Nitrogen-added 20MnCr5 gear steel and production method thereof

A 20mncr5, production method technology, applied in the field of metallurgical manufacturing, can solve the problems of unfavorable hardenability narrow-band control, wide alloy content control range, no production control method, etc., achieve good composition uniformity and reduce composition segregation , The effect of narrowing the hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

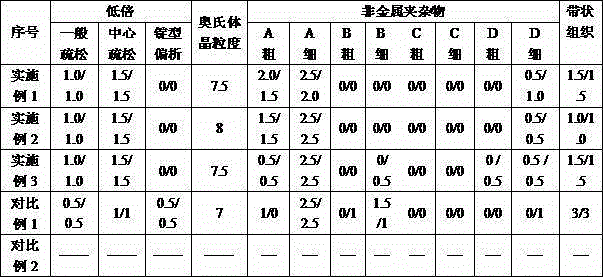

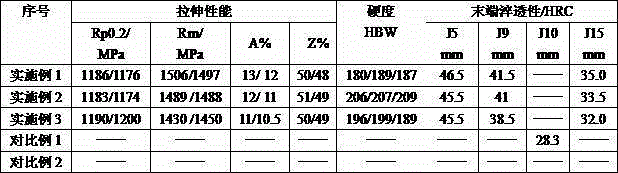

Examples

Embodiment Construction

[0020] Below in conjunction with embodiment the present invention is further described.

[0021] A nitrogen-added 20MnCr5 gear steel, its composition and weight percentage (Wt%) are: C: 0.18%~0.21%, Si: ≤0.12%, Mn: 1.25%~1.35%, Cr: 1.16%~1.24%, P: ≤0.020%, S: 0.020%~0.030%, Al: 0.025%~0.045%, N: 0.0060%~0.0100%, including the following residual components by weight percentage (Wt%): Ni: ≤0.10%, Cu : ≤0.10%, B≤0.0003%, [O]≤15×10 -6 . The remainder is Fe and some other trace residual elements.

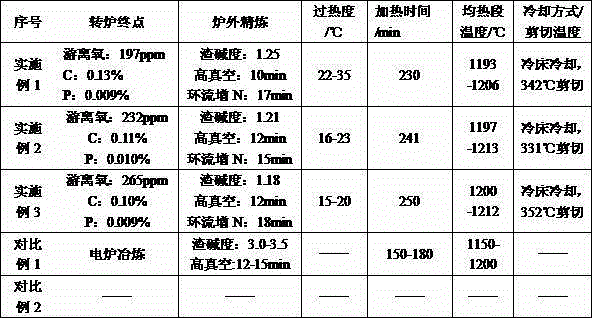

[0022] A kind of production method of nitrogen-added 20MnCr5 gear steel, its production steps are:

[0023] The first step: Converter smelting, strictly control the content of free oxygen and P in the steel at the end point, eliminate the slag after tapping, and control the free oxygen in the steel to ≤400ppm; P≤0.015%;

[0024] The second step: refining outside the furnace. After taking the first component sample, adjust the S in the steel to 0.023%~0.027% according to the detected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com