Particle reinforced titanium-aluminum composite based on spinning deformation and preparation method thereof

A particle enhancement and spinning deformation technology, which is applied in manufacturing tools, welding equipment, welding equipment, etc., can solve the problems that the quality of explosion bonding is difficult to meet the requirements, the stress is difficult to eliminate, and the subsequent use is affected, so as to achieve the improvement of explosion composite conditions, The effect of improving plastic deformation ability and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

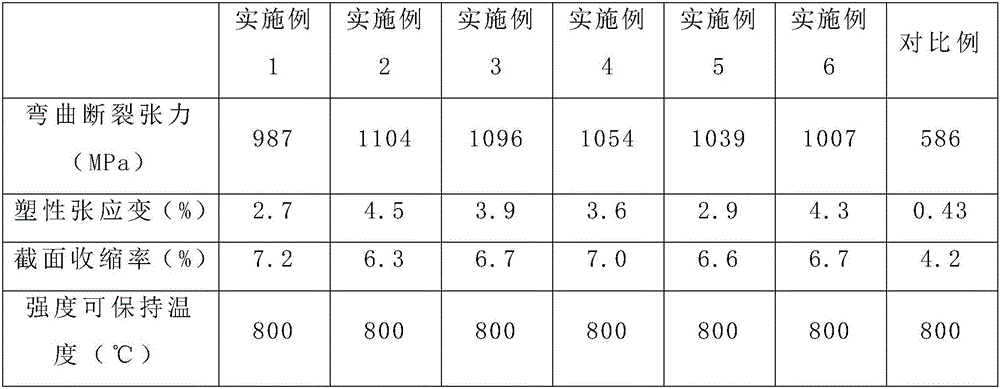

Examples

Embodiment 1

[0027] (1) The cold-rolled titanium alloy TA18 plate and aluminum alloy LY12 plate are used as the initial blanks for explosive welding. Among them, the TA18 plate is coated with 0.1mm thick pure titanium on both sides, the thickness is 0.75mm, the elongation is more than 45%, and the LY12 plate is two breads. Covered with 0.2mm thick pure aluminum, the thickness is 1.5mm, the elongation is greater than 25%, the TA18 plate is vacuum softened and annealed, the LY12 plate is annealed, the cold-rolled titanium alloy TA18 plate is mechanically polished, and the aluminum alloy LY12 is acidified Wash passivation treatment.

[0028] (2) Explosive welding of the treated TA18 and LY12 plates, the explosive welding adopts ammonium nitrate mixed explosive, and its composition is: ammonium nitrate mass percentage 60%, TNT mass percentage 3%, diesel mass percentage 1%, and the balance For sawdust, the explosive velocity is 2000m / s, the charge height is 15mm, the installation gap is 1mm, and t...

Embodiment 2

[0032] (1) The cold-rolled titanium alloy TA18 plate and aluminum alloy LY12 plate are used as the initial blanks for explosive welding. Among them, the TA18 plate is coated with 0.3mm thick pure titanium on both sides, the thickness is 1.3mm, the elongation is more than 45%, and the LY12 plate has two breads. Covered with 0.5mm thick pure aluminum, the thickness is 2.7mm, the elongation is greater than 25%, the TA18 plate is vacuum softened and annealed, the LY12 plate is annealed, the cold-rolled titanium alloy TA18 plate is mechanically polished, and the aluminum alloy LY12 is acidified Wash passivation treatment.

[0033] (2) Explosive welding of the treated TA18 and LY12 plates, the explosive welding adopts ammonium nitrate mixed explosive, and its composition is: ammonium nitrate mass percentage 80%, TNT mass percentage 10%, diesel mass percentage 10%, and the balance For sawdust, the explosive velocity is 4000m / s, the charge height is 30mm, the installation gap is 4mm, and...

Embodiment 3

[0037] (1) The cold-rolled titanium alloy TA18 plate and aluminum alloy LY12 plate are used as the initial blanks for explosive welding. Among them, the TA18 plate is coated with 0.2mm thick pure titanium on both sides, the thickness is 1.0mm, the elongation is more than 45%, and the LY12 plate has two breads Covered with 0.3mm thick pure aluminum, the thickness is 2.0mm, the elongation is greater than 25%, the TA18 plate is vacuum softened and annealed, the LY12 plate is annealed, the cold-rolled titanium alloy TA18 plate is mechanically polished, and the aluminum alloy LY12 is acidified Wash passivation treatment.

[0038] (2) Explosive welding of the processed TA18 and LY12 plates, the explosive welding adopts ammonium nitrate mixed explosive, and its composition is: ammonium nitrate mass percentage 70%, TNT mass percentage 5%, diesel mass percentage 4%, balance For sawdust, the explosive speed is 3000m / s, the charge height is 20mm, the installation gap is 2mm, and the gap sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com