A high-strength and tough hot-rolled medium manganese steel with a strength-plasticity product greater than 60gpa% and its preparation method

A high-plastic product, high-strength technology, applied in the field of high-strength and tough automotive steel, can solve the problems of application limitation, high-manganese steel smelting alloy loss, surface oxidation of rolled sheets, etc., to accelerate industrial production, increase austenite content, and realize automotive Lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The chemical composition of the steel is as follows: C: 0.40%, Mn: 6.25%, Al: 2.28%, Nb: 0.027%, Si: 0.074%, P: <0.005%, S: 0.011%, and the balance is Fe and unavoidable impurities. The above ingredients were smelted in a vacuum induction melting furnace for 40 minutes, then cold-rolled in the air to room temperature to obtain a steel ingot, heated to 1150°C for 2 hours, and forged into a 60×45mm forging billet. The final forging temperature was controlled above 900°C, and air-cooled to room temperature.

[0023] In the laboratory Hot rolling is carried out on a four-roller single-stand reversible hot rolling mill. The forging billet is heated to 1200°C and held for 1.5h. After 5 passes, it is hot-rolled into a steel plate with a thickness of 3mm. The starting rolling temperature is 1150°C and the final rolling temperature is not lower than 900°C, water cooled to 430°C and air cooled to room temperature.

[0024] The hot-rolled steel plate was annealed in the two-ph...

Embodiment 2

[0027] The chemical composition, smelting, forging, and hot-rolling processes of the steel are the same as those in Example 1, except that the annealing process in the two-phase zone is to keep the temperature at 725°C for 20 minutes, and then air-cool to room temperature.

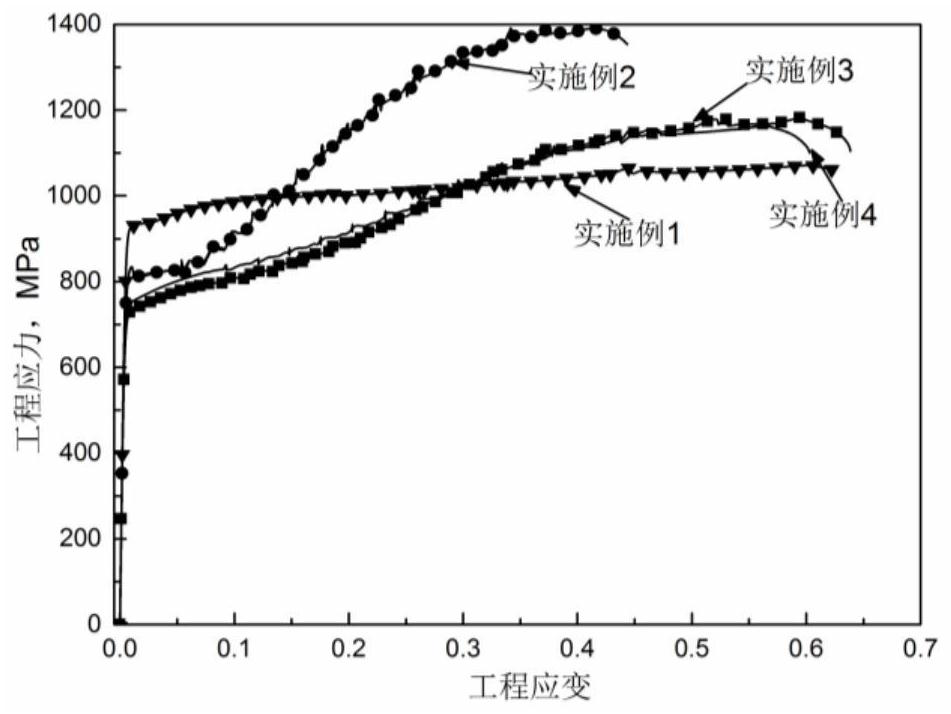

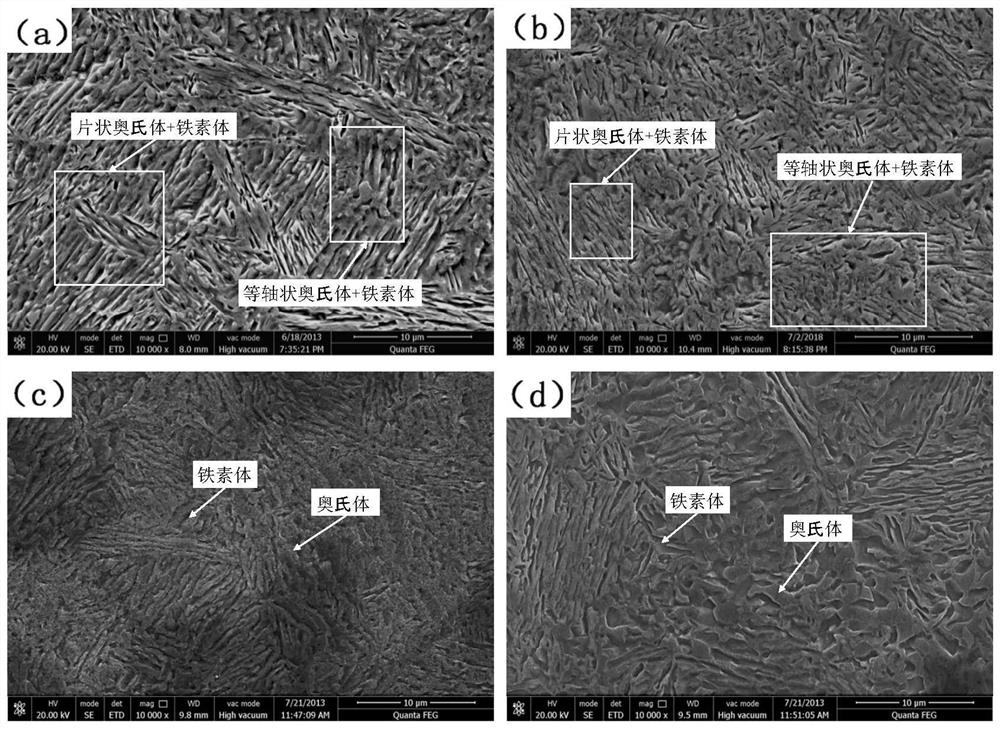

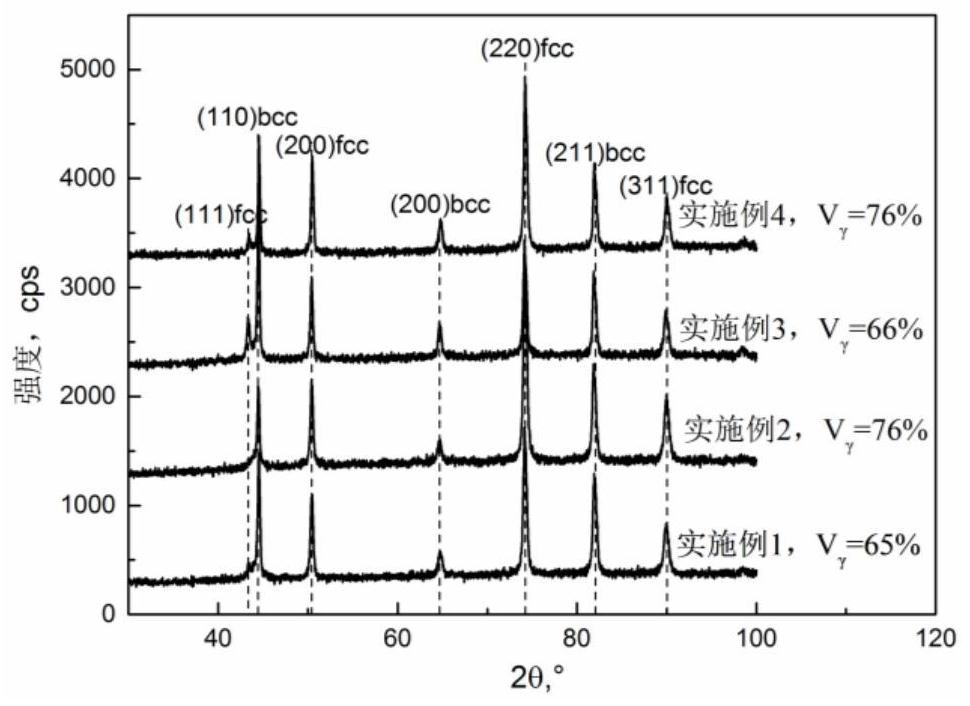

[0028] Perform related performance tests on the hot-rolled medium-manganese steel prepared in this example, and process the heat-treated steel plate into a standard tensile sample according to GB / T228-2002 "Metallic Materials Tensile Test Method at Room Temperature", and the tensile speed is fixed at 2mm / min. The results of mechanical properties are shown in Table 1, and the engineering stress-strain curve is shown in figure 1 As shown, the SEM structure morphology is as figure 2 As shown in (b), the XRD characterization results are as follows image 3 shown. It can be seen that the austenite content of the hot-rolled medium-manganese steel after annealing in the two-phase zone is 76%, the tensile str...

Embodiment 3

[0030] The chemical composition of steel is: C: 0.39%, Mn: 6.08%, Al: 2.31%, Si: 0.031%, P: <0.005%, S: 0.011%, and the balance is Fe and unavoidable impurities . The above components are smelted and cast into steel ingots in a vacuum induction furnace. The steel ingots are heated to 1150°C for 2 hours, forged into 60×45mm forging billets, and air-cooled to room temperature.

[0031] Heat the forging billet to 1200°C for 1.5h, and hot-roll it into a steel plate with a thickness of 3mm after 5 passes.

[0032]The hot-rolled steel plate was annealed in the two-phase zone in a heating furnace, kept at 700°C for 180min, and air-cooled to room temperature.

[0033] Relevant performance tests were carried out on the hot-rolled medium-manganese steel prepared in this example, and the tensile test was carried out according to GB / T228-2002 "Metal Materials Tensile Test Method at Room Temperature". The results of mechanical properties are shown in Table 1, and the engineering stress-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com