Room-temperature CO2 switch type compound emulsifier

A compound emulsifier and carbon dioxide technology, applied in chemical instruments and methods, chemical/physical processes, dissolution, etc., can solve the problems of high energy consumption, unfavorable heat-sensitive compounds, etc., and achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

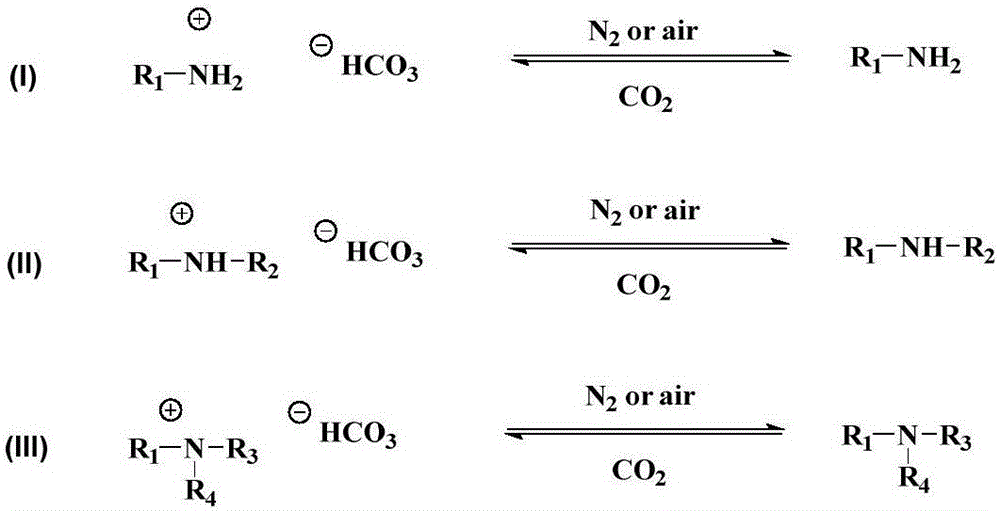

Method used

Image

Examples

Embodiment 1

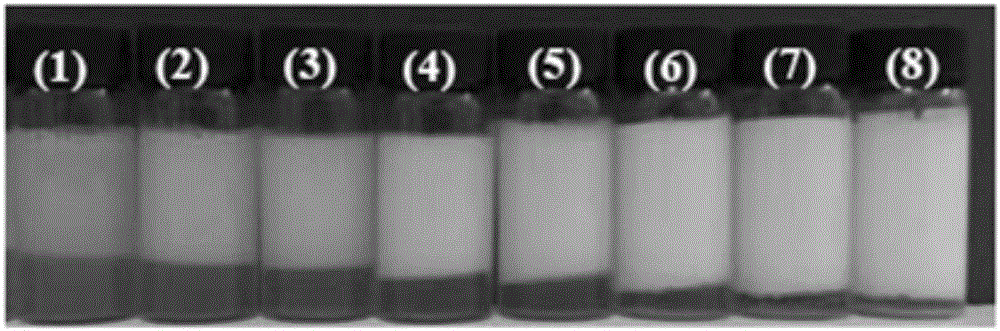

[0020] Example 1: CO 2 / N 2 Surface activation of nano-silica particles by switch-type surfactants. Take 7mL of surfactant aqueous solutions with a series of concentrations and put them into 25mL columnar vials, add 0.035g of commercial nano-silica particles (HL-220, the primary particle size is about 20nm, and the BET specific surface area is 200m 2 / g, produced by Wuxi Jinding Longhua Chemical Co., Ltd.), disperse the particles with an ultrasonic disperser (JYD-650, Shanghai), add 7mL of n-decane, emulsify with a high-shear emulsifier for 2min, and obtain a stable O / W Pickering Emulsion, the appearance photographs and micrographs of the emulsion were taken after standing for one week. Figure 5 The micrographs show that compared with the surfactant alone, the nanoparticles and the surfactant at a very low concentration can stabilize the emulsion. decrease, indicating that these emulsion nanoparticles are stable. The relevant mechanism of action is as follows: nano-silica...

Embodiment 2

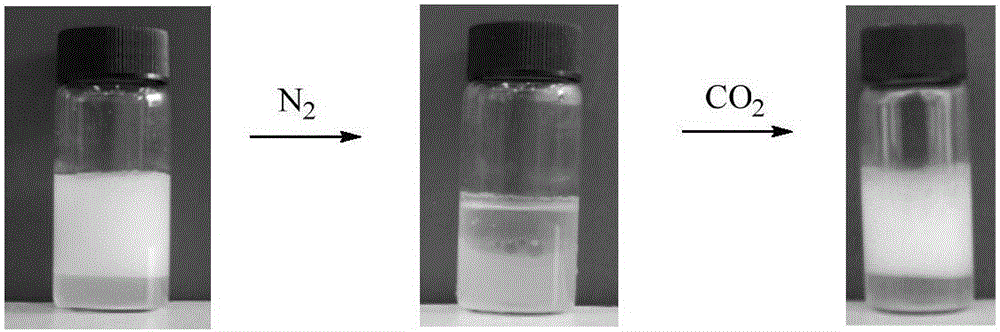

[0021] Example 2: CO of Pickering emulsions at room temperature 2 / N 2 Responsive validation. Ultrasonically disperse 0.035g of nano-silica particles in 7mL of surfactant aqueous solution (concentration: 0.01mM), add 7mL of n-decane, and homogeneously emulsify with a high-shear emulsifier for 2min to obtain a stable O / W Pickering emulsion liquid. Bubble N into the emulsion at room temperature 2 After one hour, the emulsion breaks and the oil and water separate. When the solution was bubbled with CO at room temperature 2 , the surfactant intermediate is reprotonated, and then adsorbed to the surface of the silica particles, endowing the particles with surface activity, and the particles can stabilize the emulsion. This can be repeated many times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com