Hot-rolled dual-phase steel in 590MPa tensile strength grade and method for manufacturing hot-rolled dual-phase steel

A technology of hot-rolled dual-phase steel and tensile strength, which is applied in the field of steel plate production, can solve the problems that the fatigue performance of parts cannot meet the design requirements, the high requirements of unfavorable part formability, and poor formability, etc., and achieve high delayed failure at room temperature , Large work hardening rate, high tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

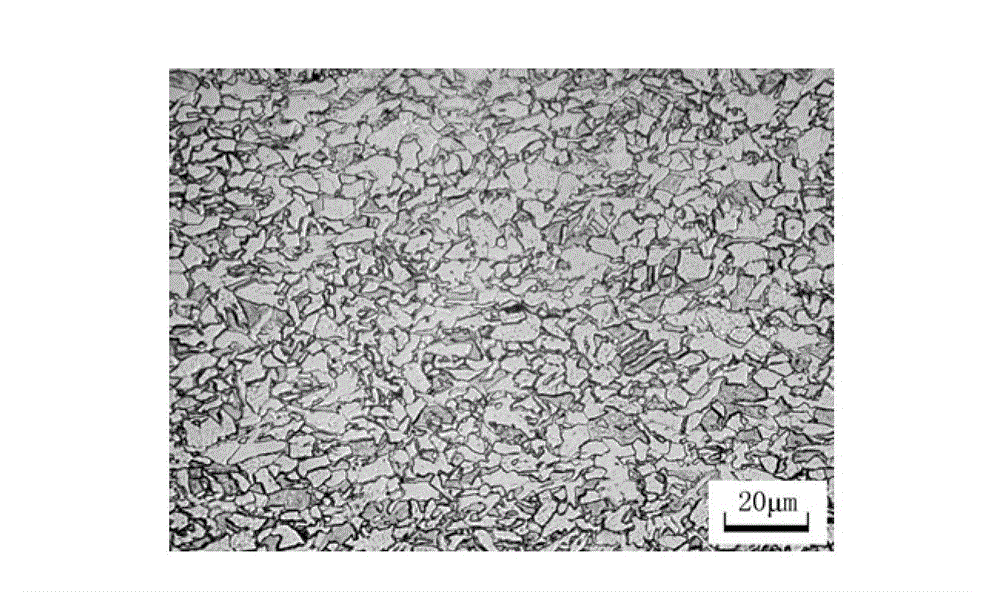

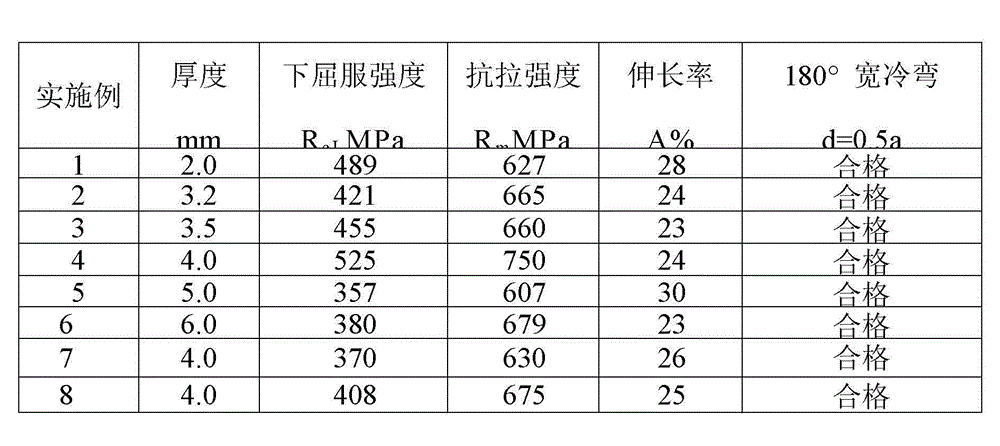

[0030] The hot-rolled dual-phase steel with a tensile strength of 590 MPa and its manufacturing method according to the present invention will be described in detail below with reference to the accompanying drawings and specific examples.

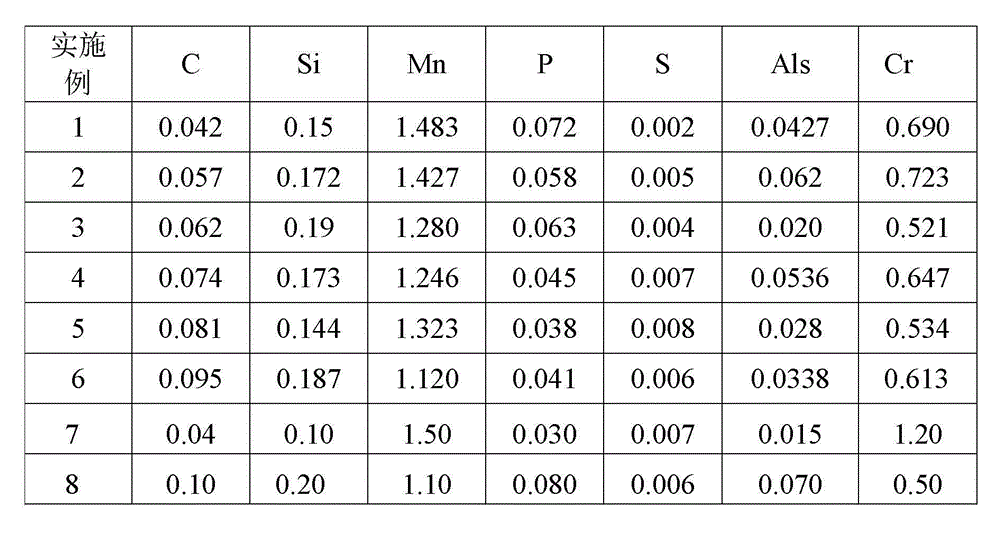

[0031] Table 1 shows the weight percentage of the chemical composition of the steel of the specific embodiment of the present invention (the balance is Fe and unavoidable impurities).

[0032] Table 1

[0033]

[0034] The manufacturing method of the above-mentioned steel is as follows: top-bottom compound blowing is carried out on the 90-ton and 250-ton converters in the steelmaking plant, and the molten iron desulfurization technology is adopted to make the S in the molten iron ≤ 0.005%; Adding ferroalloy, the addition is completed when 2 / 3 of the steel is tapped, the alloying sequence: aluminum-iron → ferromanganese → ferrophosphorus → ferrochromium, using an aluminum adding machine to add aluminum wires for final deoxidation, fine-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Lower yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com