Static sensitization method and static sensitization equipment for packaging emulsion explosives

A technology for emulsified explosives and chemical equipment, which is applied in explosives processing equipment, explosives, offensive equipment, etc. It can solve the problems of stirring safety hazards, latex matrix demulsification, and unsafe sensitization process, so as to improve safety and simplify cooling equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

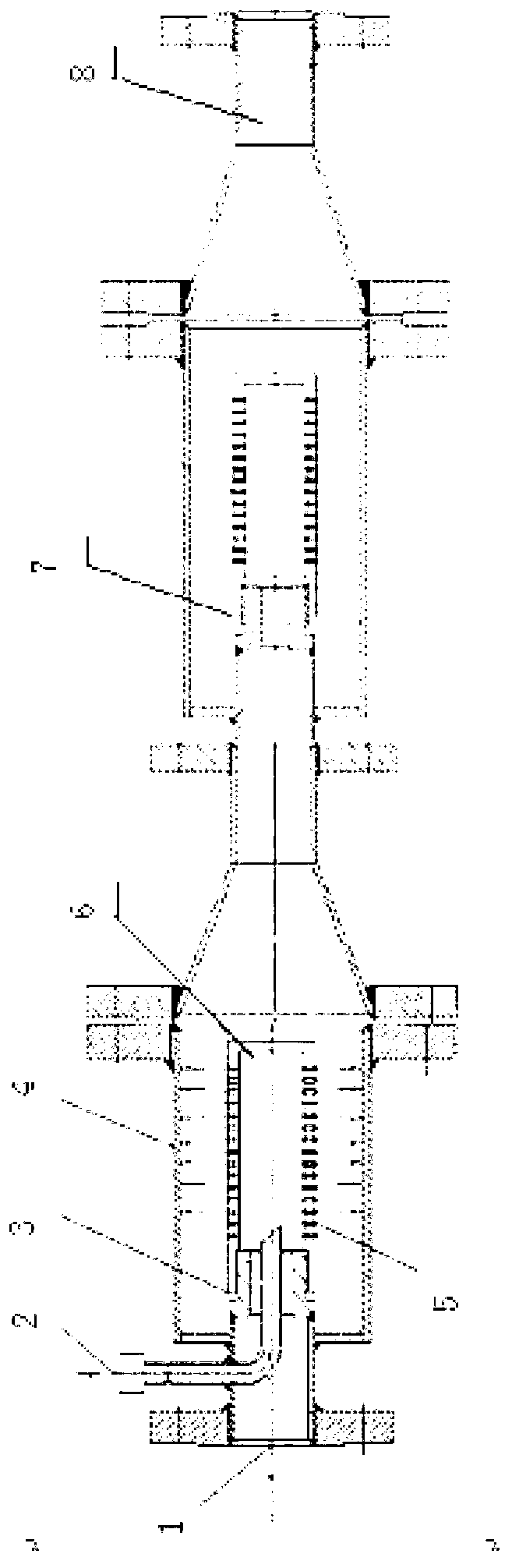

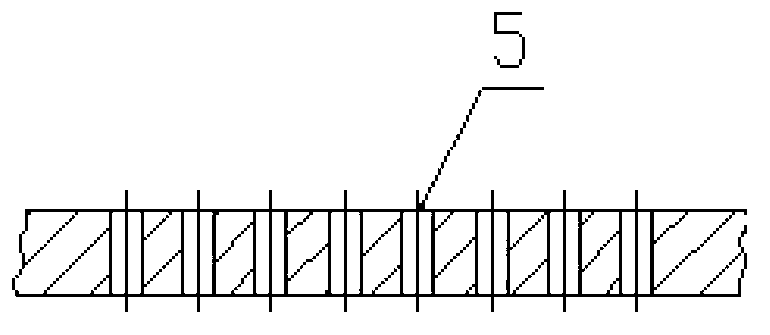

[0025] see figure 1 , 2 , the static sensitization equipment for packaging emulsion explosives includes a secondary static sensitizer, a first static sensitizer 3 and a second static sensitizer 7, the colloid feed port 1 is connected to the static sensitizer 3, and the configured water The oil phase solution passes through the emulsifier to become a latex matrix, and the latex matrix is sent to the hopper of the screw pump after being cooled by simple air cooling. The agent feed port 2, the colloid feed port 1 and the sensitizer feed port 2 are all equipped with a flow regulating valve, the latex matrix is under the pressure of 0.5-0.8Mpa, and the sensitizer is 75%-90% by weight and The ratio of 10% to 25% is mixed, the mixture flows in the pipeline, and quickly fills the resistance chamber 6. When encountering a suddenly narrowed section, the pressure of the fluid is reduced due to the resistance, and the flow layer after throttling expands into a radial shape , when th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com