Overlaying repair method for worn roller

A repair method and roll technology are applied in the field of surfacing repair of worn parts and surfacing repair of worn rolls, which can solve the problems of decreased wear resistance of rolls, shortened service life of surfacing repaired rolls, poor hardness uniformity of surfacing repaired layers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

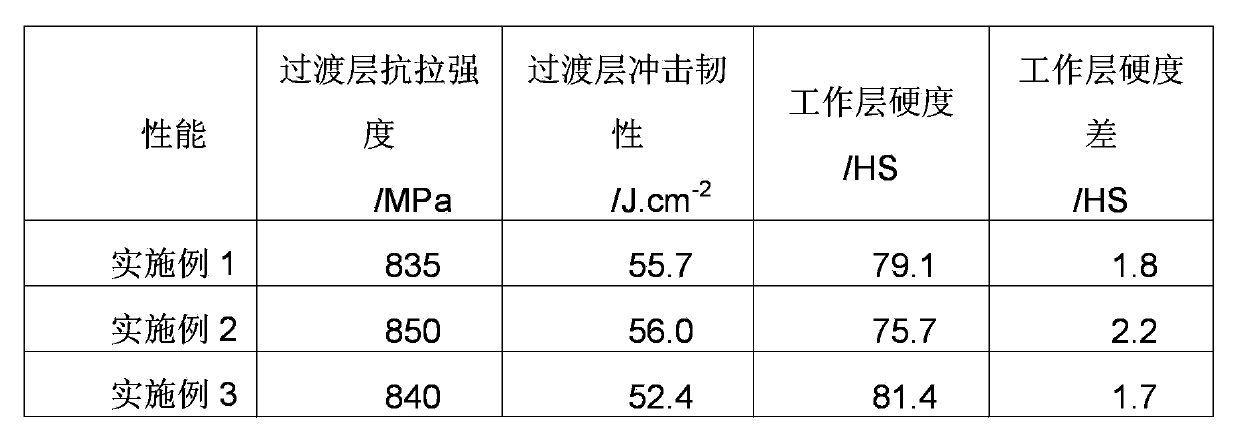

Examples

Embodiment 1

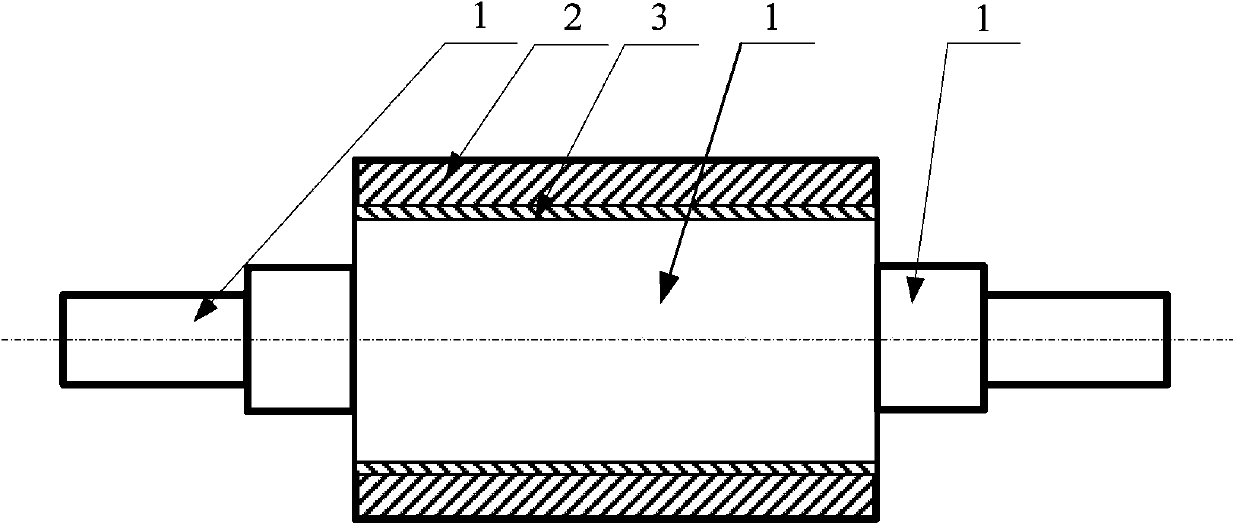

[0025] A surfacing welding repair method for a worn roll with a roll diameter of φ350mm, comprising the following process steps: first turning the worn surface of the worn roll, then surfacing a high-strength and tough transition layer on the processed surface, and then surfacing a wear-resistant transition layer on the transition layer The working layer is then heat-treated to the surfacing roll, and finally finished to the specified size and precision. Its specific process steps are:

[0026] ① Turn the worn surface of the worn roll to remove all cracks and holes to obtain a smooth worn surface of the roll.

[0027] ② Then surfacing a high-strength transition layer on the processed surface of the above-mentioned worn roll, and its thickness is controlled at 3.5mm, and then surfacing a wear-resistant working layer on the transition layer, its thickness is controlled at 35mm. During the surfacing process of the roll, the roll The body temperature is controlled at 380°C.

[0...

Embodiment 2

[0030] A surfacing welding repair method for a worn roll with a roll diameter of φ380mm, comprising the following process steps: first turning the worn surface of the worn roll, then surfacing a high-strength and tough transition layer on the processed surface, and then surfacing a wear-resistant transition layer on the transition layer The working layer is then heat-treated to the surfacing roll, and finally finished to the specified size and precision. Its specific process steps are:

[0031] ① Turn the worn surface of the worn roll to remove all cracks and holes to obtain a smooth worn surface of the roll.

[0032] ② Then surfacing a high-strength and tough transition layer on the processed surface of the above-mentioned worn roll, the thickness of which is controlled at 5mm, and then a wear-resistant working layer is surfacing on the transition layer, and its thickness is controlled at 45mm. During the surfacing process of the roll, the roll body The temperature is contro...

Embodiment 3

[0035] A surfacing welding repair method for a worn roll with a roll diameter of φ300mm, comprising the following process steps: first turning the worn surface of the worn roll, then surfacing a high-strength and tough transition layer on the processed surface, and then surfacing a wear-resistant transition layer on the transition layer The working layer is then heat-treated to the surfacing roll, and finally finished to the specified size and precision. Its specific process steps are:

[0036] ① Turn the worn surface of the worn roll to remove all cracks and holes to obtain a smooth worn surface of the roll.

[0037] ② Then surfacing a high-strength and tough transition layer on the processed surface of the above-mentioned worn roll, the thickness of which is controlled at 3mm, and then a wear-resistant working layer is surfacing on the transition layer, and its thickness is controlled at 20mm. During the surfacing process of the roll, the roll body The temperature is contro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com