Ti-Al-Mo-Cr series beta titanium alloy with ultralow elastic modulus and ultrahigh work hardening rate and heat treatment process thereof

A technology of ti-al-mo-cr and elastic modulus, which is applied in the field of titanium alloy processing, can solve the problems that limit the application and promotion of titanium alloys, and achieve the suppression of Ti-Cr eutectoid reaction, high work hardening rate, and good strong plasticity matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

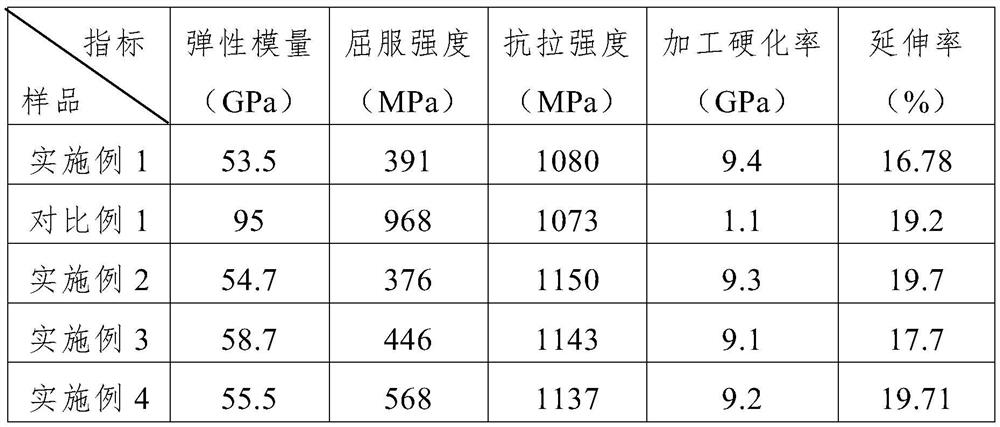

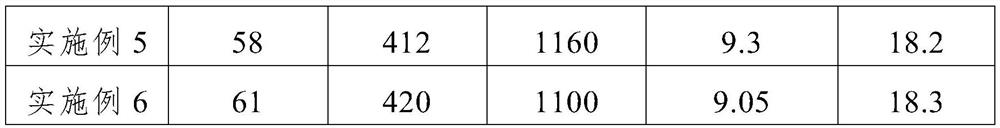

Embodiment 1

[0020] The Ti-Al-Mo-Cr series β-titanium alloy of this embodiment is composed of the following components in mass percentage: Al 4.7%, Mo 6.26%, Cr 2.85%, and the balance is Ti and unavoidable impurity elements; the Ti - Md=2.386, Bo=2.768 of the Al-Mo-Cr system β titanium alloy.

[0021] The preparation process of the Ti-Al-Mo-Cr series β-titanium alloy in this embodiment is as follows: according to the design composition of the target product, the Al-Mo master alloy is uniformly mixed with electrolytic Cr, sponge titanium, and aluminum beans, and pressed into electrodes, and then Carry out two vacuum self-consumption smelting to obtain ingots, and control the content of impurity elements in the ingots C≤0.1%, N≤0.03%, H≤0.15%, O≤0.15%; Insulate for 12 hours for high-temperature homogenization treatment, after peeling, cutting the riser and tail end, and then carry out billet forging at 1100 °C in sequence, at (T β +50℃)~(T β +100°C) to complete two-fire and three-fire forg...

Embodiment 2

[0025] The difference between this example and Example 1 is that the solution treatment temperature is 860°C.

Embodiment 3

[0027] The difference between this example and Example 1 is that the solution treatment temperature is 810°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com