High-plasticity rapidly-degradable Mg-Li-Gd-Ni alloy and preparation method thereof

A rapid degradation and high plasticity technology, applied in the field of metal material processing, can solve the problems of complex magnesium alloy composition, high production cost, poor elongation, etc., and achieve the effect of easy operation and regulation, easy acquisition, and reduced production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

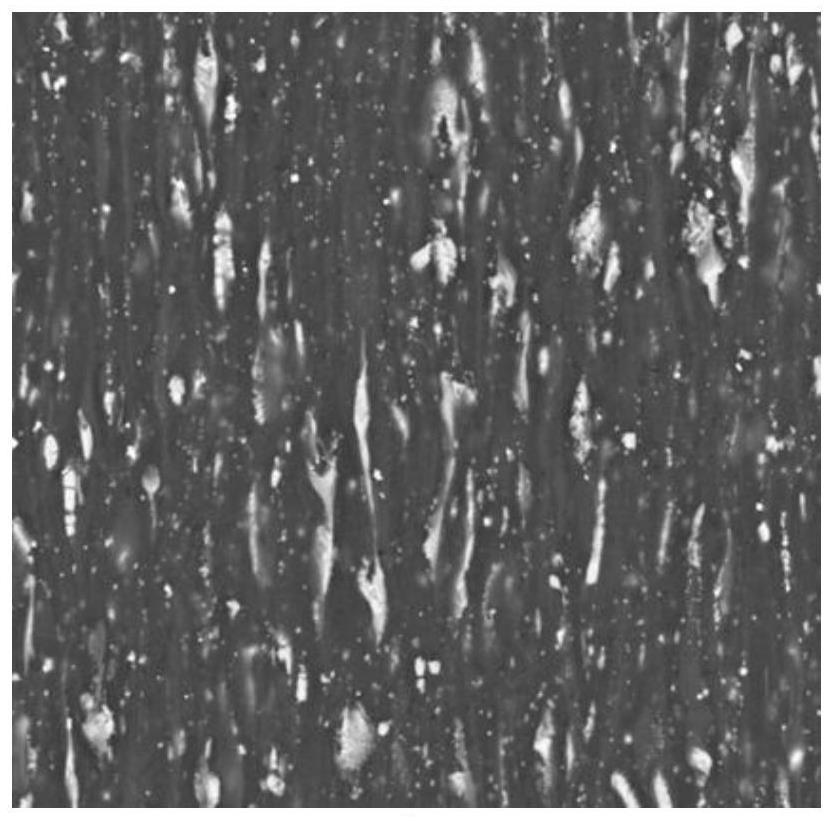

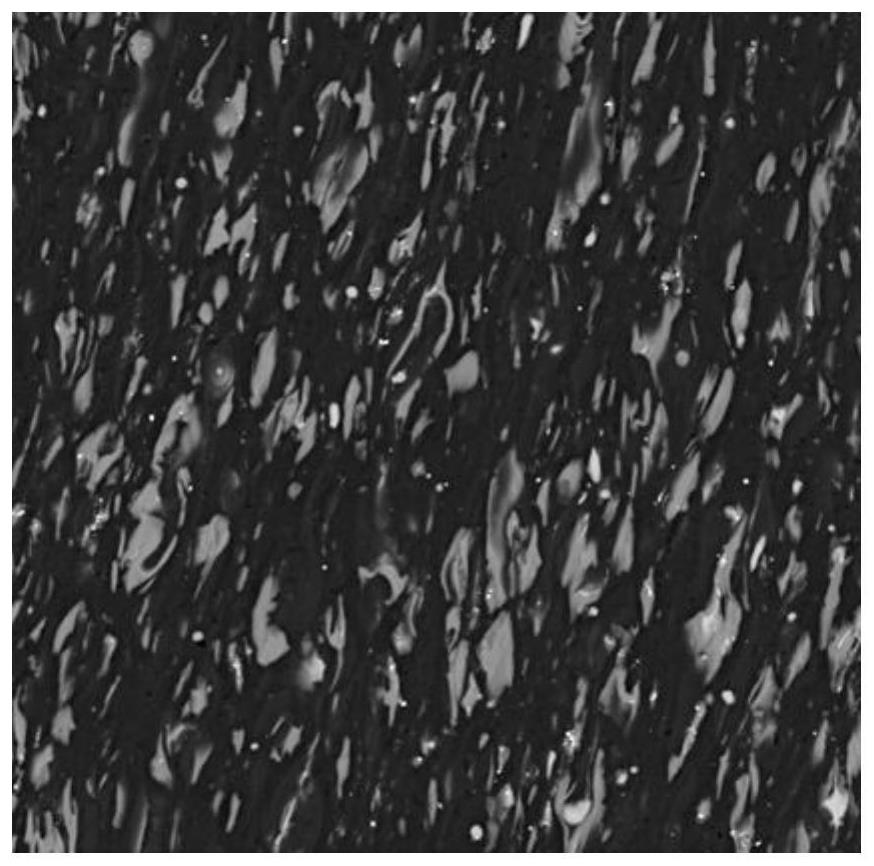

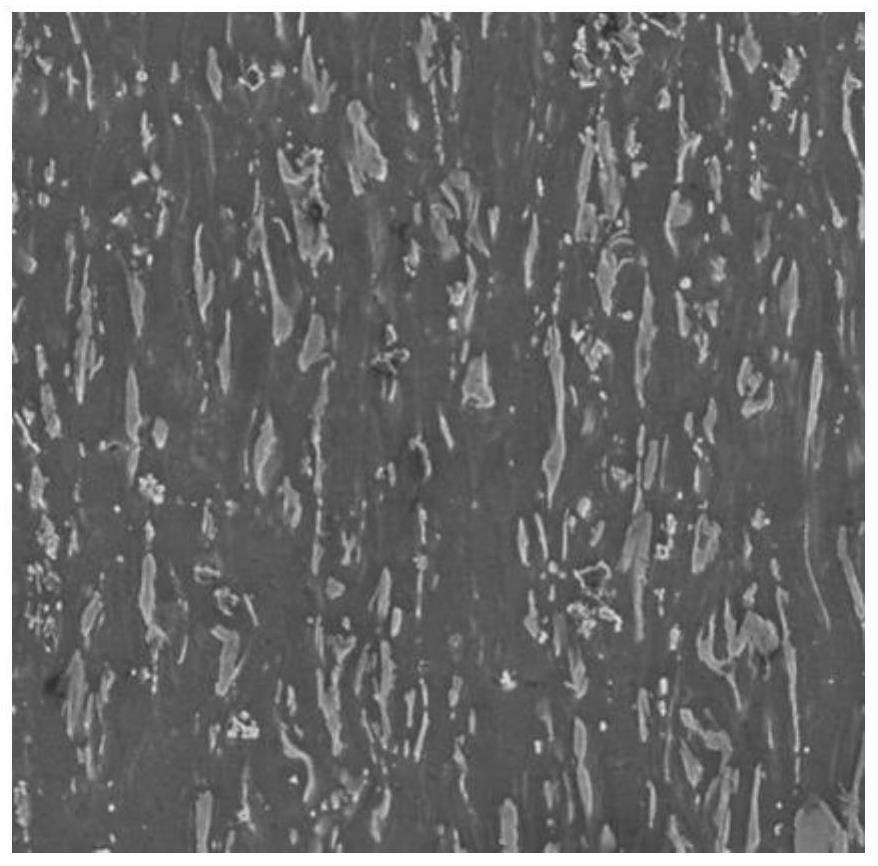

Image

Examples

preparation example Construction

[0045] In the preparation method of the present invention, wherein in step C), the extrusion molding conditions are: the extrusion ratio is (28-50): 1, the extrusion speed is 1-3m / min; the extrusion temperature is 200-300°C , to ensure the complete recrystallization of β-Li; if the extrusion temperature is lower than 200°C, the extrusion ratio is lower than 28, and the extrusion speed is lower than 1m / min, the matrix is not completely recrystallized, and the plasticity is low; if the extrusion If the temperature is higher than 300°C, the extrusion ratio is higher than 50, and the extrusion speed is higher than 3m / min, the surface of the extruded alloy will have burrs, blackening, surface delithiation and other defects.

[0046] The ratios of elements in the alloys in this application and the various process technical parameters in the preparation method are found through experiments and are optimal, because they allow you to obtain the claimed comprehensive technical results....

Embodiment 1

[0048] A kind of high plasticity rapid degradation Mg-Li-Gd-Ni alloy, by mass percentage, its chemical element composition comprises: Gd 6.0%, Ni 0.5%, Li 8%, the rest is Mg and unavoidable impurity, described impurity The total content is less than or equal to 0.3%.

[0049] The present invention also provides a kind of preparation method of high plasticity rapid degradation Mg-Li-Gd-Ni alloy, comprising the following steps:

[0050] 1) Pretreatment: Grinding the surface of industrial pure magnesium ingots, magnesium-lithium master alloys, magnesium-gadolinium master alloys and magnesium-nickel master alloys to remove the oxide layer on the surface, and place them in industrial alcohol in turn, then place them in an ultrasonic cleaner medium cleaning;

[0051] 2) Put the pretreated pure magnesium ingot, magnesium-lithium master alloy, magnesium-gadolinium master alloy and magnesium-nickel master alloy into the crucible according to the ratio of the above-mentioned mass fract...

Embodiment 2

[0056] A kind of high plasticity rapid degradation Mg-Li-Gd-Ni alloy, by mass percentage, its chemical element composition comprises: Gd 6.0%, Ni 1.0%, Li 8%, the rest is Mg and unavoidable impurity, described impurity The total content is less than or equal to 0.3%.

[0057] The present invention also provides a kind of preparation method of high plasticity rapid degradation Mg-Li-Gd-Ni alloy, comprising the following steps:

[0058] 1) Pretreatment: Grinding the surface of industrial pure magnesium ingots, magnesium-lithium master alloys, magnesium-gadolinium master alloys and magnesium-nickel master alloys to remove the oxide layer on the surface, and place them in industrial alcohol in turn, then place them in an ultrasonic cleaner medium cleaning;

[0059] 2) Put the pretreated pure magnesium ingot, magnesium-lithium master alloy, magnesium-gadolinium master alloy and magnesium-nickel master alloy into the crucible according to the ratio of the above-mentioned mass fract...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com