High-work-hardening-ratio hot rolling Q&P steel plate and preparing method thereof

A work-hardening and steel plate technology, which is applied in the field of high work-hardening rate hot-rolled Q&P steel plate and its preparation, can solve the problem that the process takes a long time to achieve large-scale production, the initial work-hardening rate n value is low, the strong plastic product and work-hardening rate Advanced problems, to achieve the effect of simple and feasible controlled rolling and controlled cooling process, excellent mechanical properties and formability, and grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments. These examples are only descriptions of the best implementation modes of the present invention, and do not limit the protection scope of the present invention.

[0033] A hot-rolled Q&P steel plate with a high work hardening rate and a preparation method thereof. The chemical composition of the high work hardening rate hot-rolled Q&P steel plate is: C is 0.15-0.20wt%, Si is 0.60-1.0wt%, Mn is 1.2-2.0wt%, Al is 0.03-0.06wt%, Nb is 0.03-0.06wt%, P≤0.020wt%, S≤0.005wt%, the balance is Fe and unavoidable impurities.

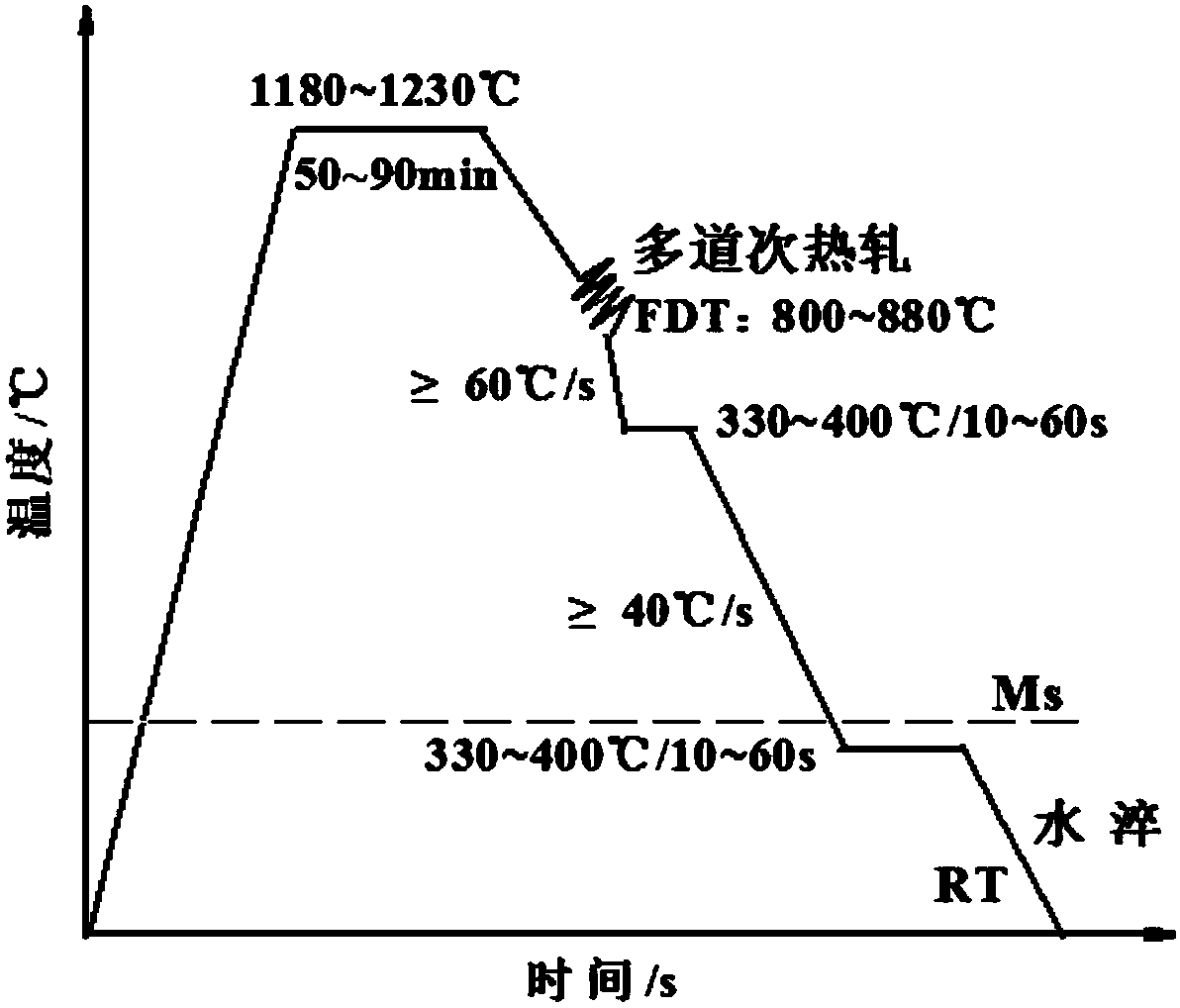

[0034] figure 1 It is a kind of process schematic diagram of this specific embodiment, from figure 1 It can be seen that the steps of the preparation method of the high work hardening rate hot-rolled Q&P steel plate are:

[0035] 1) heating

[0036] Smelting, refining, casting or continuous casting according to the chemical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com