High-plasticity magnesium alloy and preparation method thereof

A magnesium alloy, high plasticity technology, applied in the direction of manufacturing tools, heat treatment equipment, metal extrusion dies, etc., can solve the problems that are difficult to meet industrial applications, the strength of magnesium-lithium alloys decreases, etc., to achieve industrial applications, easy access, and process flow simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

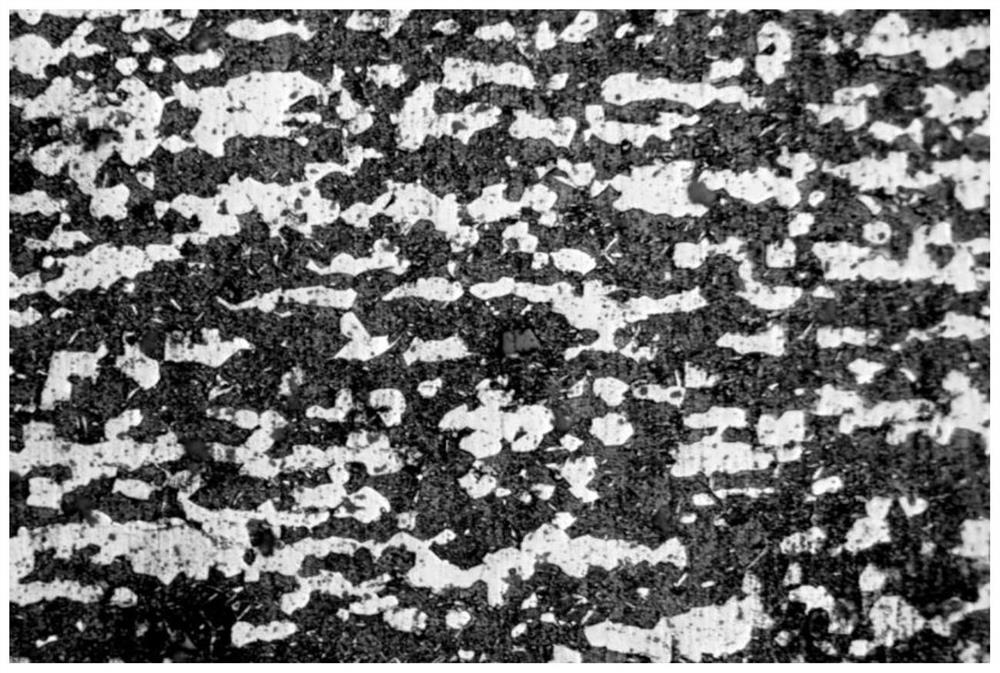

Image

Examples

preparation example Construction

[0040] In the preparation method of the present invention, wherein step C), the conditions of extrusion molding are: extrusion ratio of 28:1, extrusion speed of 1-3m / min; extrusion temperature of 200-300 °C to ensure good plasticity; if the extrusion temperature is lower than 200 °C, the extrusion ratio is less than 28, the extrusion speed is less than 1m / mi n, there will be thermal extrusion deformation difficulties, the sample surface burrs increase; if the extrusion temperature is higher than 300 °C, the extrusion ratio is higher than 28, the extrusion speed is higher than 3m / min, The sample will appear blackened, overburned, and reduced mechanical properties.

[0041] The proportion of the elements in the alloy in this application and the individual process technical parameters in the preparation method are discovered by experimentation and are optimal, because they allow you to obtain the claimed comprehensive technical results. Violation of element ratio, alloy properties de...

Embodiment 1

[0043] A highly plastic magnesium alloy, in terms of mass fraction, its chemical element composition includes: Gd 2.0%, Li 8%, the rest are Mg and unavoidable impurities, the total content of impurities is less than or equal to 0.3%.

[0044] The present invention further provides a method for preparing a highly plastic magnesium alloy, comprising the following steps:

[0045] 1) Pretreatment: surface grinding of industrial pure magnesium ingots, magnesium-lithium intermediate alloys and magnesium gadolinium intermediate alloys, remove the oxide layer on the surface, and place them in turn after industrial alcohol, and place them in an ultrasonic cleaner for cleaning;

[0046] 2) CO in volume ratio of 99:1 2 and SF 6Under the protection of the mixed gas, the pretreated pure magnesium ingot and magnesium gadolinium intermediate alloy are placed in the proportion of the above mass fraction into the crucible and placed in a resistance furnace, heated to 750 ° C, until completely mel...

Embodiment 2

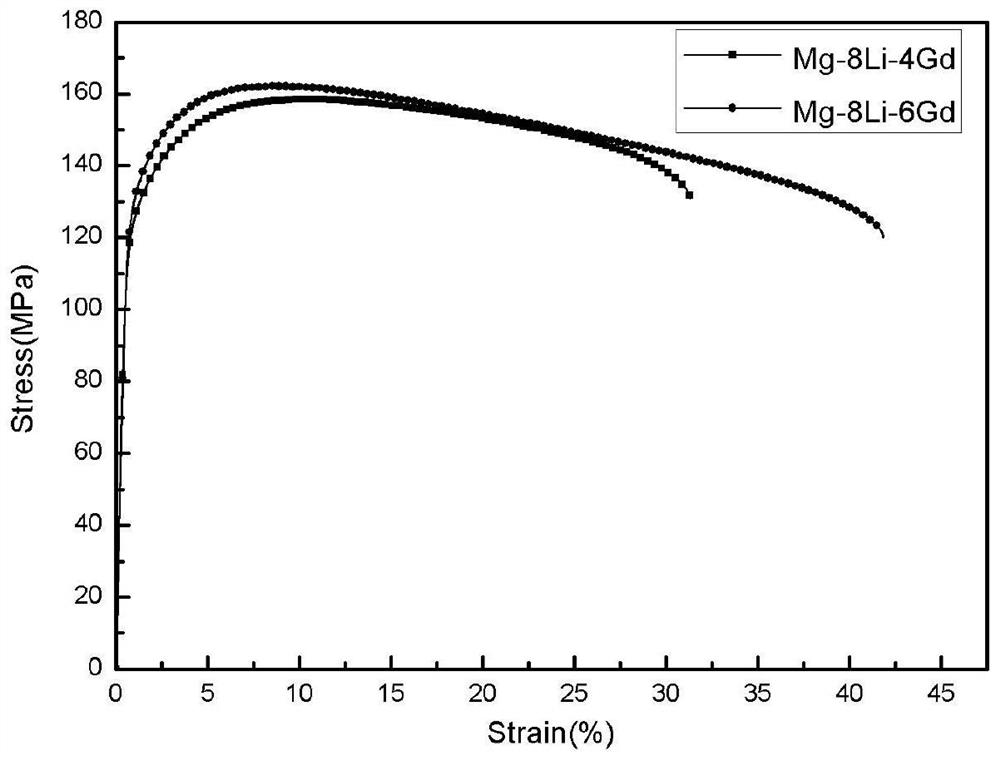

[0051] A highly plastic magnesium alloy, in terms of mass fraction, its chemical element composition includes: Gd 4.0%, Li 8%, the rest are Mg and unavoidable impurities, and the total impurity content is less than or equal to 0.3%.

[0052] The present invention further provides a method for preparing a highly plastic magnesium alloy, comprising the following steps:

[0053] 1) Pretreatment: surface grinding of industrial pure magnesium ingots, magnesium-lithium intermediate alloys and magnesium gadolinium intermediate alloys, remove the oxide layer on the surface, and place them in turn after industrial alcohol, and place them in an ultrasonic cleaner for cleaning;

[0054] 2) CO in volume ratio of 99:1 2 and SF 6 Under the protection of the mixed gas, the pretreated pure magnesium ingot and magnesium gadolinium intermediate alloy are placed in the proportion of the above mass fraction into the crucible and placed in a resistance furnace, heated to 750 ° C, until completely melt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com