Heat-resistant soluble magnesium alloy and preparation method and application thereof

A technology of magnesium alloy and master alloy, which is applied in earthwork drilling, wellbore/well components, sealing/isolation, etc. It can solve the problems of not being able to obtain good high-temperature mechanical properties and soluble properties at the same time, and not having soluble properties. , to achieve the effects of improving high temperature strength and creep resistance, refining grains, and increasing elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

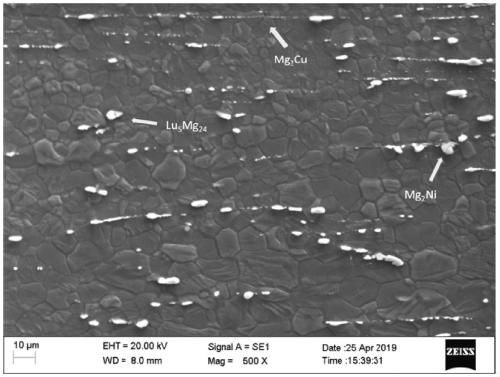

[0064] The heat-resistant soluble magnesium alloy described in this embodiment is a high-elongation slow-dissolving material, and the following atomic percentages are composed of elements: Lu 0.40%, Ce 0.04%, Al 0.20%, Ca 0.01%, Cu 0.10%, Ni 0.05 %, impurity elements <0.30%, and the rest is Mg.

[0065] The preparation method of the heat-resistant dissolvable alloy described in this embodiment is specifically as follows:

[0066] (1) Weigh the raw materials according to the above ratio. The above raw materials are pure magnesium ingots, pure aluminum ingots, Mg-Lu master alloys, Mg-Ce master alloys, Mg-Ca master alloys, Mg-Cu master alloys, and Mg-Ni master alloys. alloy;

[0067] (2) in CO 2 and SF 6 Under the protection of a mixed gas with a volume ratio of 200:1, melt at 720°C, hold for 60 minutes, stir for 10 minutes, and refine for 20 minutes. After refining, heat up to 780°C, stand for 40 minutes, and cast at 680°C to form a semi-continuous ingot;

[0068] (3) Take t...

Embodiment 2

[0073] The heat-resistant soluble magnesium alloy described in this embodiment is a high-elongation slow-dissolving material, and the following atomic percentages are composed of elements: Lu 0.10%, Ce 0.001%, Al 0.10%, Ca 0.001%, Cu 0.01%, Ni 0.01 %, impurity elements <0.30%, and the rest is Mg.

[0074] The preparation method of the heat-resistant dissolvable alloy described in this embodiment is specifically as follows:

[0075] (1) Weigh the raw materials according to the above ratio. The above raw materials are pure magnesium ingots, pure aluminum ingots, Mg-Lu master alloys, Mg-Ce master alloys, Mg-Ca master alloys, Mg-Cu master alloys, and Mg-Ni master alloys. alloy;

[0076] (2) in CO 2 and SF 6 Under the protection of a mixed gas with a volume ratio of 200:1, melt at 720°C, hold for 50 minutes, stir for 10 minutes, and refine for 30 minutes. After refining, heat up to 780°C, stand for 30 minutes, and cast at 680°C to form a semi-continuous ingot;

[0077] (3) Take t...

Embodiment 3

[0081] The heat-resistant soluble magnesium alloy described in this embodiment is a high-strength and fast-dissolving material, and the following atomic percentages are composed of elements: Lu 8.00%, Ce 0.05%, Al 0.60%, Ca 0.50%, Cu 1.00%, Ni 1.00%, Impurity elements <0.30%, the rest is Mg.

[0082] The preparation method of the heat-resistant dissolvable alloy described in this embodiment is specifically as follows:

[0083] (1) Weigh the raw materials according to the above ratio. The above raw materials are pure magnesium ingots, pure aluminum ingots, Mg-Lu master alloys, Mg-Ce master alloys, Mg-Ca master alloys, Mg-Cu master alloys, and Mg-Ni master alloys. alloy;

[0084] (2) in CO 2 and SF 6 Under the protection of a mixed gas with a volume ratio of 400:1, melt at 760°C, hold for 60 minutes, stir for 20 minutes, and refine for 20 minutes. After refining, heat up to 800°C, stand for 30 minutes, and cast at 700°C to form a semi-continuous ingot;

[0085] (3) Take the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com