One-time well completion blasting method of measure well

A measure well, one-off technology, applied in the field of mining and mining, can solve the problems of squeezed wall surface smoothness, irrationality, inability to achieve the blasting effect of the measure well, etc., and achieve the effect of smooth well wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

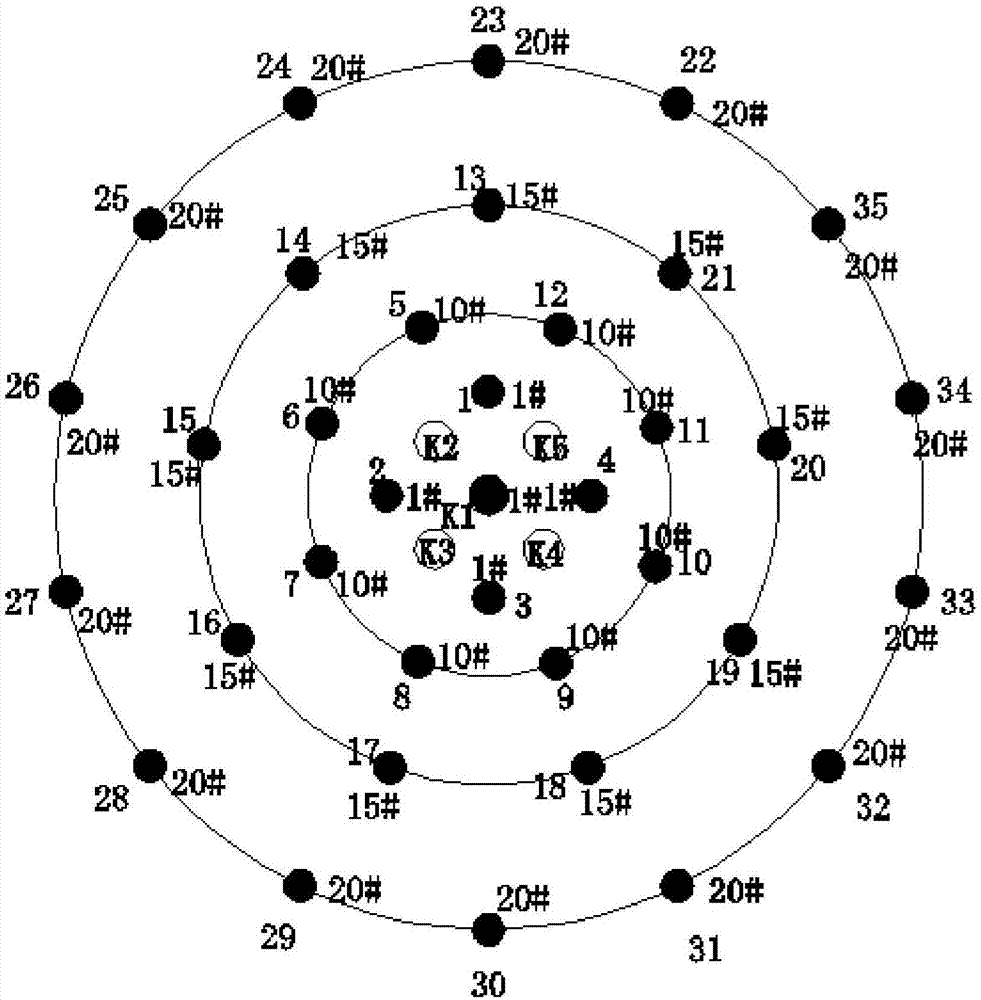

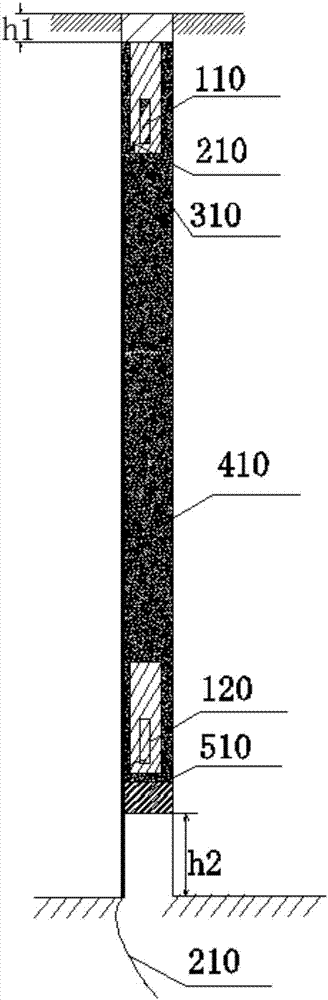

[0023] Please also see figure 1 and figure 2 ,in, figure 1 It is the blast hole design drawing of the blasting method described in the present invention; figure 2 It is a schematic diagram of the blasting charge structure of the blasting method described in the present invention. A kind of one-time blasting method for well formation provided by the invention comprises the following steps:

[0024] 1) Trolley punching: in the chamber, one central hole K1, four empty holes K2-K5, and a total of four circles of charge holes 1-35 from the inside to the outside are punched in sequence; the center hole K1 is located in the middle of the measure well position, the em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com