Non-heat treatment medium-strength aluminum alloy conductor material and preparation method thereof

A medium-strength aluminum alloy and aluminum alloy conductor technology, applied in the direction of metal/alloy conductors, cable/conductor manufacturing, electrical components, etc., to achieve significant economic benefits, solve continuous production bottlenecks, and save power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

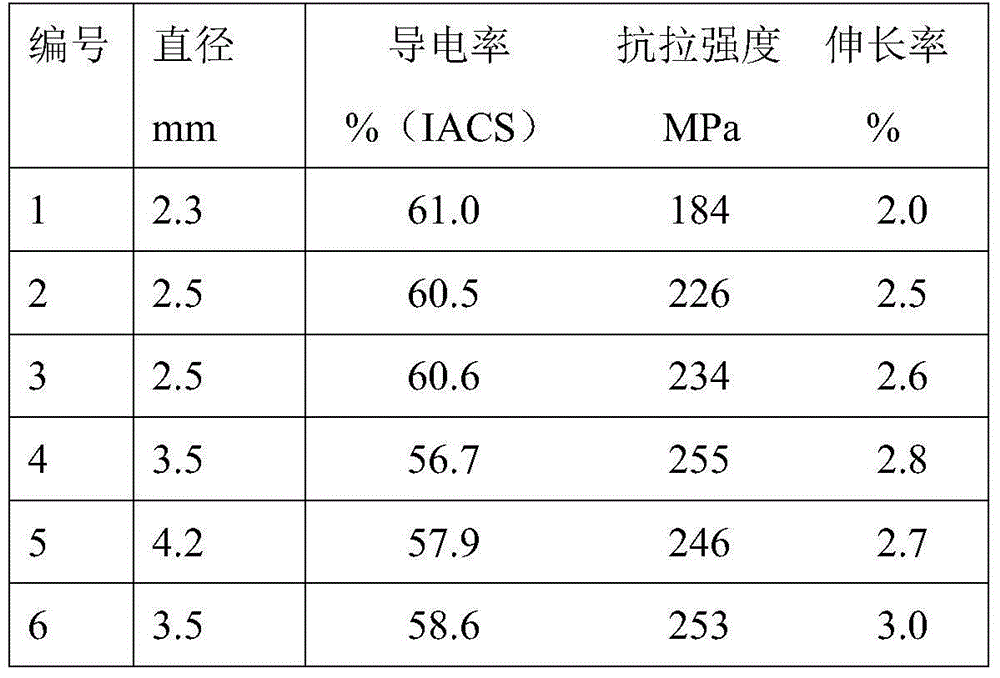

Examples

Embodiment 1

[0008] Embodiment 1: A non-heat treatment type medium-strength aluminum alloy conductor material, the conductor material is mainly composed of iron, copper, magnesium, yttrium, boron alloy elements, inevitable impurity elements, silicon, chromium, manganese, vanadium, titanium and matrix Aluminum composition. The mass percentages of alloying elements are as follows: 0.35% Fe, 0.14% Cu, 0.025% Mg, 0.02% Y, 0.001% B.

[0009] The preparation process of the above-mentioned non-heat-treated medium-strength aluminum alloy conductor material is as follows: Si≤0.11%, Fe≤0.30%, Cu≤0.05%, Mg≤0.04%, (Cr+Mn+V+Ti)≤0.015%, and the rest per The impurity content of impurity elements ≤ 0.03% requires the selection of aluminum ingots. The aluminum ingot used is Al99.70 industrial pure aluminum ingot, and its impurity content is 0.06% Si, 0.17% Fe, 0.02% Cu, 0.001% Mg, 0.009% (Cr+Mn+V+Ti). The aluminum ingot, Al-10Fe alloy, Al-50Cu alloy, Al-10Mg alloy and Al-10Y-1B alloy are weighed accordin...

Embodiment 2

[0010] Embodiment 2: A non-heat treatment type medium-strength aluminum alloy conductor material, the conductor material is mainly composed of iron, copper, magnesium, lanthanum, boron alloy elements, inevitable impurity elements, silicon, chromium, manganese, vanadium, titanium and matrix Aluminum composition. The mass percentages of alloying elements are as follows: 0.50% Fe, 0.10% Cu, 0.013% Mg, 0.03% La, 0.003% B.

[0011] The preparation process of the above-mentioned non-heat-treated medium-strength aluminum alloy conductor material is as follows: Si≤0.11%, Fe≤0.30%, Cu≤0.05%, Mg≤0.04%, (Cr+Mn+V+Ti)≤0.015%, and the rest per The impurity content of impurity elements ≤ 0.03% requires the selection of aluminum ingots. The aluminum ingot used is Al99.70 industrial pure aluminum ingot, and its impurity content is 0.08% Si, 0.18% Fe, 0.022% Cu, 0.002% Mg, 0.011% (Cr+Mn+V+Ti). The aluminum ingot is weighed according to the mass percentage of the above alloy elements, and the ...

Embodiment 3

[0012] Embodiment 3: A non-heat treatment type medium-strength aluminum alloy conductor material, the conductor material is mainly composed of iron, copper, magnesium, yttrium, boron alloy elements, inevitable impurity elements, silicon, chromium, manganese, vanadium, titanium and matrix Aluminum composition. The mass percentages of alloying elements are as follows: 0.41% Fe, 0.25% Cu, 0.03% Mg, 0.026% Y, 0.0026% B.

[0013] The preparation process of the above-mentioned non-heat-treated medium-strength aluminum alloy conductor material is as follows: Si≤0.11%, Fe≤0.30%, Cu≤0.05%, Mg≤0.04%, (Cr+Mn+V+Ti)≤0.015%, and the rest per The impurity content of impurity elements ≤ 0.03% requires the selection of aluminum ingots. The aluminum ingot used is Al99.70 industrial pure aluminum ingot, and its impurity content is 0.10% Si, 0.23% Fe, 0.02% Cu, 0.0013% Mg, 0.013% (Cr+Mn+V+Ti). The aluminum ingot, Al-6Fe alloy, Al-20Cu alloy, Al-10Mg alloy and Al-10Y-1B alloy are weighed accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com