Titanium hydride hydrogen storage emulsion explosive

A technology of emulsified explosives and titanium hydride, which is applied in explosives, non-explosive/non-thermal agent components, offensive equipment, etc., can solve problems that have not been discovered, and achieve the effect of uniform distribution, low price and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The total mass of titanium hydride and emulsification matrix is 50 g, and the content of titanium hydride is 2% (=1 g) of the total mass. After titanium hydride was added to the emulsified matrix, the mixture was continuously stirred for 30 minutes with a stirrer, and the underwater explosion test was carried out after standing for 10 hours.

[0021] The formulation of the emulsified matrix used is the same as that of the prior art, and the basic formulation is shown in Table 1.

[0022] Table 1 The emulsification matrix formula used in Example 1

[0023] components Nitrate water Span-80 Composite oil phase other content 78 15 2 4 1

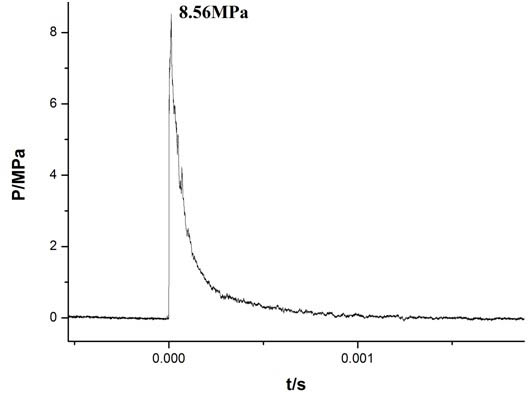

[0024] In order to conduct a comparative experiment, the matrix of the emulsion explosive was sensitized by glass microspheres, a conventional sensitizer in the production of emulsion explosives. Existing experiments have shown that: when the content of glass microspheres is 4%, the output energy of th...

Embodiment 2

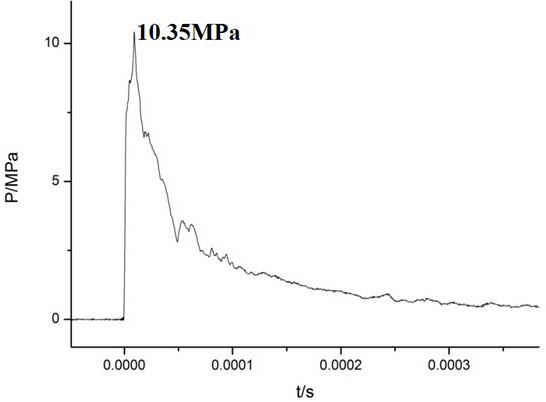

[0031] The total mass of titanium hydride and emulsification matrix is 50g, and the content of titanium hydride is 4% (=2 g) of the total mass. After titanium hydride was added to the emulsified base, it was continuously stirred with a stirrer for 25 minutes, and then the underwater explosion test was carried out after standing for 48 hours. Shock wave curve see image 3 .

[0032] The formulation of the emulsified matrix used is the same as that of the prior art, see Table 3 for details.

[0033] Table 3 The emulsified matrix formula used in Example 2

[0034] components Nitrate water LZ2731 Composite oil phase other content 77 16 2 4 1

[0035] In the underwater explosion test, the shock wave curve obtained is shown in image 3 . In the figure: the abscissa represents time (unit: s), the ordinate represents pressure (unit: MPa), and the underwater explosion shock wave curve is recorded by an oscilloscope. The test parameters are s...

Embodiment 3

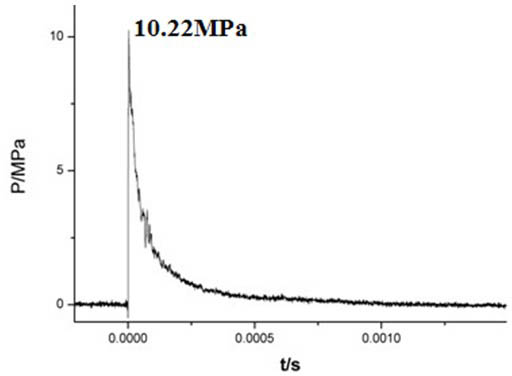

[0040] The total mass of titanium hydride and emulsification matrix is 50g, and the content of titanium hydride is 6% (=3g) of the total mass. After adding titanium hydride to the emulsification matrix, the stirrer was used to continuously stir for 25 minutes, and the underwater explosion test was carried out after standing for 25 days. The obtained shock wave curve is shown in Figure 4 .

[0041]The formulation of the emulsified matrix used is the same as that of the prior art, see Table 5 for details.

[0042] Table 5 The emulsification base formulation used in Example 3

[0043] components Nitrate water LZ2731 Composite oil phase other content 77 16 2 4 1

[0044] In the underwater explosion test, the shock wave curve obtained is shown in Figure 4 . In the figure: the abscissa represents time (unit: s), the ordinate represents pressure (unit: MPa), and the underwater explosion shock wave curve is recorded by an oscilloscope. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com