Wear-resistant crosslinked PE (Polyethylene) composite pipe and manufacturing method thereof

A composite pipe and cross-linking accelerator technology, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of difficult extrusion molding, low production efficiency, no improvement in heat resistance, and achieve balanced hardness, easy operation, The effect of balanced intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

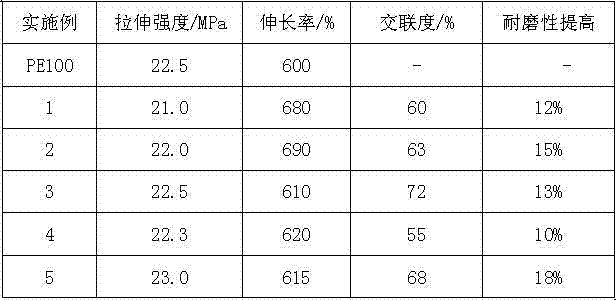

[0026] The technical solutions and effects of the present invention will be further described below in conjunction with the examples, but the specific methods, formulations and illustrations used are not limitations of the present invention.

[0027] Implementation example 1:

[0028] With 100 parts of polyethylene (PE100), 3 parts of IRGASURF SR100 of Ciba Specialty Chemicals, 5 parts of metallocene ethylene-octene copolymer elastomer, 0.2 part of antioxidant 1010, 0.5 part of PE wax of lubricant, crosslinking accelerator Add 1 part of magnesium chloride, mix the 6 kinds of materials uniformly in a high-speed mixer, and then use a twin-screw extruder with a screw diameter of 75 mm and a length-to-diameter ratio of 40:1 to melt and extrude, and the extrusion temperature is 200 ° C. Finally, dry it in a vacuum dryer with a relative vacuum degree of -0.095MPa and a heating temperature of 65°C for 4 hours. The moisture content is measured at 180ppm, and then add 2 parts of si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com