A method of preparing high-strength and toughness magnesium alloy wire by baking

A magnesium alloy and wire technology, which is applied in the field of preparing magnesium alloy wire with high strength, high yield ratio and high toughness, can solve the problem that the safety and reliability of engineering applications cannot be guaranteed, the yield ratio and toughness cannot be effectively improved, and the increase Production costs and other issues, to achieve good application prospects, conducive to environmental protection, the effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

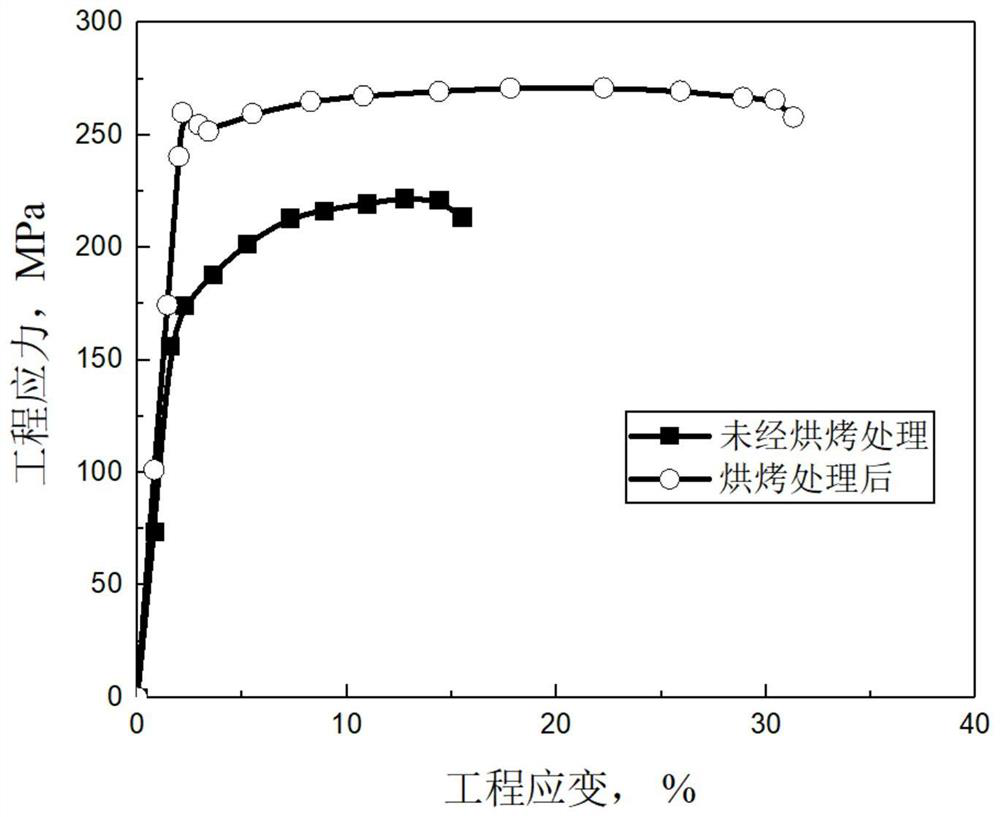

[0021] In this embodiment, the raw material is Mg-0.4Ca-0.03Y (atomic percentage), and a cylindrical magnesium alloy ingot with a diameter of 3 mm is cast by semi-continuous casting. After solution treatment, several times of drawing are carried out at room temperature. The processing rate of each pass does not exceed 15%, and the intermediate annealing and water quenching are carried out at 420°C for 60 minutes after each drawing. After the last pass, a wire rod with a diameter of 1 mm was obtained, which was baked at 200° C. for 30 minutes and quenched in water. As a comparison, another sample was still annealed at 420°C for 60 minutes after the same casting and drawing process without baking. Subsequently, the mechanical properties of the two samples were tested at room temperature. Test results such as figure 1 shown.

[0022] Comparing the engineering stress-engineering strain curves between the two shows that the yield strength and elongation of the alloy without baki...

Embodiment 2

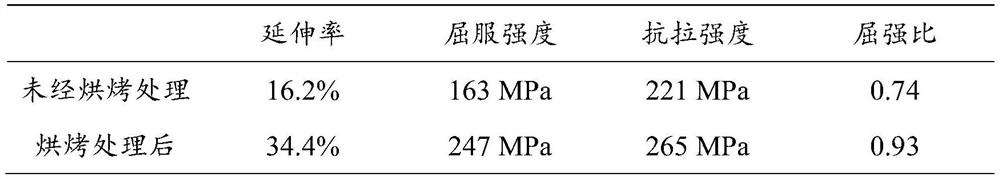

[0024] In this example, the raw material is Mg-0.6Zn-0.04Y (atomic percentage), and the semi-continuous casting method is used to cast a cylindrical magnesium alloy ingot with a diameter of 4.2 mm. After solution treatment, several times of drawing are carried out at room temperature. , the processing rate of each pass is not more than 15%, and the intermediate annealing and water quenching are carried out at 390 ° C for 100 minutes after each drawing. After the last pass, a wire rod with a diameter of 1.5 mm was obtained, which was baked at 190° C. for 40 minutes and quenched in water. As a comparison, another sample was still annealed at 390°C for 100 minutes after the same casting and drawing process without baking. Subsequently, the mechanical properties of the two samples were tested at room temperature. The test results are shown in Table 1.

[0025] Table 1

[0026]

[0027] Comparing the mechanical properties between the two, it can be seen that the yield strengt...

Embodiment 3

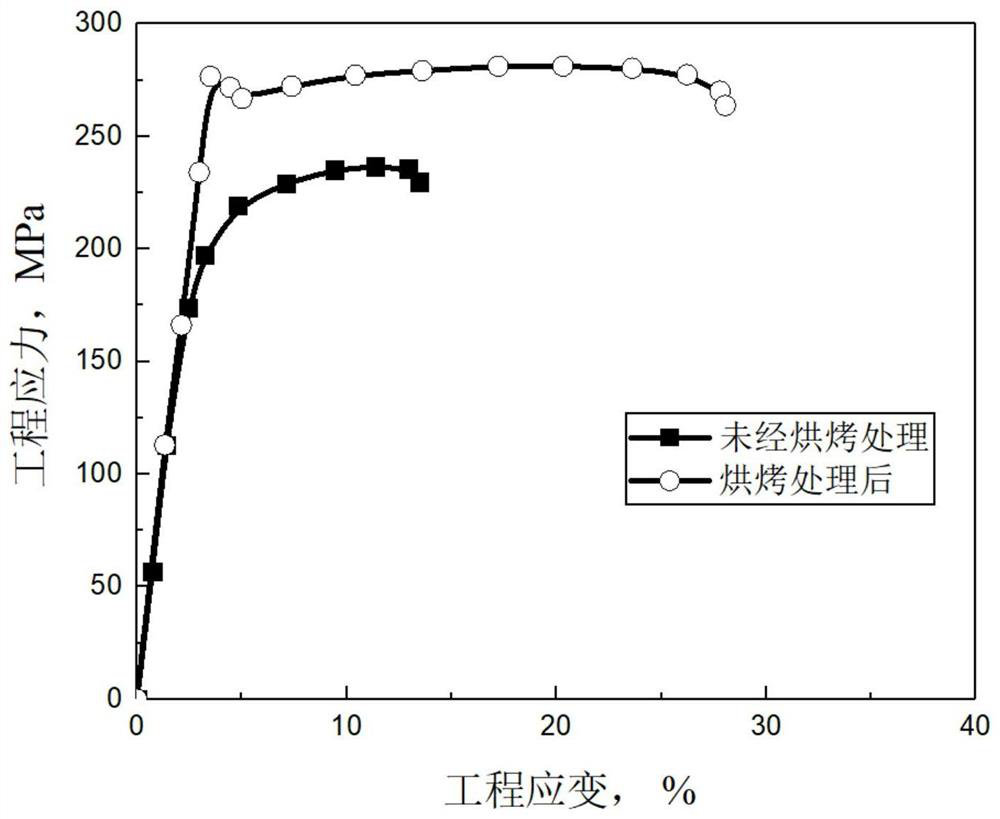

[0029] In this example, the raw material is Mg-0.9Sn-0.15Y (atomic percentage), and the semi-continuous casting method is used to cast a cylindrical magnesium alloy ingot with a diameter of 4.5 mm. After solution treatment, several times of drawing are carried out at room temperature. , The processing rate of each pass is not more than 15%, and the intermediate annealing and water quenching are carried out at 440°C for 100min after each drawing. After the last pass, a wire rod with a diameter of 1.6 mm was obtained, which was baked at 150° C. for 100 min and quenched in water. As a comparison, another sample was still annealed at 440°C for 100 minutes after the same casting and drawing process without baking. Subsequently, the mechanical properties of the two samples were tested at room temperature. The test results are shown in Table 2.

[0030] Table 2

[0031]

[0032] Comparing the mechanical properties between the two, it can be seen that the yield strength and elon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com