Drilling-explosion-pumping triadic pressure-relief outburst-prevention method

A three-in-one, outburst prevention technology, which is applied in the fields of earthwork drilling, gas discharge, safety devices, etc., can solve the problems of heavy drilling construction workload, low outburst prevention efficiency, and small effective impact range of drilling, etc. Highlight the danger, easy to operate, and reduce the effect of outstanding potential energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

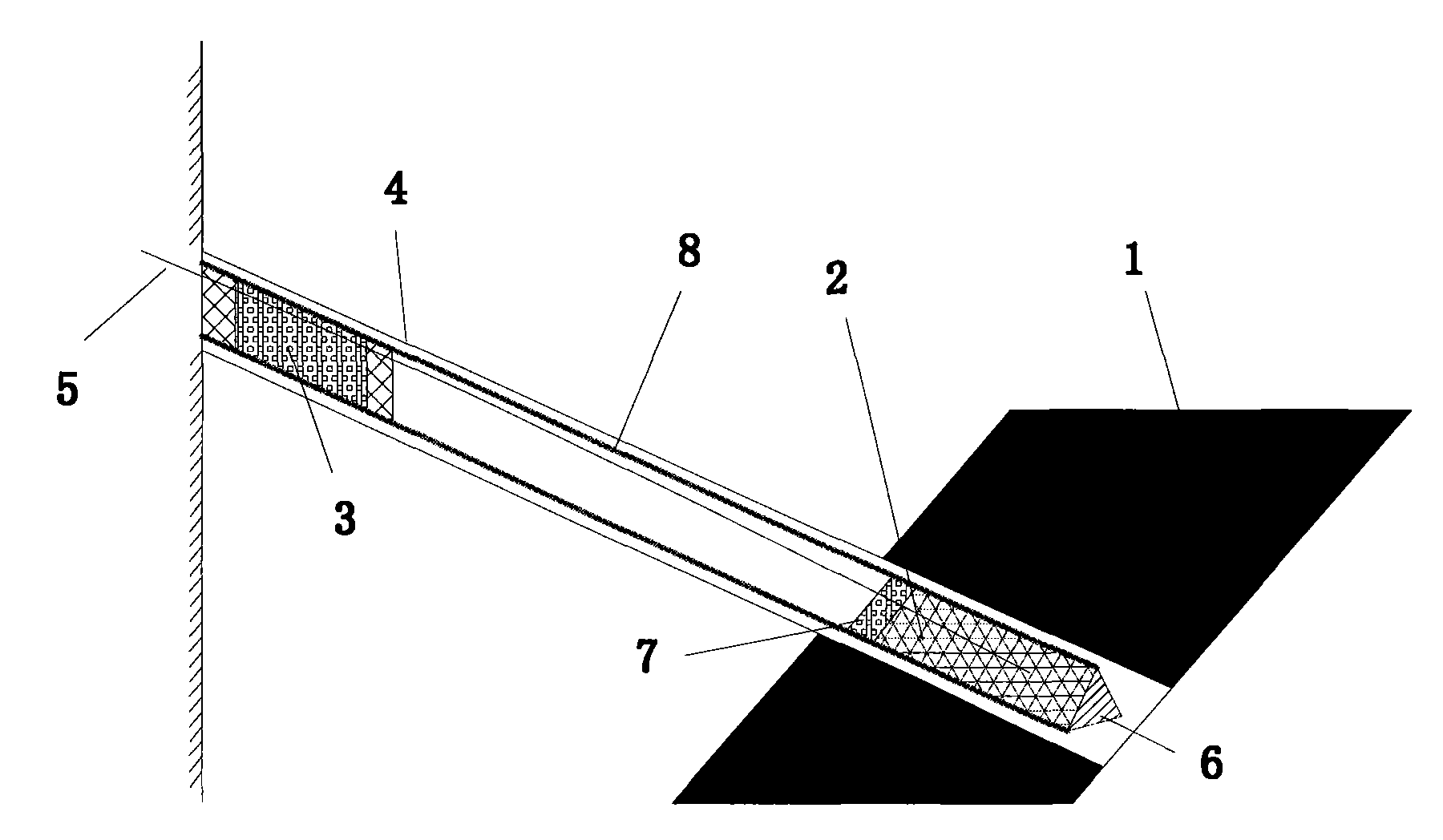

[0017] The three-in-one pressure relief and anti-outburst method of drilling, blasting and pumping of the present invention:

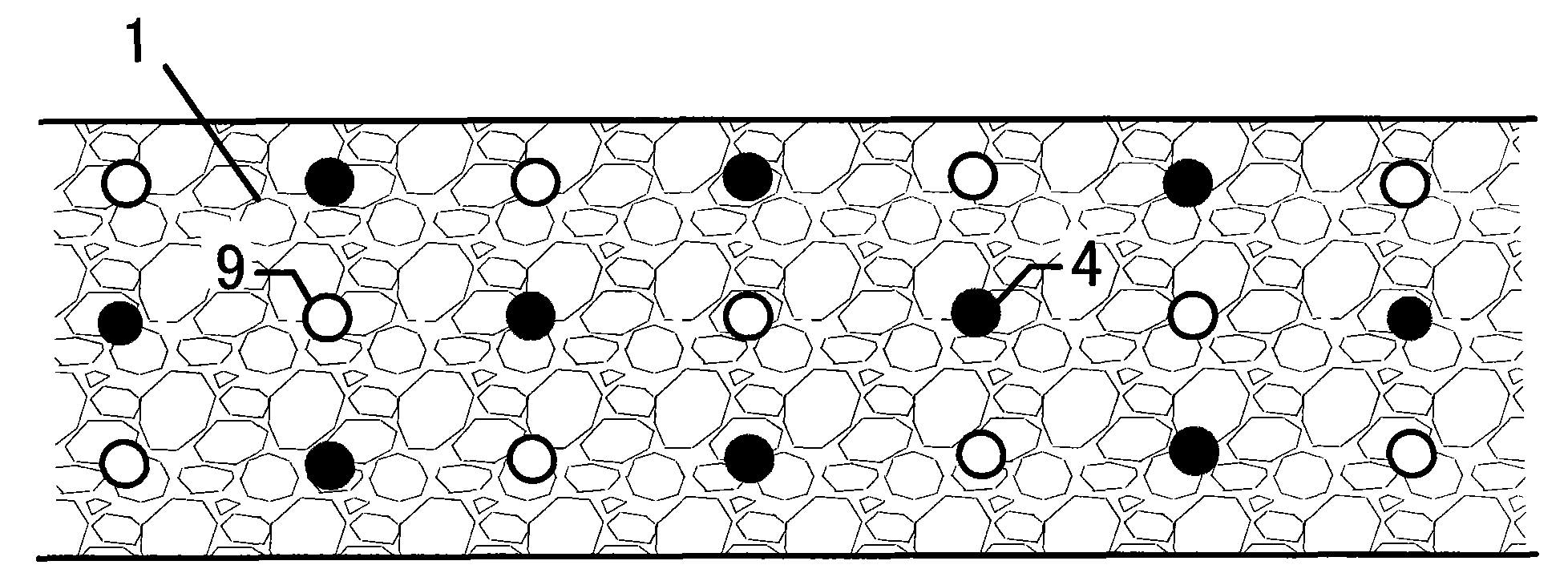

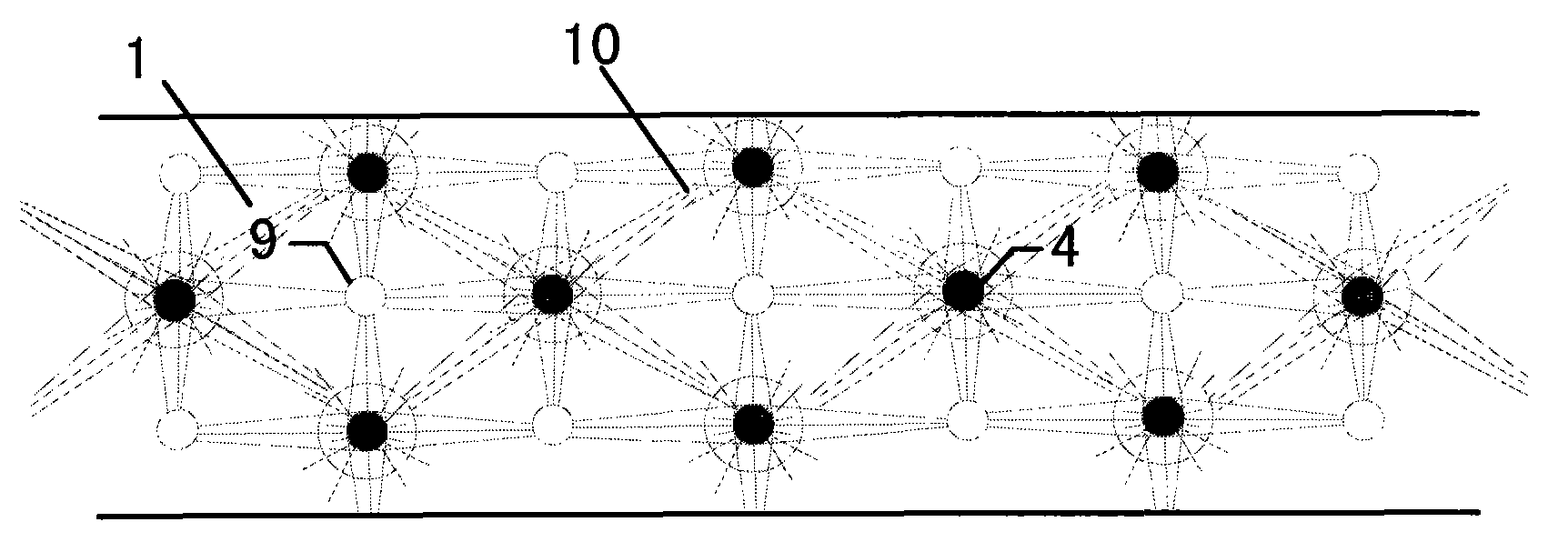

[0018] (1) On the coal seam 1 in front of the coal mining or excavation face, the control holes 9 and the blasting holes 4 are alternately arranged along the bedding or through the bedding; a single row or multiple rows are arranged to drill several long boreholes. Ordinary drilling construction technology is basically the same, you can choose spiral or round drill pipe according to your needs;

[0019] (2) First carry out construction work on alternately arranged control holes 9 one by one. The depth of the control holes 9 along the bedding is 8-15m, and the depth of the through-bedding drilling is 20-40m. hole operation, and connect the borehole to the drainage pipe network through the drainage hole pipe, manifold pipe and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com