High-strength,high-elasticity and bending-resistant copper alloy as well as preparation method and application thereof

A copper alloy, high-elastic technology, applied in the field of alloys, can solve the problems of high cost, harmful to human body, high Sn content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

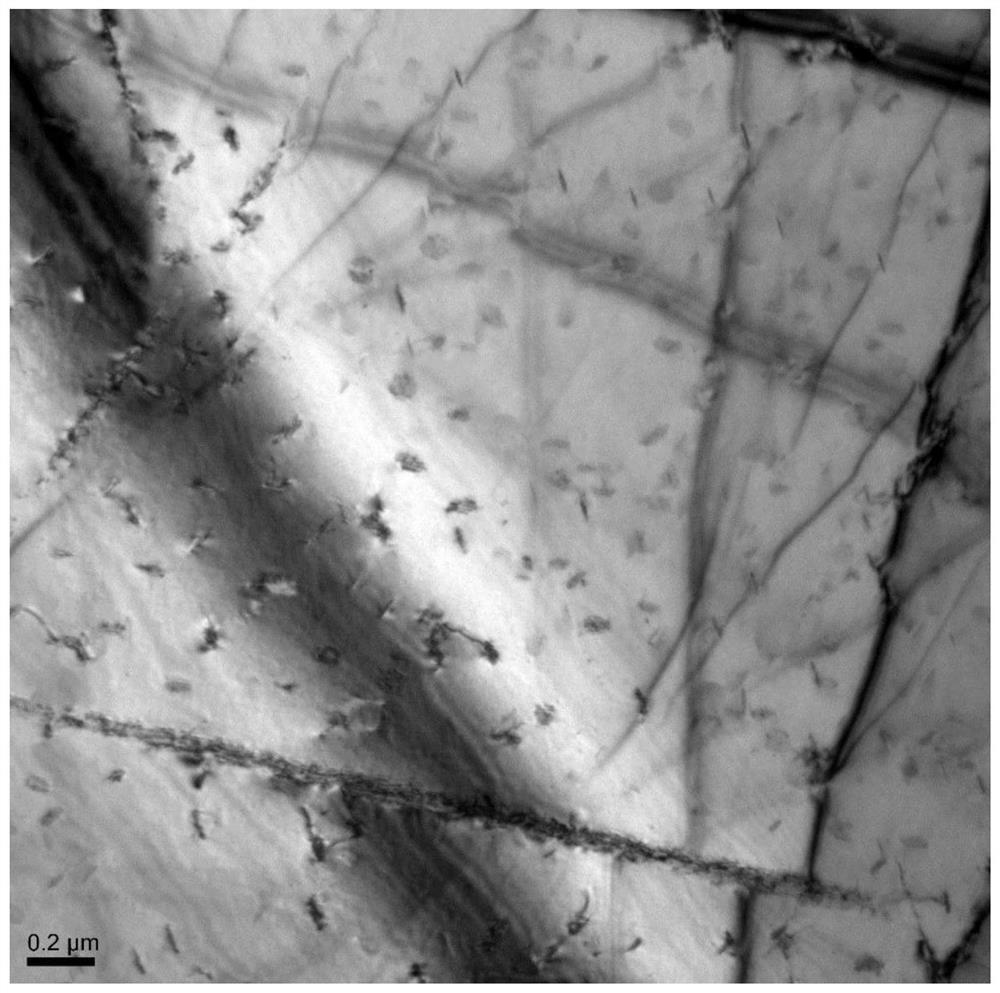

Image

Examples

preparation example Construction

[0040]The present invention also provides a method for preparing the high-strength, high-elasticity and bending-resistant copper alloy described in the above technical solution, comprising the following steps:

[0041] The alloy raw materials are smelted and drawn in turn to obtain alloy strips;

[0042] The alloy strip is sequentially subjected to preliminary rolling, intermediate rolling, first annealing, first cold finish rolling, second annealing and second cold finish rolling to obtain the high-strength, high-elasticity and bending-resistant copper alloy.

[0043] In the invention, alloy raw materials are smelted and cast in sequence to obtain alloy strips.

[0044] In the present invention, there is no special limitation on the element ratio of the alloy raw material, and the element composition of the high-strength, high-elasticity and bending-resistant copper alloy shall prevail. In the present invention, the alloy raw materials preferably include copper block, copper...

Embodiment 1

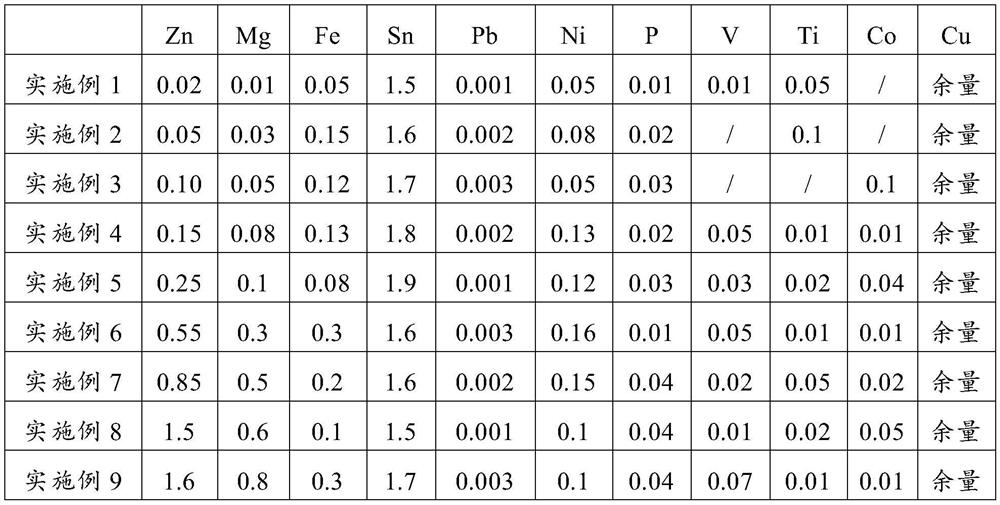

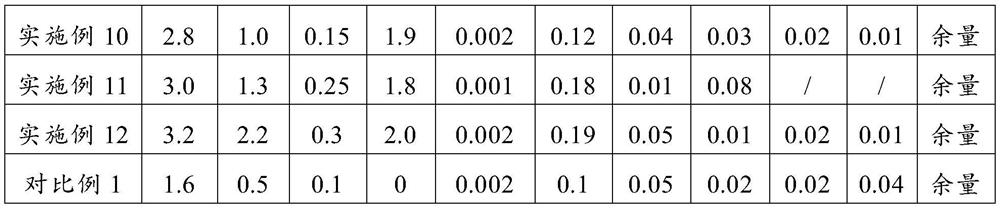

[0071] The raw material alloys are: copper block, copper foil, nickel block, iron block, phosphorus element, magnesium block, tin block, lead block, zinc block, copper-titanium master alloy (the element composition is 1.0wt.% of Ti and the balance of Cu ) and copper-vanadium master alloy (element composition is 4.0wt.% of V and the balance of Cu); the ratio of alloy elements is shown in Table 1.

[0072] Preparation method: Put the copper block in a non-vacuum induction furnace, melt it into copper liquid at 1200 ° C, add nickel block and iron block to the copper liquid, add elemental phosphorus after melting, add charcoal powder as a covering agent, and pour into the obtained smelting system Add copper foil-wrapped magnesium block, copper-titanium master alloy and copper-vanadium master alloy, add copper-foil-wrapped tin block and copper-foil-wrapped lead block before taking out the furnace, keep warm for 8 minutes and then stand at 1200°C for 7 minutes to obtain alloy melt l...

Embodiment 2

[0076] The raw material alloys are: copper block, copper foil, nickel block, iron block, phosphorus element, magnesium block, tin block, lead block, zinc block and copper-titanium master alloy (the element composition is 1.0wt.% of Ti and the balance of Cu ); see Table 1 for the ratio of alloying elements.

[0077] Preparation method: Put the copper block in a non-vacuum induction furnace, melt it into copper liquid at 1210 ° C, add nickel block and iron block to the copper liquid, add elemental phosphorus after melting, add charcoal powder as a covering agent, and pour into the obtained smelting system Add copper-foil-wrapped magnesium block and copper-titanium intermediate alloy, add copper-foil-wrapped tin block and copper-foil-wrapped lead block before leaving the furnace, heat for 8 minutes and then stand at 1205°C for 8 minutes to obtain alloy melt;

[0078] After the alloy melt is obtained, the obtained alloy melt is drawn and cast at 1160° C., and the temperature of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com