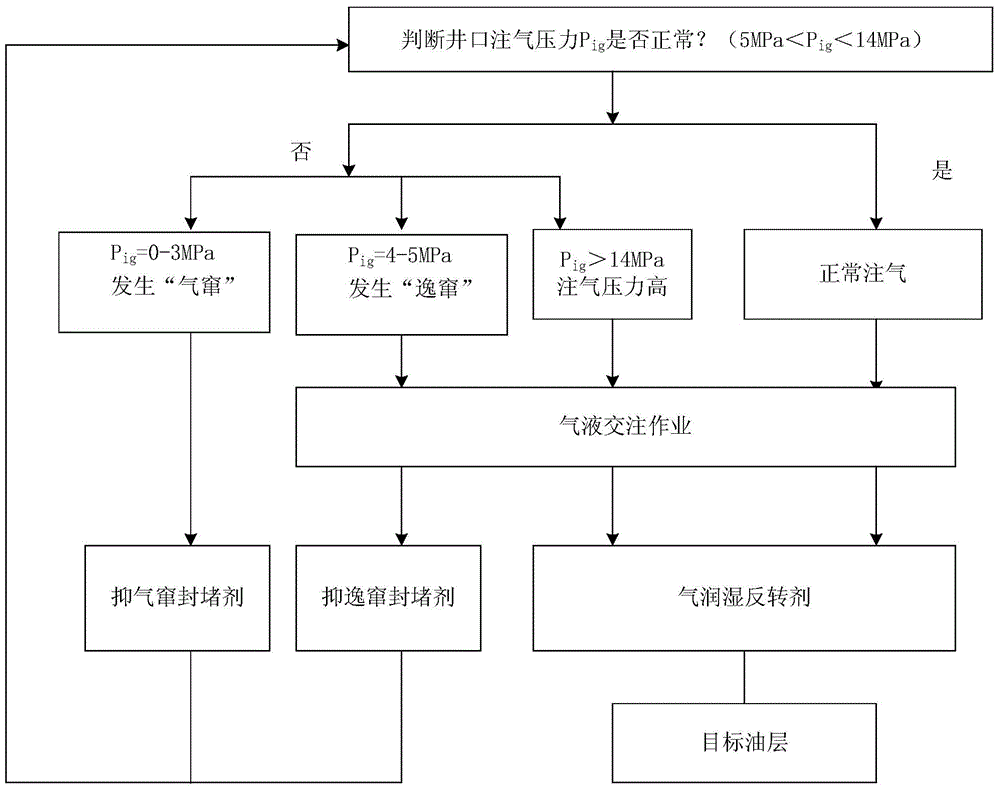

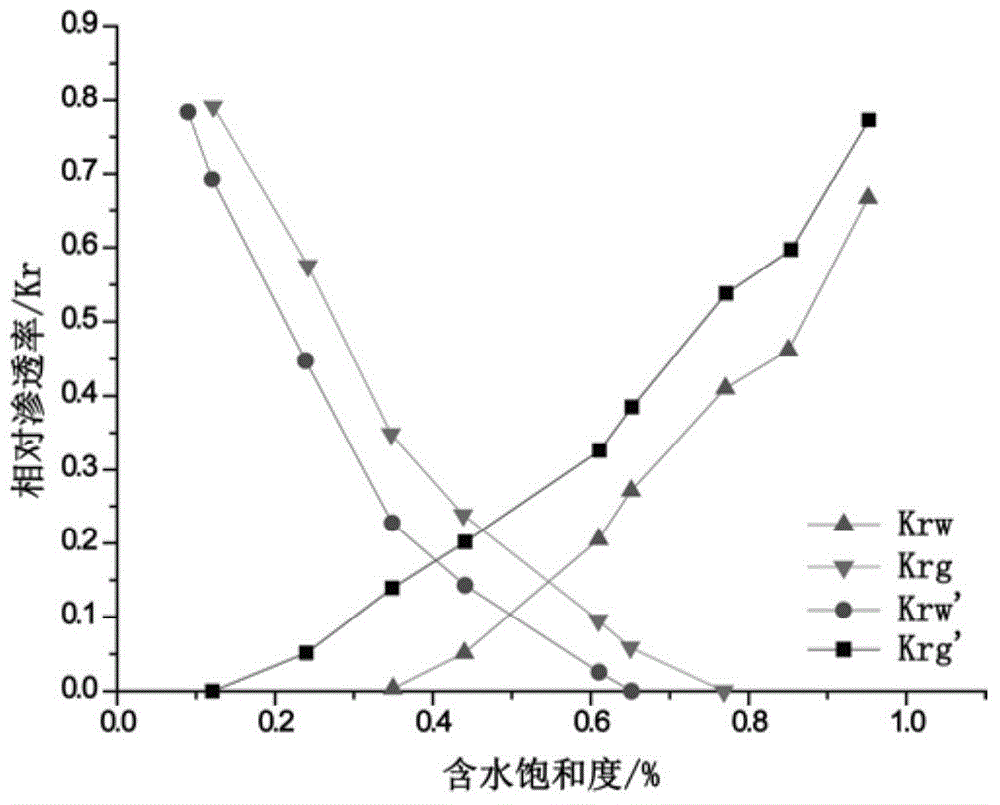

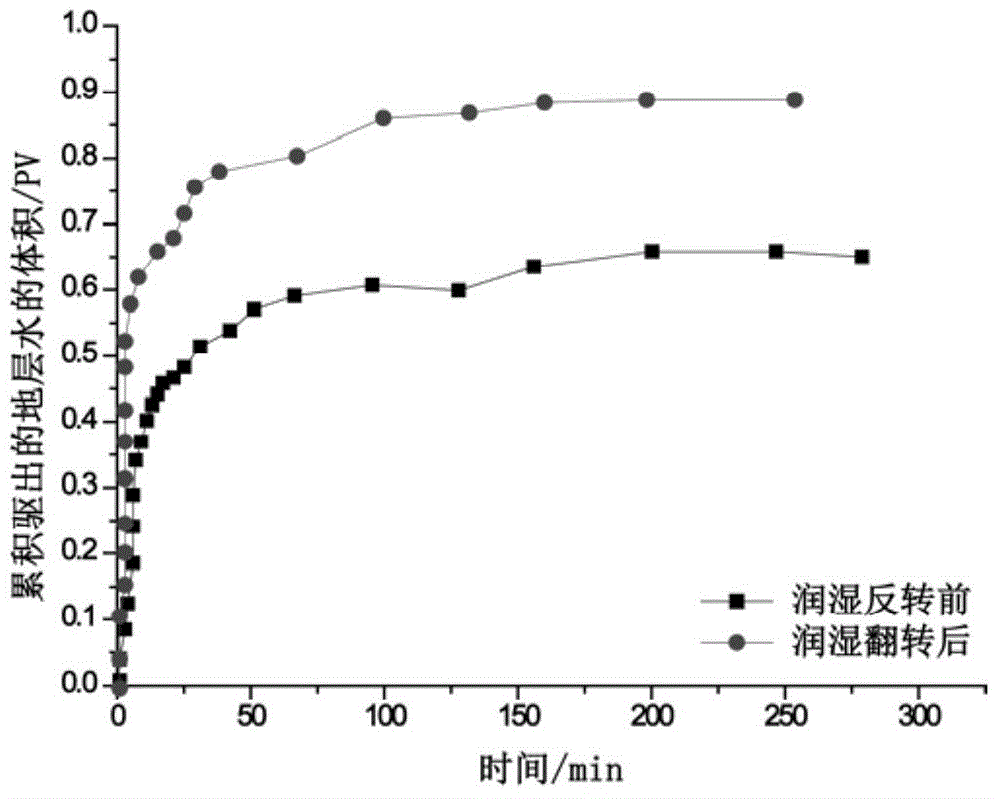

A carbon dioxide and immiscible flooding technology, applied in chemical instruments and methods, production fluids, earthwork drilling and production, etc., can solve the problems of limited plugging range, inability to inject, and low strength, so as to increase the swept volume and suppress local breakthrough , Improve the effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A carbon dioxide immiscible flooding suppression gas channeling plugging agent for low permeability reservoirs, which is made of the following raw materials: fine mineral particles, composite crosslinking agent, surfactant, polymer, retarder, oxygen scavenger and Water; each raw material consumption is as follows: the massfraction of fine mineral particles is 1%, the massfraction of composite crosslinking agent is 0.02%, the massfraction of tensio-active agent is 0.5%, the massfraction of polymer is 0.2%, retarder The mass fraction of the oxygen scavenger is 0.1%, the mass fraction of the oxygen scavenger is 0.01%, and the others are water, and the sum of the mass fractions of each component is 100%.

[0048] Among them, the fine mineral particles are wollastonite, and the particle size is 360 mesh. The composite crosslinking agent is a mixture of chromium acetate and phenolic resin, and the weight ratio of chromium acetate and phenolic resin is 0.05. The polymer is po...

Embodiment 2

[0051] A carbon dioxide immiscible flooding suppression gas channeling plugging agent for low permeability reservoirs, which is made of the following raw materials: fine mineral particles, composite crosslinking agent, surfactant, polymer, retarder, oxygen scavenger and Water; each raw material consumption is as follows: the massfraction of fine mineral particles is 2%, the massfraction of composite crosslinking agent is 0.01%, the massfraction of tensio-active agent is 0.1%, the massfraction of polymer is 0.3%, retarder The mass fraction of the oxygen scavenger is 0.04%, the mass fraction of the oxygen scavenger is 0.01%, and the others are water, and the sum of the mass fractions of each component is 100%.

[0052] Among them, the fine mineral particles are serpentine, and the particle size is 360 mesh. The composite crosslinking agent is a mixture of chromium acetate and phenolic resin, and the weight ratio of chromium acetate and phenolic resin is 0.2. The polymer is poly...

Embodiment 3

[0056] A carbon dioxide immiscible flooding inhibitor and channeling plugging agent for low-permeability oil reservoirs, which is made of the following raw materials: composite crosslinking agent, surfactant, polymer, retarder, oxygen scavenger and water; each raw material Consumption is as follows: the massfraction of composite crosslinking agent is 0.02%, the massfraction of tensio-active agent is 0.3%, the massfraction of polymer is 0.2%, the massfraction of setting retarder is 0.06%, the massfraction of oxygen scavenger is 0.01%, the others are water, and the sum of the mass fractions of each component is 100%.

[0057] Wherein, the composite crosslinking agent is a mixture of chromium acetate and phenolic resin, and the weight ratio of chromium acetate and phenolic resin is 0.1. The polymer is polyacrylamide with a molecular weight range of 12 million to 16 million. The retarder is sodium tartrate. The oxygen scavenger is sodium sulfite. Water is tap water. Surfactant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com