Corrosion-resistant steel for chain plates and manufacturing method of corrosion-resistant steel

A manufacturing method and corrosion-resistant technology, applied in the field of material processing, can solve the problems of low carbon content of 16Mn steel chain plate, complicated process, unsuitable for hot-rolled plate processing and manufacturing chain plate, etc. Corrosion-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Below by embodiment the present invention will be further described.

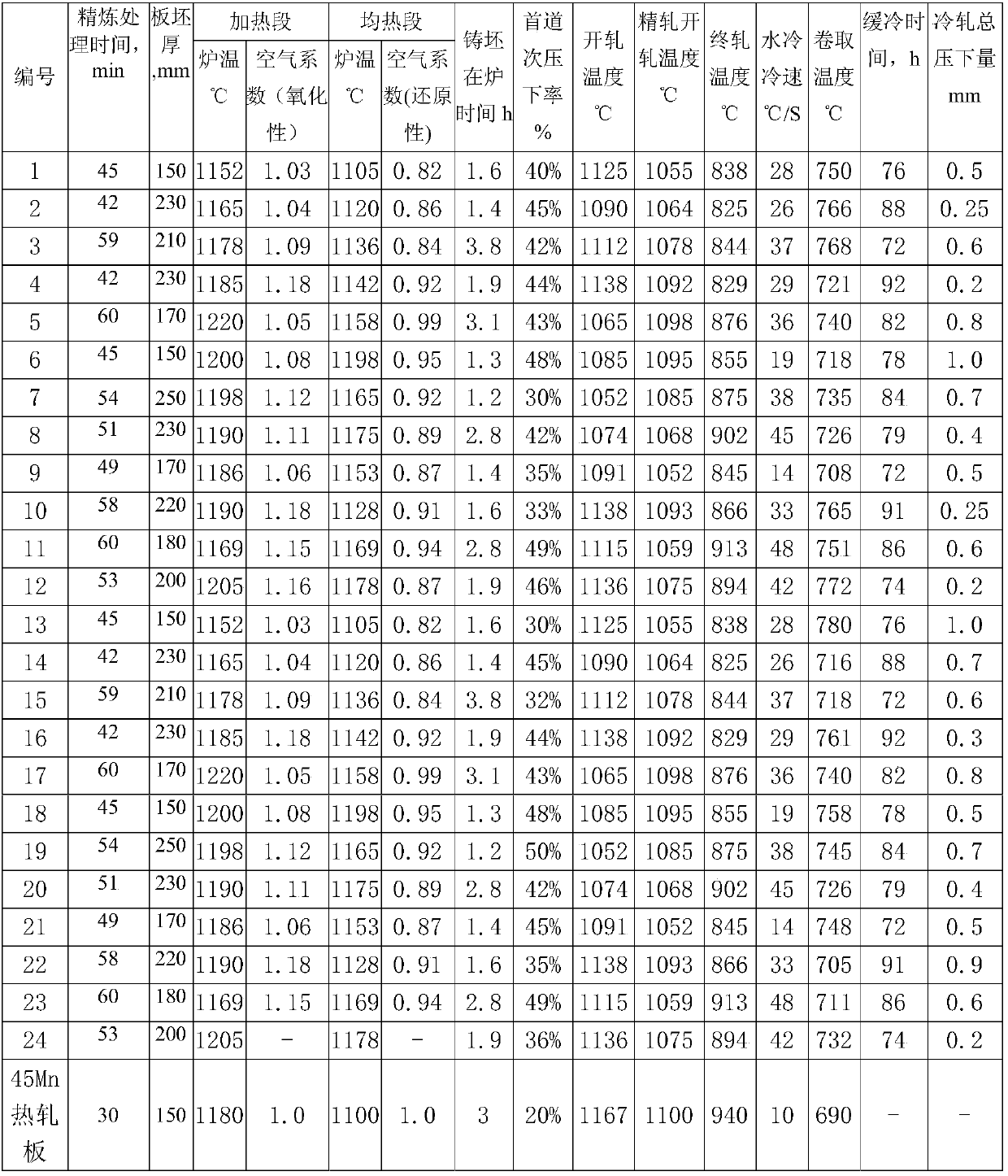

[0055] The embodiments of the present invention carry out smelting, refining, continuous casting, continuous casting, rolling and cold rolling according to the composition ratio of the technical solution.

[0056] (1) Smelting process: LF+RH double refining treatment is adopted, and the treatment time is required to be more than 40 minutes, so that the non-metallic inclusions can fully float up, ensure the quality of molten steel, and improve the fatigue performance of the finished chain plate;

[0057] (2) Rolling:

[0058] a) Hot feeding and hot charging after continuous casting; hot rolling and hot charging after continuous casting; high-pressure water descaling is used before finishing and rough rolling, and the working pressure of high-pressure water is greater than 200MPa to ensure the surface quality of the finished steel plate; The rolling temperature is 1050°C-1150°C, the reduction rate of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| spheroidization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com