A light alloy rolling composite forming process with controllable edge cracking

A forming process and rolling composite technology, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of difficult industrial application, uneven surface of the plate, complex lining plate, etc., to achieve complex stress on the plate, weaving The effect of weakening the structure and uniform force on the plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

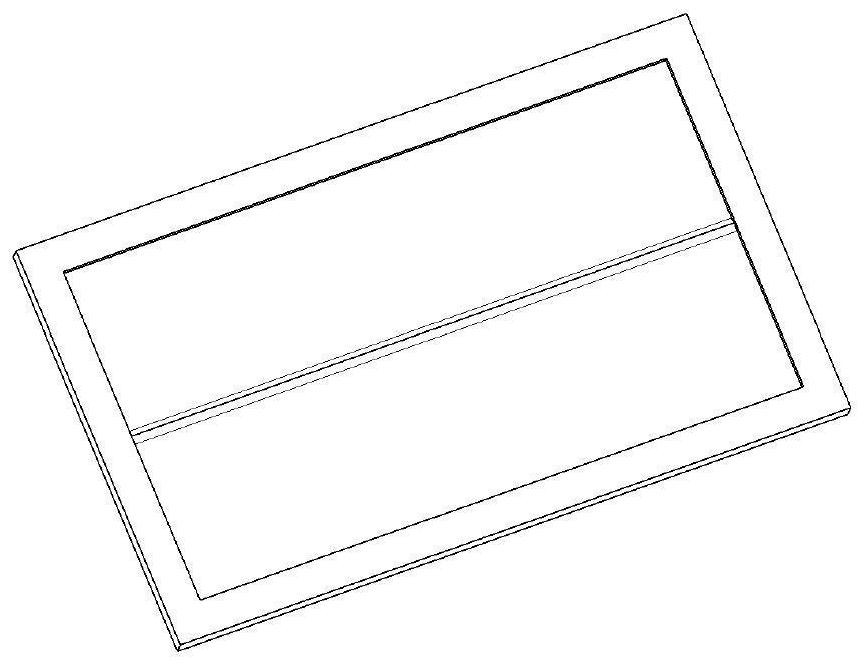

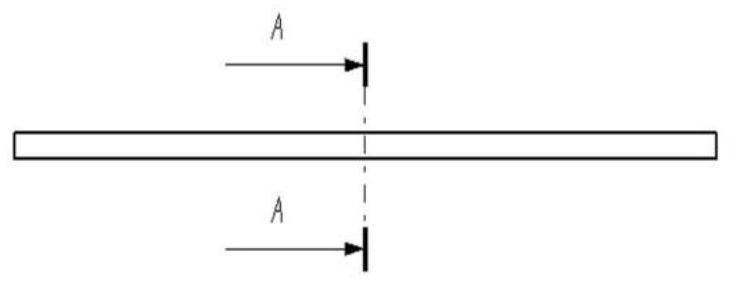

Image

Examples

Embodiment 1

[0038] (1) Select a cemented carbide liner with a groove and a wedge-shaped protrusion with a height of 3 mm, where the height of the groove is 1 mm;

[0039] (2) Select a piece of magnesium alloy extruded plate whose composition is Mg-2Al-0.8Sn (wt.%), thickness is 5 mm, and upper and lower surfaces are smooth;

[0040] (3) Spread the high-temperature lubricant evenly on the surface of the liner and the magnesium alloy, and put the extruded magnesium alloy plate and the liner into a mobile heating box with a temperature of 300 degrees Celsius for heating;

[0041] (4) leave it to stand for 10 minutes;

[0042] (5) The liner is placed on the lower surface of the magnesium alloy plate, and the liner and the Mg-2Al-0.8Sn extruded plate are simultaneously pushed to the roll inlet;

[0043] (6) Repeat (3)-(5). During the deformation process, the lining board and the magnesium alloy plate are not turned over, and the deformation is completed in four passes, and the reduction in ea...

Embodiment 2

[0046] (1) Select a cemented carbide liner with a groove and a wedge-shaped protrusion with a height of 3 mm, where the height of the groove is 1 mm;

[0047] (2) Select a piece of Mg-3Al-1Zn (wt.%) sub-rapid casting plate whose thickness is 4 millimeters and whose upper and lower surfaces are smooth;

[0048] (3) Apply the high-temperature lubricant evenly to the surface of the liner and the magnesium alloy, and put the magnesium alloy plate and the liner into a mobile heating box with a temperature of 400 degrees Celsius for heating;

[0049](4) leave it to stand for 10 minutes;

[0050] (5) The liner is placed on the lower surface of the magnesium alloy plate, and the liner and the magnesium alloy are simultaneously pushed to the rolls for single-pass rolling with a reduction of 75%.

[0051] After forming, the average grain size of the plate is 3.5μm, the yield strength is 221MPa, the tensile strength is 278MPa, and the elongation at break is 22.4%.

Embodiment 3

[0053] (1) Select a cemented carbide liner with a groove and a wedge-shaped protrusion with a height of 5 mm, where the height of the groove is 2 mm;

[0054] (2) Select a 6022 aluminum alloy cast-rolled plate with a thickness of 5 mm and smooth upper and lower surfaces;

[0055] (3) Apply the high-temperature lubricant evenly to the surface of the liner and the aluminum alloy, and place the liner on the lower surface of the aluminum alloy sheet;

[0056] (4) Push the liner plate and the aluminum alloy to the rolls simultaneously for single-pass cold rolling with a reduction of 60%.

[0057] The formed plate was subjected to T4 heat treatment, and the average grain size of the formed plate was 32.7 μm, the yield strength was 120 MPa, the tensile strength was 263 MPa, and the elongation at break was 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com