Method for producing tough iron-chromium-aluminium ferritic electrothermal alloy

A technology of aluminum ferrite and electrothermal alloy, which is applied in the field of iron-chromium-aluminum ferrite electrothermal alloy, can solve the problems of coarse grains and reduction in the number of grain boundaries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The production method of ductile iron-chromium-aluminum ferritic electric heating alloy is characterized in that:

[0059] 1) Selection of raw materials:

[0060] The pure Fe and metal Cr used, the mass percentage of carbon in pure Fe is controlled below 0.02, and the oxide scale on the surface of pure iron is not treated in any way;

[0061] 2) Process:

[0062] a. Vacuum smelting: smelting pure Fe, metal Cr, Al, Mo under vacuum, without protective atmosphere, the vacuum degree during the melting period is controlled at 30Pa, the chemical composition of the ductile iron-chromium-molybdenum ferrite alloy The mass percentage is: C0.005, N0.025, Si0.1, Mn0.08, Cr31, Al6.0, P0.030, S0.030, Mo0-0.22, and the balance is Fe and unavoidable impurities;

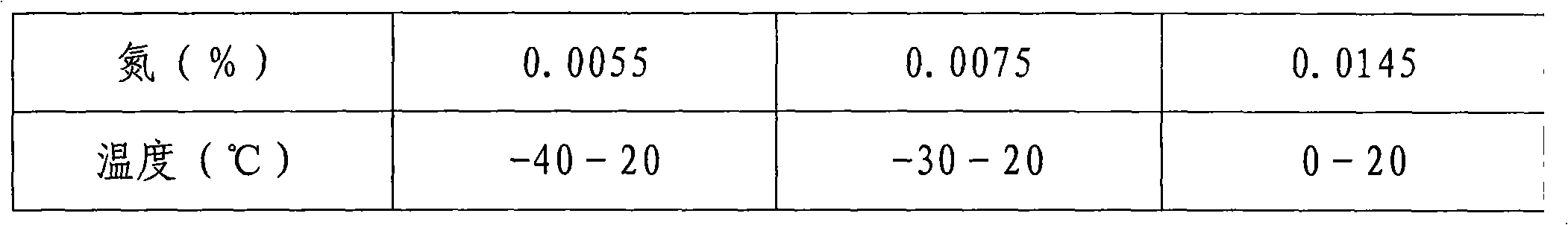

[0063] b. High-temperature vacuum refining: high-temperature, high-vacuum refining system is adopted. The molten steel is refined at 1620-1670°C and 3Pa vacuum for 15-20 minutes. When the vacuum reaches 23000Pa, oxygen blowi...

Embodiment 2

[0070] The production method of ductile iron-chromium-aluminum ferritic electric heating alloy is characterized in that:

[0071] 1) Selection of raw materials:

[0072] The pure Fe and metal Cr used, the mass percentage of carbon in pure Fe is controlled below 0.02, and the oxide scale on the surface of pure iron is not treated in any way;

[0073] 2) Process:

[0074] a. Vacuum smelting: smelting pure Fe, metal Cr, Al, Nb under vacuum, without protective atmosphere, the vacuum degree during the melting period is controlled at 35Pa, the chemical composition of the tough iron-chromium-molybdenum ferrite alloy The mass percentage is: C0.001, N0.005, Si0.1, Mn0.08, Cr31, Al6.0, P0.030, S0.030, Nb0-0.22, and the balance is Fe and unavoidable impurities;

[0075] b. High-temperature vacuum refining: high-temperature, high-vacuum refining system is adopted. The molten steel is refined at 1620-1670°C and a vacuum of 1-5Pa for 15-20 minutes. When the vacuum reaches 25000Pa, oxygen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com