Vibration absorbing method for cut presplitting blasting

A pre-split blasting and pre-splitting technology is applied in the field of urban subway tunnel excavation and blasting, which can solve the problems of particularly prominent vibration phenomenon, and achieve the effect of reducing the blasting vibration speed and reducing the impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

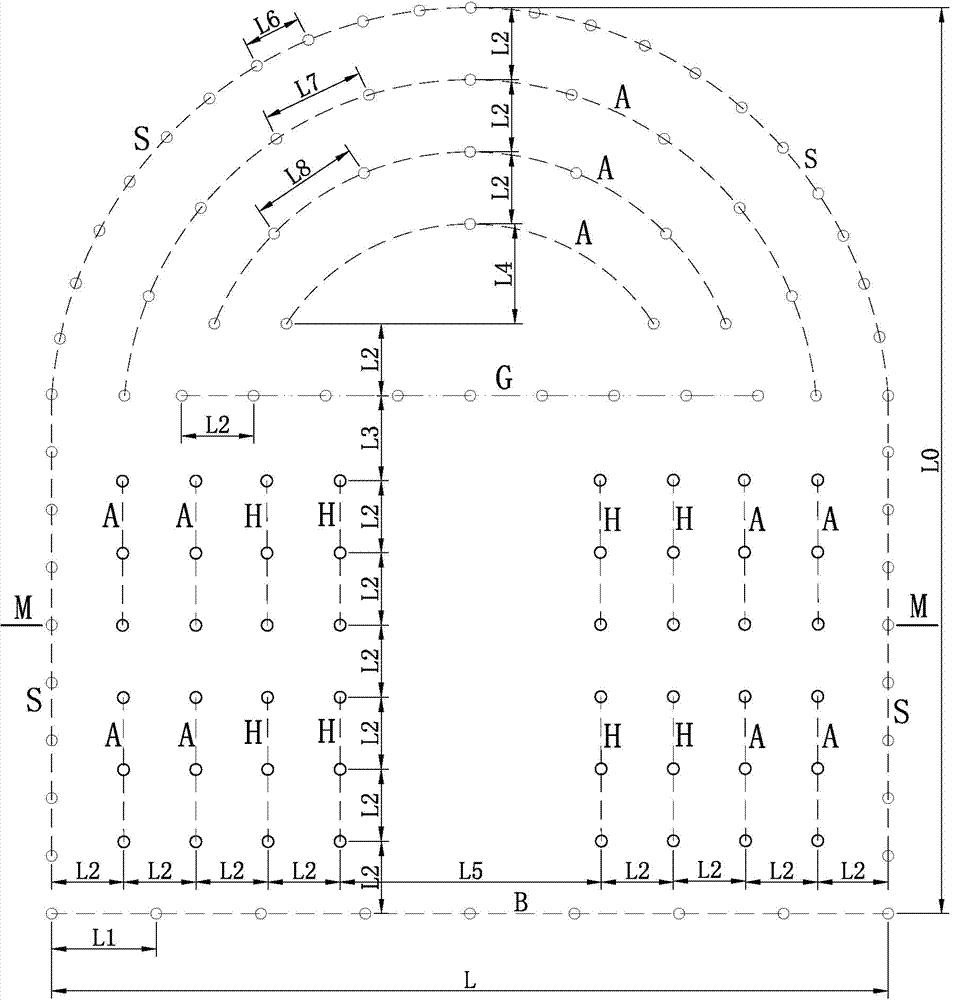

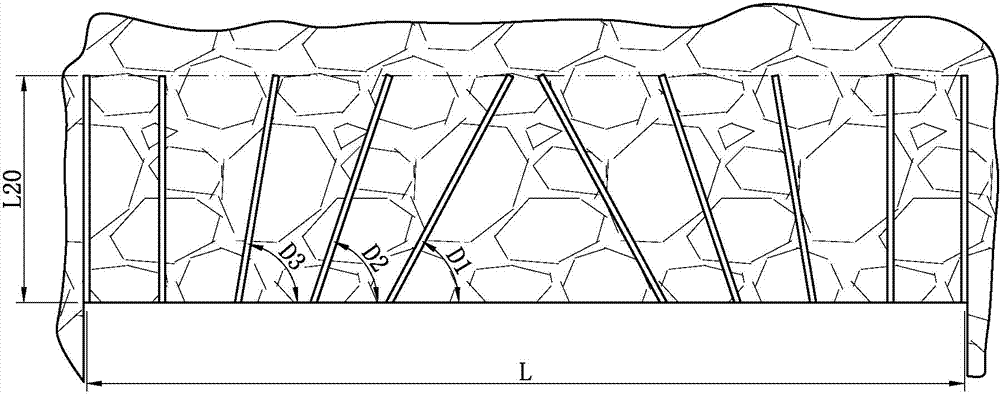

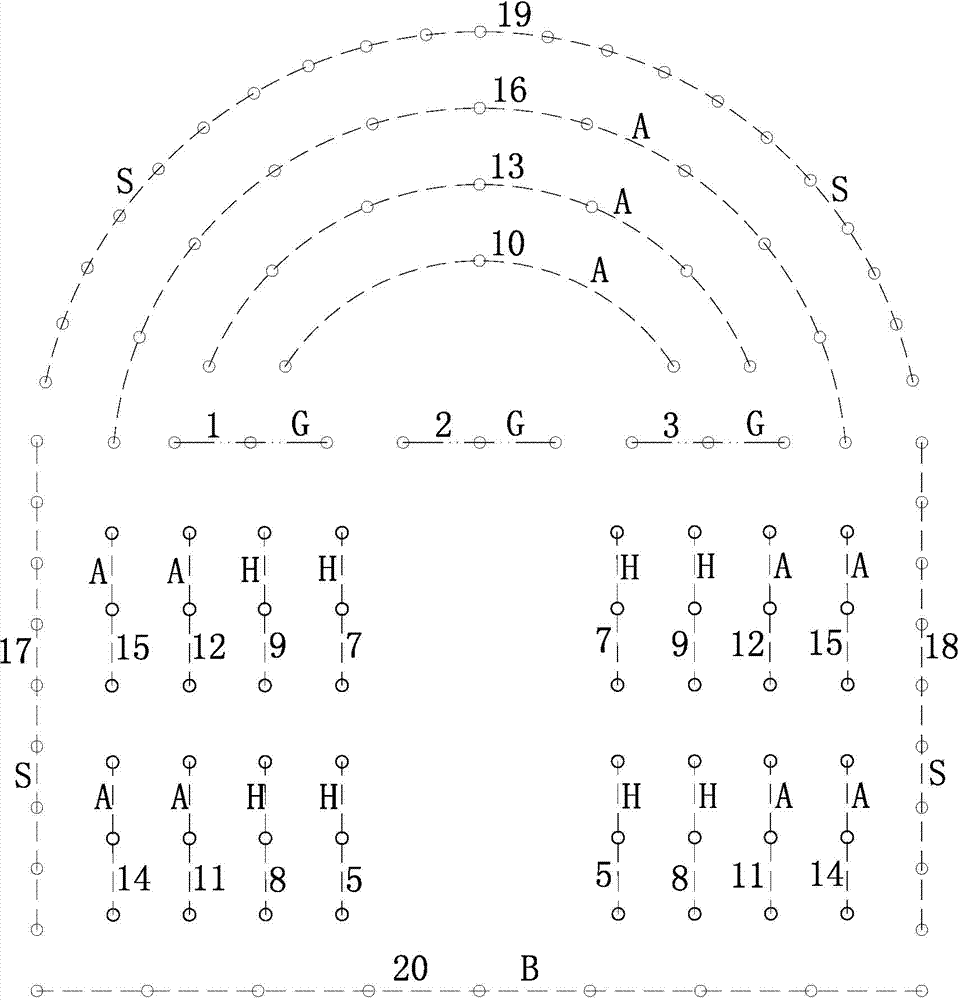

[0029] This embodiment discloses a full-section blasting scheme of a subway tunnel with a blasting excavation cycle footage of 1.5m using the cutting pre-splitting blasting shock absorption method. blastholes, auxiliary holes, peripheral holes and floor holes; the pre-splitting blastholes are a group of blastholes arranged horizontally at 500mm to 600mm above the cut hole, and the transverse spacing of the pre-splitting blastholes is 350mm to 500mm. Mixed one-piece slit charges are used for charging; slotting eyes, auxiliary eyes, peripheral eyes and bottom plate eyes are charged with ordinary emulsion explosives; the delay time is the first series of milliseconds specified in the national standard GB19417-2003 "Nel Detonator" The nonel detonator adopts the connection of millisecond nonel detonator with a segment number of 1; the detonation sequence of the blast hole is: pre-splitting blast hole, cut hole, auxiliary hole, peripheral hole and bottom plate hole.

[0030] The cut...

Embodiment 2

[0042] This embodiment discloses a blasting scheme for the upper steps of a subway tunnel with a blasting excavation cycle footage of 1.5m using the cutting pre-splitting blasting shock absorption method. blastholes, auxiliary holes, peripheral holes and floor holes; the pre-splitting blastholes are a group of blastholes arranged horizontally at 500mm to 600mm above the cut hole, and the transverse spacing of the pre-splitting blastholes is 350mm to 500mm. Mixed one-piece slit charges are used for charging; slotting eyes, auxiliary eyes, peripheral eyes and bottom plate eyes are charged with ordinary emulsion explosives; the delay time is the first series of milliseconds specified in the national standard GB19417-2003 "Nel Detonator" The nonel detonator adopts the connection of millisecond nonel detonator with a segment number of 1; the detonation sequence of the blast hole is: pre-splitting blast hole, cut hole, auxiliary hole, peripheral hole and bottom plate hole.

[0043] ...

Embodiment 3

[0054] This embodiment discloses a hybrid conjoined slitting charge used for pre-splitting blastholes with a depth of 1.5m. Slit medicine pack.

[0055] Such as Figure 8 , the mixed one-piece slotted charge includes a slotted tube, explosives, anhydrous taphole mud, water tapped clay, and detonating cord; the sidewall of the slotted tube is axially provided with two symmetrical slots 801- 1 antistatic flame-resistant PVC pipe 801, the explosive is an emulsion explosive roll; three sections of the explosive roll 802 are provided in the slit pipe, and each section of the explosive roll is connected with the detonating cord 806. Two sections of water blasting mud 803 are arranged between the explosive rolls, an anhydrous blasting mud 804 is filled at the end of the slit pipe toward the opening end of the blasthole, and sealed with waterproof black adhesive tape 805 at the end of the slit pipe toward the bottom end of the blasthole; The dimensions and specifications of each par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal spacing | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Vertical depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com