TiZrVNb-based high-entropy alloy containing rare earth elements and preparation method thereof

A high-entropy alloy and rare earth element technology is applied in the field of high-entropy alloys of TiZrVNb system to achieve the effects of improving nucleation rate, refining grains and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

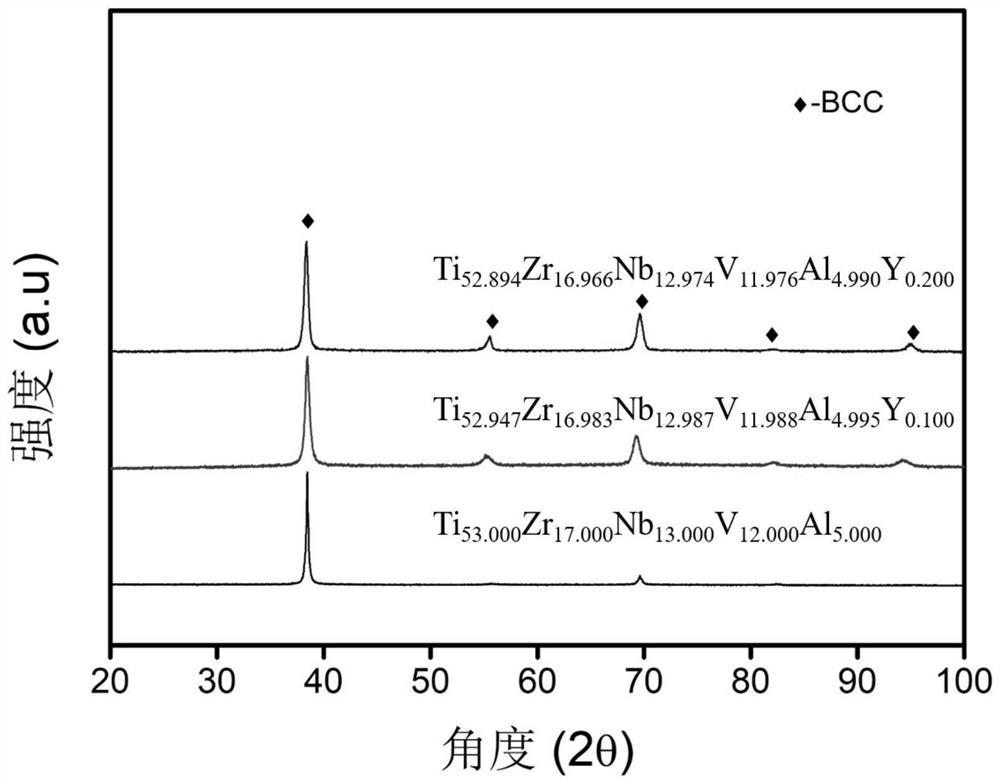

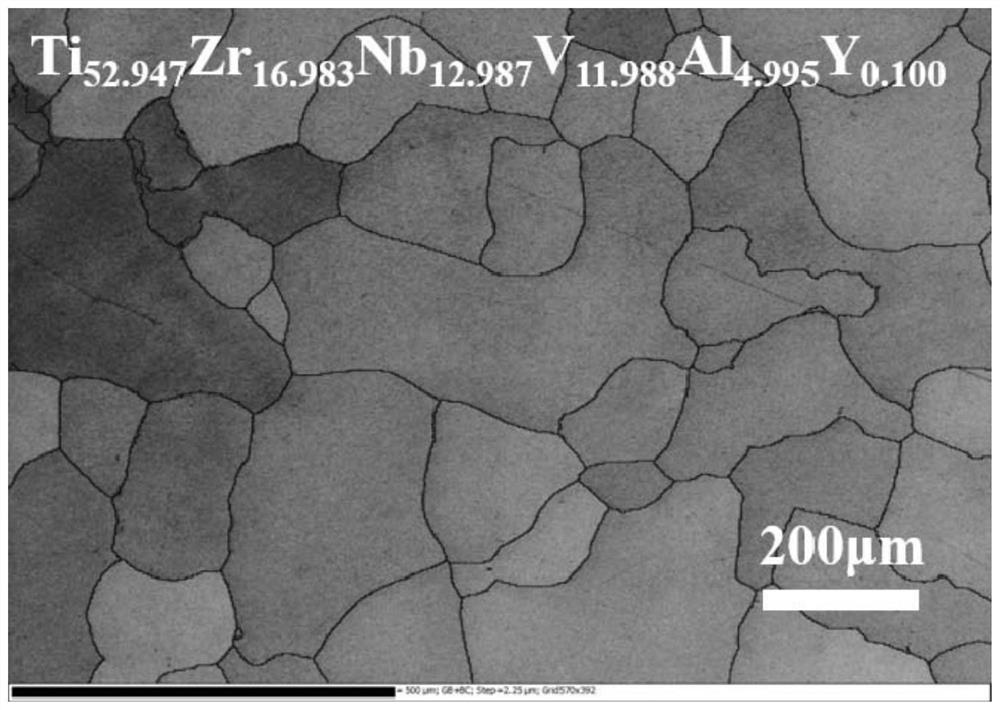

[0030] (1) Using metal elemental Ti, Zr, Al, Nb, V and Y as raw materials, first use grinding wheels to polish to remove the oxide film on the surface of the raw materials, then place them in absolute alcohol for ultrasonic vibration cleaning and drying, and then according to Ti: The atomic ratio of Zr: Nb: V: Al: Y=52.947:16.983:12.987:11.988:4.995:0.100 weighs each metal element;

[0031] (2) Put the weighed metal elemental raw material into the crucible in the induction melting furnace, and then evacuate the vacuum in the furnace to less than 5×10 -3 Pa, then fill the furnace with argon until the pressure reaches 0.05MPa, and then smelt. After the raw materials are completely melted, keep warm for 2 minutes to mix the molten alloy liquid evenly. After the heat preservation is over, turn off the power of the induction melting furnace for cooling to obtain ingots;

[0032] (3) After the ingot is turned over, repeat the smelting according to the conditions of step (2), repeat ...

Embodiment 2

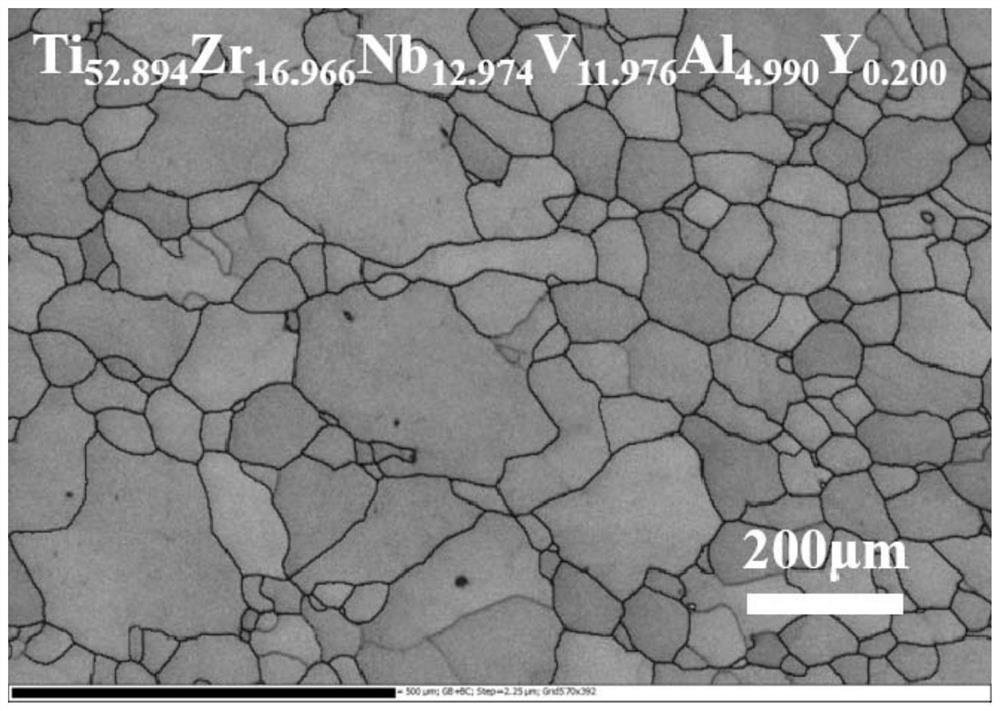

[0037] (1) Using metal elemental Ti, Zr, Al, Nb, V and Y as raw materials, first use grinding wheels to polish to remove the oxide film on the surface of the raw materials, then place them in absolute alcohol for ultrasonic vibration cleaning and drying, and then according to Ti: The atomic ratio of Zr: Nb: V: Al: Y=52.894:16.966:12.974:11.976:4.990:0.200 weighs each metal element;

[0038] (2) Put the weighed metal elemental raw material into the crucible in the induction melting furnace, and then evacuate the vacuum in the furnace to less than 5×10 -3 Pa, then fill the furnace with argon until the pressure reaches 0.05MPa, and then smelt. After the raw materials are completely melted, keep warm for 2 minutes to mix the molten alloy liquid evenly. After the heat preservation is over, turn off the power of the induction melting furnace for cooling to obtain ingots;

[0039] (3) After the ingot is turned over, repeat the smelting according to the conditions of step (2), and rep...

Embodiment 3

[0045] (1) Using metal elemental Ti, Zr, Al, Nb, V and Y as raw materials, first use grinding wheels to polish to remove the oxide film on the surface of the raw materials, then place them in absolute alcohol for ultrasonic vibration cleaning and drying, and then according to Ti: The atomic ratio of Zr: Nb: V: Al: Y=52.788:16.932:12.948:11.952:4.980:0.400 weighs each metal element;

[0046] (2) Put the weighed metal elemental raw material into the crucible in the induction melting furnace, and then evacuate the vacuum in the furnace to less than 5×10 -3 Pa, then fill the furnace with argon until the pressure reaches 0.05MPa, and then smelt. After the raw materials are completely melted, keep warm for 2 minutes to mix the molten alloy liquid evenly. After the heat preservation is over, turn off the power of the induction melting furnace for cooling to obtain ingots;

[0047] (3) After the ingot is turned over, repeat the smelting according to the conditions of step (2), and rep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com