Novel sheet metal modification system and method based on current energy field assistance

A metal sheet and field-assisted technology, applied in the field of new metal sheet modification system, can solve the problems of inability to prepare large-sized, shortened mold life, increased costs, etc., to reduce the anisotropy of mechanical properties, reduce surface oxidation, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

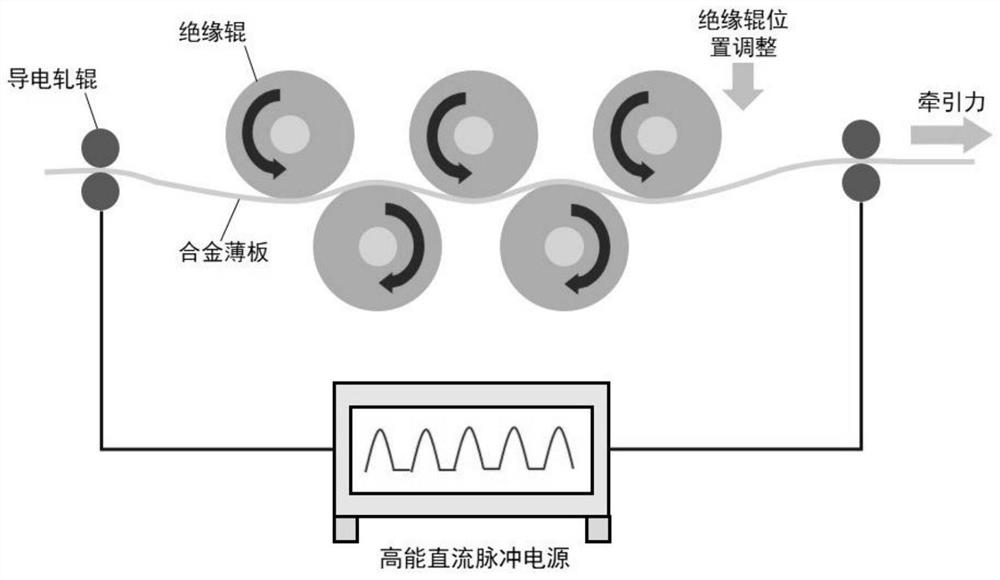

[0032] Such as figure 1 As shown, the present embodiment is a new metal thin plate modification system based on current energy field, including: metal sheet modified load platform, load platform, first conductive roll set, second conductive roll set and 10000A / 24V high Flow low pressure flow pulse power supply; metal thin plate modified load platform is mounted on the load platform; the metal thin plate modified load platform includes an upper insulating roller set and a lower insulating roller set, an upper insulating roller group including a plurality of upper insulating rollers, a lower insulating roller group Including a plurality of lower insulating sticks; a moral arrangement of the upper insulating roller and the lower layer insulating roller, the upper layer insulating roller and the lower layer insulating roller are distributed; the insulating roller is 24mm; between the upper insulating roller set and the lower insulating roller set for curved metal sheets The relative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com