Heat treatment method for improving defects in additive manufacturing of beta-type titanium alloy

A heat treatment method and additive manufacturing technology, applied in the field of additive manufacturing, can solve the problems of complex process, accumulation of process processes, increase of manufacturing cycle and cost, etc., to achieve the effect of simple process flow, improved strength, and reduced anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

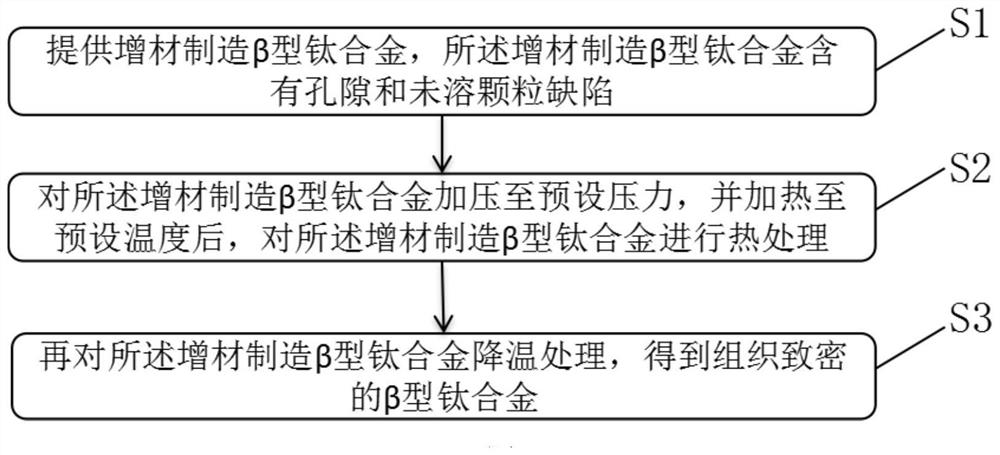

Method used

Image

Examples

Embodiment 1

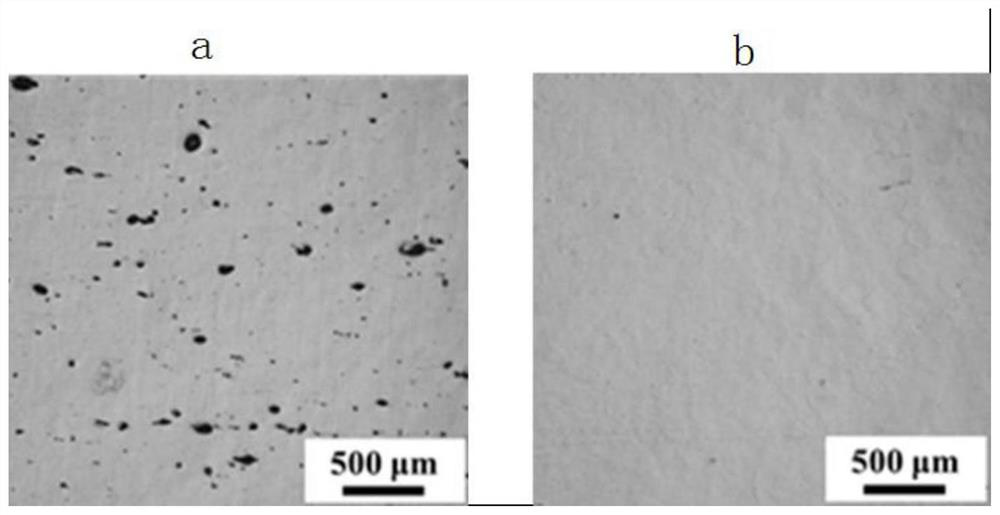

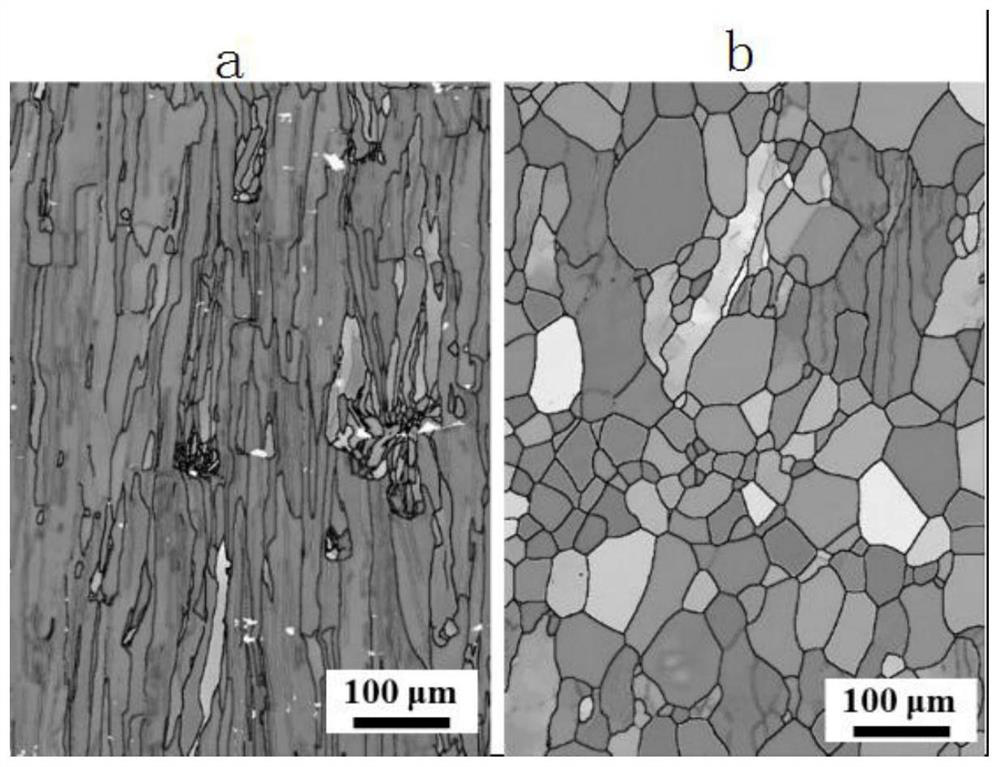

[0048] This embodiment provides a heat treatment method for improving defects in additively manufactured β-type titanium alloys. The Ti-41Nb alloy used in this embodiment is obtained through a selective laser melting process. The specific parameters for processing the Ti-41Nb alloy are: using TruPrint1000 instrument , power 120W, scanning speed 900mm / s, scanning distance 80 microns, layer thickness 20 microns. The microstructure analysis of Ti-41Nb alloy found that it contains obvious defects such as undissolved particles and pores, and the original structure has a large number of {001} oriented columnar grains parallel to the construction direction.

[0049] The melting point of Ti-41Nb alloy under normal pressure is about 1800°C. The Ti-41Nb alloy is pressurized at 4GPa with a six-sided top press and heated to 1000°C. A β-type titanium alloy with dense and significantly improved compressive yield strength.

[0050] refer to figure 2 , image 3 as shown, figure 2 It is ...

Embodiment 2

[0054] This embodiment provides a heat treatment method for improving defects in additively manufactured β-type Ti-15Mo alloys. The Ti-15Mo alloy used in this embodiment is obtained through a selective laser melting process. The specific parameters for processing the Ti-15Mo alloy are: TruPrint1000 instrument, power 130W, scanning speed 900mm / s, scanning distance 80 microns, layer thickness 20 microns. The support structure was added during the construction process, and the thermal accumulation effect was strengthened. The microstructure analysis found that it contained obvious defects such as undissolved and pores, and there were a large number of {001}-oriented columnar crystals parallel to the construction direction in the original structure.

[0055] The melting point of the Ti-15Mo alloy under normal pressure is about 1800°C. The Ti-15Mo alloy is pressurized at 6GPa with a six-sided top press and heated to 900°C. Ti-Mo alloy with dense and significantly improved compressi...

Embodiment 3

[0058] This example provides a heat treatment method for improving the anisotropy in additively manufactured β-type Ti-36Nb-2Ta-3Zr-0.3O alloy. The Ti-36Nb-2Ta-3Zr-0.3O alloy used in this example passes through the selection Obtained by laser melting process, the specific parameters for processing Ti-36Nb-2Ta-3Zr-0.3O alloy are: using TruPrint1000 instrument, power 170W, scanning speed 300mm / s, scanning distance 80 microns, layer thickness 20 microns. The support structure was added during the construction process, and the thermal accumulation effect was strengthened. The microstructure analysis found that it contained obvious defects such as pores, and there were a large number of {001}-oriented columnar crystals parallel to the construction direction in the original structure.

[0059] The Ti-36Nb-2Ta-3Zr-0.3O alloy was pressurized at 6GPa with a six-sided top press and heated to 1500°C. After holding the pressure for 20 minutes, it was cooled by water to obtain a compact str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com