Production method of emulsified explosive

A technology of emulsion explosives and production methods, which is applied in the direction of explosives, etc., can solve the problems of many on-line personnel and on-line explosives, many safety hazards, and low degree of automation, and achieve the effects of improving explosive performance and storage performance and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

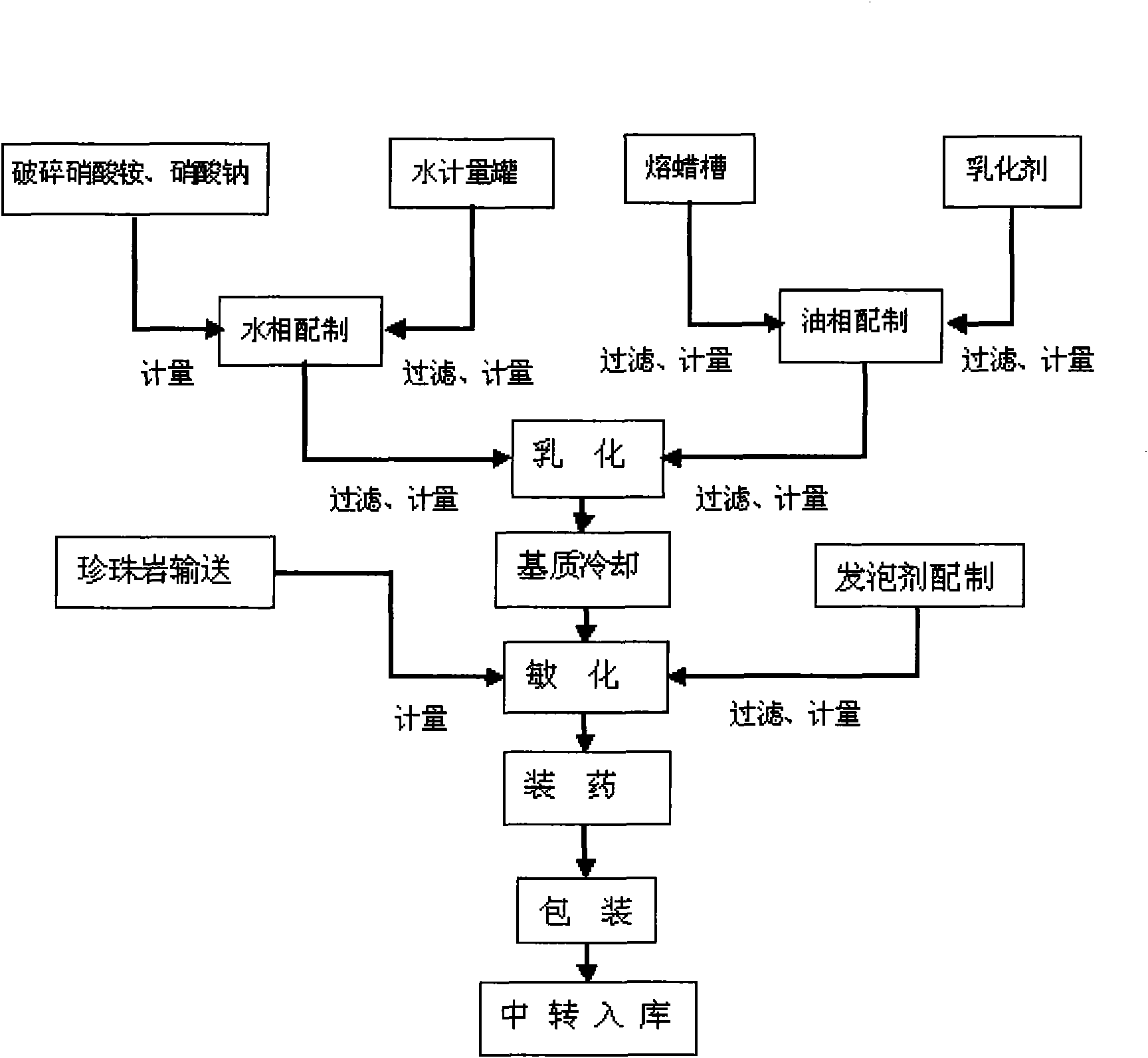

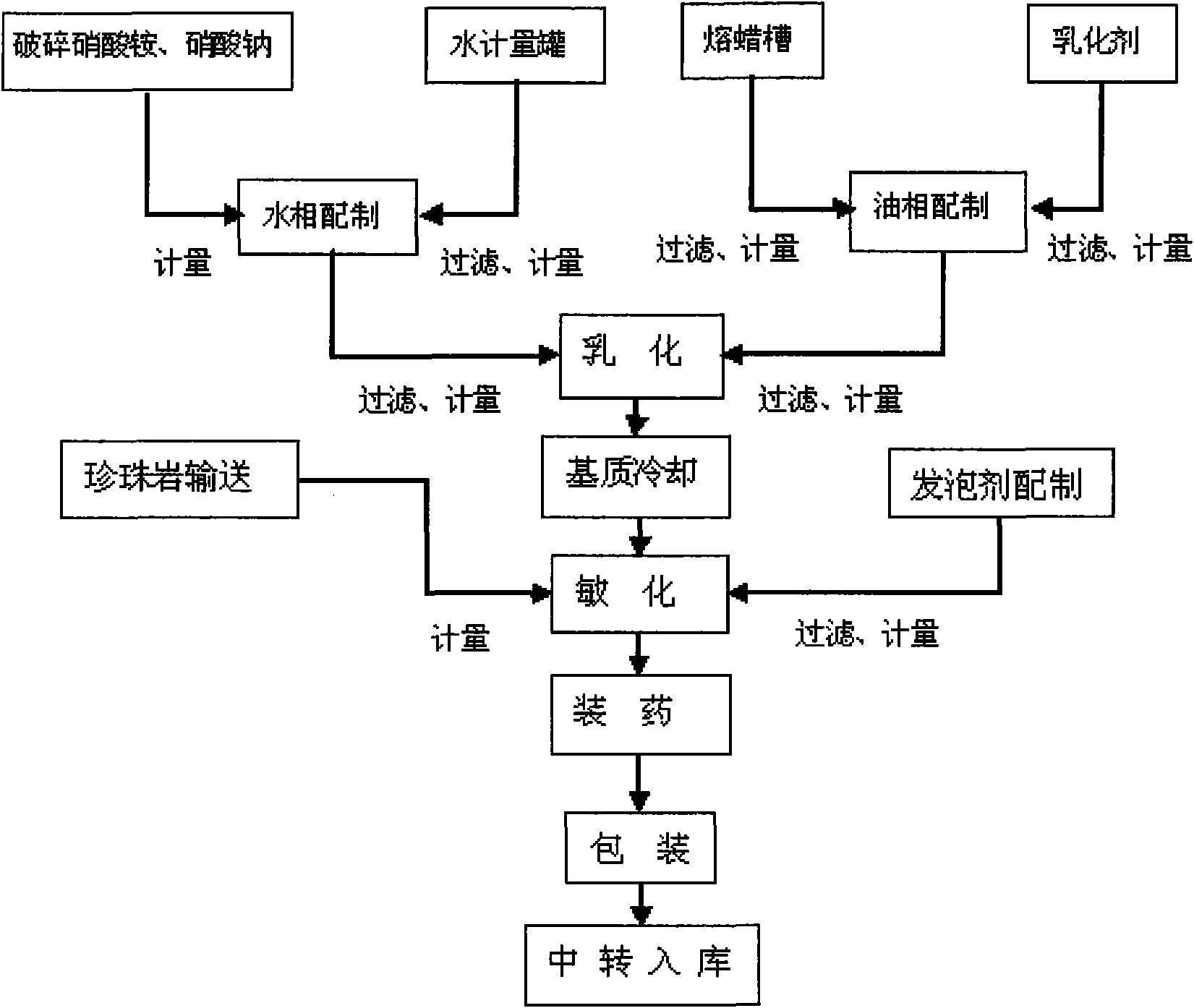

Image

Examples

Embodiment 1

[0020] Embodiment 1: as shown in accompanying drawing, a kind of production method of emulsion explosive of the present invention, the concrete steps of this method are as follows:

[0021] 1) Water phase preparation: Dissolve ammonium nitrate and sodium nitrate in water and heat to 85°C-100°C to make a water phase solution. The crystallization point of the water phase solution is 75°C-85°C, and the water phase solution contains 75% of Ammonium nitrate, 10% sodium nitrate, 15% water, all percentages are mass percentages;

[0022] 2) Oil phase preparation: Melt paraffin in a wax melting tank, then heat the molten paraffin and emulsifier to 85°C-100°C to make an oil phase solution, wherein 2 parts by weight of paraffin and 1 part by weight of emulsifier; the emulsifier is A mixture of sorbitan monopalmitate, sorbitan monooleate and sorbitan monolaurate in a weight ratio of 60:20:20;

[0023] 3) Emulsification: Add 93 parts by weight of the water phase solution and 7 parts by we...

Embodiment 2

[0031] Embodiment 2: the production method of a kind of emulsion explosive of the present invention, the concrete steps of this method are as follows:

[0032] 1) Water phase preparation: Dissolve ammonium nitrate and sodium nitrate in water and heat to 85°C-100°C to make a water phase solution. The crystallization point of the water phase solution is 75°C-85°C, and the water phase solution contains 80% of Ammonium nitrate, 8% sodium nitrate, 12% water, all percentages are mass percentages;

[0033] 2) Oil phase preparation: melt the wax in a wax melting tank, then heat the melted wax and emulsifier to 85°C to 100°C to make an oil phase solution, including 6 parts by weight of wax and 3 parts by weight of emulsifier; the emulsifier is A mixture of sorbitan monopalmitate, sodium lauryl sulfate, glyceryl stearate, anhydroxylitol monooleate in a weight ratio of 80:12:5:3; waxes of paraffin and beeswax Mixture, the weight ratio of paraffin wax and beeswax is 2: 1;

[0034] 3) Em...

Embodiment 3

[0039] Embodiment 3: the production method of a kind of emulsion explosive of the present invention, the concrete steps of this method are as follows:

[0040] 1) Water phase preparation: Dissolve ammonium nitrate and sodium nitrate in water and heat to 85°C-100°C to make a water phase solution. The crystallization point of the water phase solution is 75°C-85°C, and the water phase solution contains 78% of Ammonium nitrate, 12% sodium nitrate, 10% water, all percentages are mass percentages;

[0041] 2) Oil phase preparation: melt the wax in a wax melting tank, then heat the melted wax and emulsifier to 85°C to 100°C to make an oil phase solution, including 4 parts by weight of wax and 2 parts by weight of emulsifier; the emulsifier is The weight ratio is the mixture of mannitol synthetic fatty acid, polyisobutylene succinimide, lauryl alcohol acyl phospholipid in a weight ratio of 80:15:5; the wax is a mixture of paraffin wax, beeswax and petrolatum, and the weight ratio of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com