High-strength spheroidal graphite cast iron for thick-walled casting die

A ductile iron, high-strength technology, applied in the field of casting materials, can solve the problems of anti-whitening, reduction of elongation and plasticity, and deterioration of mechanical properties of ductile iron, and achieve good elongation, uniform cross-sectional hardness, and uniform structure Effect

Inactive Publication Date: 2011-07-20

BAOSHAN IRON & STEEL CO LTD +1

View PDF1 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At the same time, due to the redistribution of solute elements during solidification, there will be a series of problems such as serious element segregation, intergranular carbides, and anti-whitening. As a result, the mechanical properties of ductile iron will deteriorate, especially the elongation and plasticity. reduced, thus restricting the popularization and use of large-section ductile iron

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-4

[0049] Table 1 Embodiment 1-4 Corresponding high-strength nodular cast iron composition mass percentage except the balance Fe

[0050]

[0051] Mo

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| mechanical performance | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses high-strength spheroidal graphite cast iron for a thick-walled casting die, which comprises the following main components in percentage by mass: 3.20 to 3.50 percent of C, 1.90 to 2.20 percent of Si, 0.20 to 0.50 percent of Mn, 0.40 to 0.60 percent of Cu, 0.40 to 0.80 percent of Mo, 0.60 to 0.80 percent of Ni, less than or equal to 0.06 percent of P, less than or equal to 0.03 percent of S, 0.02 to 0.05 percent of Mg, less than or equal to 0.07 percent of Re and the balance of Fe and other inevitable impurities. The as-cast mechanical properties of the spheroidal graphite cast iron are that: sigma b is more than or equal to 750MPa, sigma 0.2 is more than or equal to 520MPa, delta is more than or equal to 3 percent, and Brinell hardness is 190 to 240; the mechanical properties of the normalized, hardened and tempered spheroidal graphite cast iron are that: the sigma b is more than or equal to 1,000MPa, the sigma 0.2 is more than or equal to 900MPa, the delta is more than or equal to 2 percent, and the Brinell hardness is 260 to 300; and the material has high strength, hardness and elongation, has uniform section hardness and structure after the material is hardened and tempered when used for a large-section die, and can meet the requirement of the actual use working condition of the large-section die with the wall thickness of more than 200mm.

Description

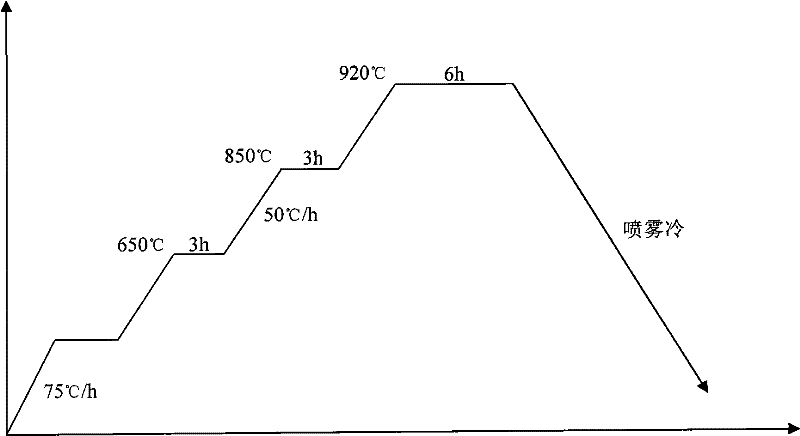

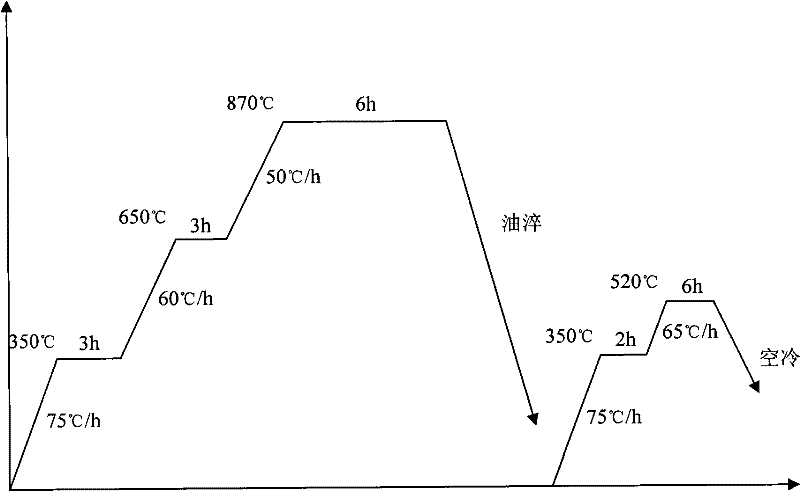

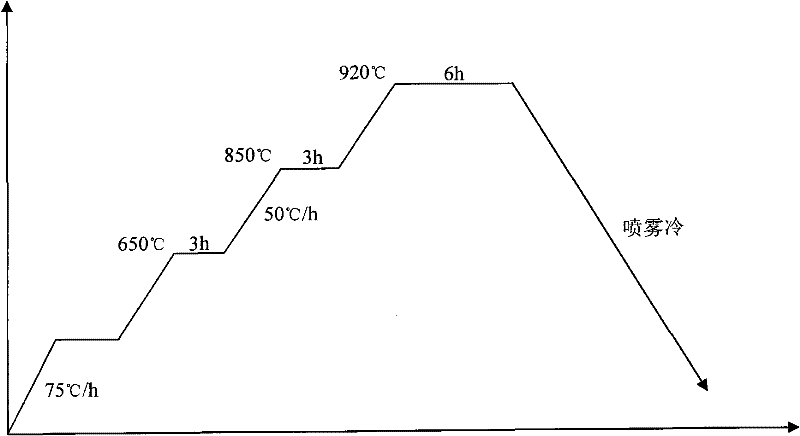

technical field [0001] The invention belongs to the technical field of casting materials and relates to a high-strength nodular cast iron used for molds of thick-walled parts. Background technique [0002] The most fundamental principle of mold design is to meet the requirements of the use target. These requirements include the main mechanical properties such as strength and toughness and other related process properties. For molds, compared with alloy steel and cast steel, ductile iron has higher strength, toughness and wear resistance, and its comprehensive performance is good. At the same time, it is suitable for mass production due to its low cost. In addition, there are precedents of using ductile iron materials such as large stamping dies and crankshafts at home and abroad. Patent Publication No. CN1506485 titled "High-strength Alloy Ductile Iron Crankshaft New Material and Its Production Method" discloses a high-strength alloy ductile iron crankshaft material. 2.04-...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C37/10

Inventor 张恒王以春温宏权

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com