Continuous technique for preparing emulsifying explosive and charging

A production process and technology for emulsified explosives, applied in explosives processing equipment, explosives, offensive equipment, etc., can solve the problems of latex damage, high power consumption, explosion, etc., and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

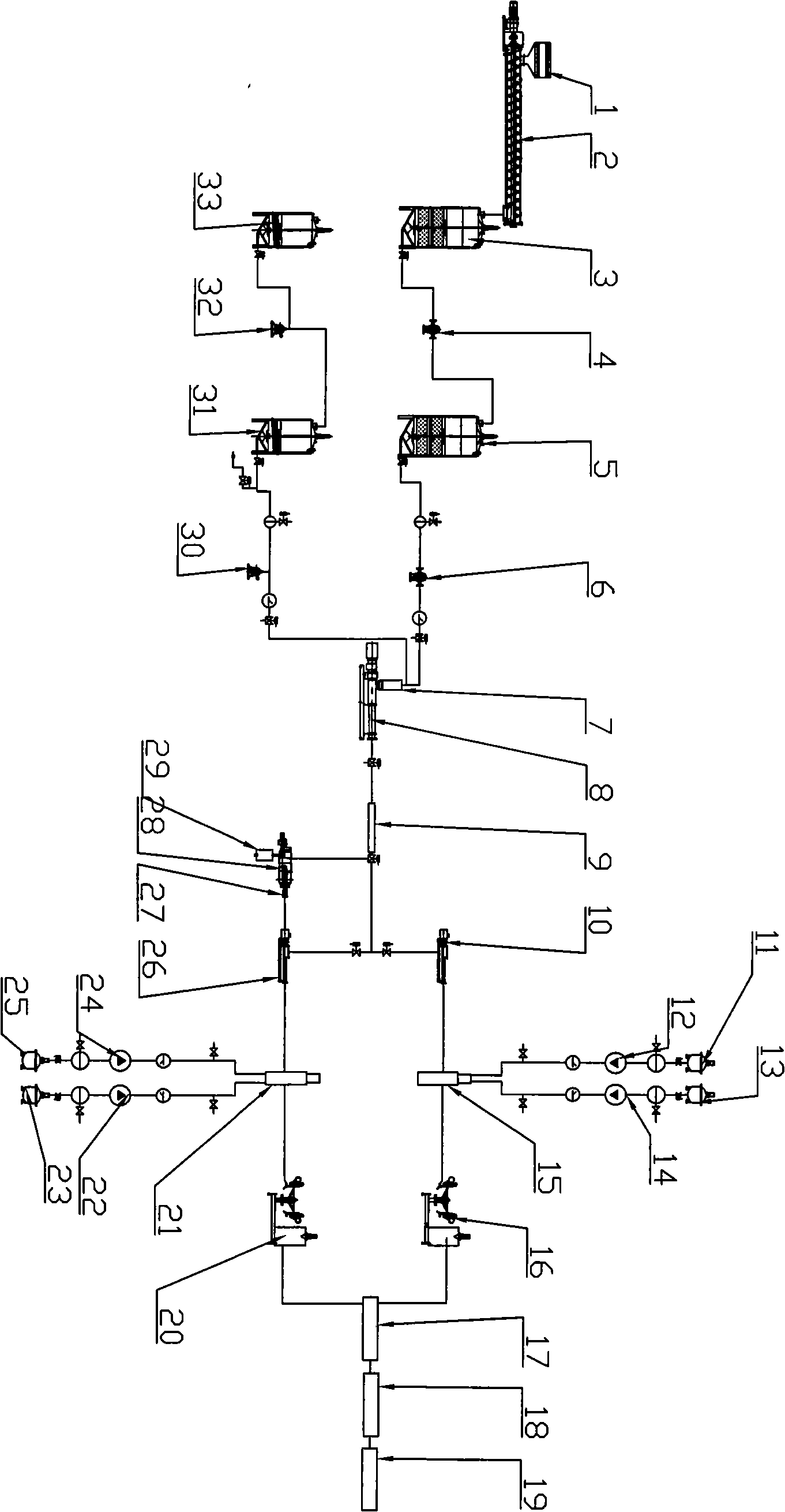

[0024] The equipment system shown in the accompanying drawings is adopted in the embodiment of the present invention. According to the process flow, the system connection sequence of the equipment is oil phase, water phase preparation system, emulsification system, sensitized charge system, cooling system and packaging system19.

[0025] In the oil phase and water phase preparation systems, the water phase preparation system includes crusher 1, screw conveyor 2, water phase melting tank 3, gear pump 4, water phase storage tank 5 and water phase pump 6; the oil phase preparation system includes oil Compatibility tank 33 , gear pump 32 , oil phase storage tank 31 and oil phase pump 30 .

[0026] The emulsification system includes a colostrum machine 7 , a matrix screw pump 8 and a static mixer 9 .

[0027] Sensitized charge systems include chemically sensitized charge systems and physical and chemical composite sensitized charge systems. Among them, the chemical sensitization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com