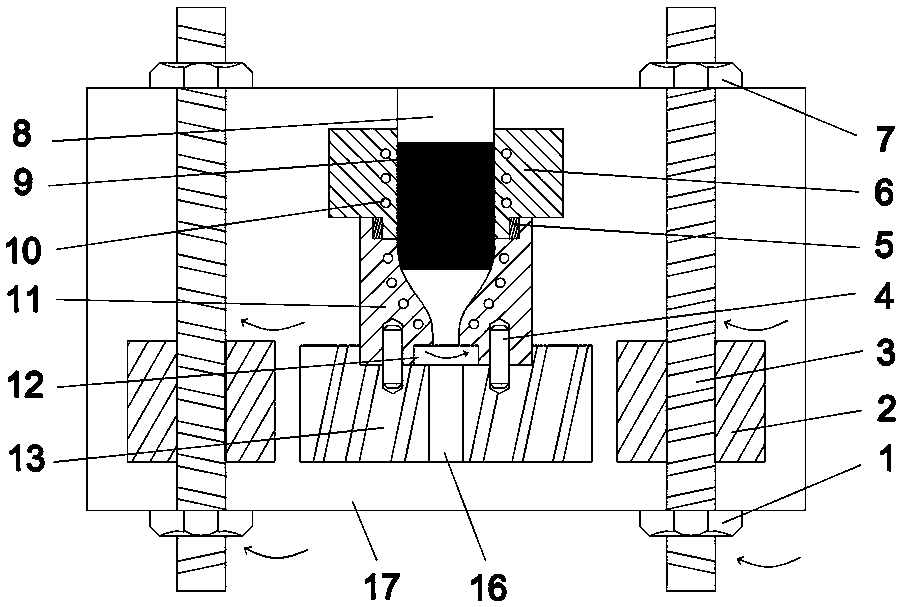

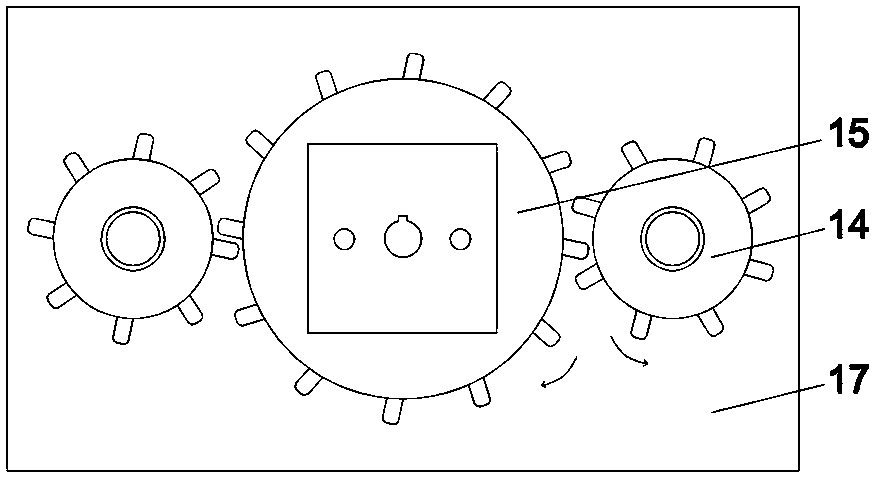

Screw-driven synchronous extruding and twisting composite device for fine-grain magnesium alloy and processing method

A technology of screw transmission and compound device, which is applied in the direction of metal processing equipment, metal extrusion, metal extrusion die, etc., can solve the problems of non-continuous production and low efficiency of processing methods, achieve continuous processing and production, and improve the use of Range, the effect of improving the comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

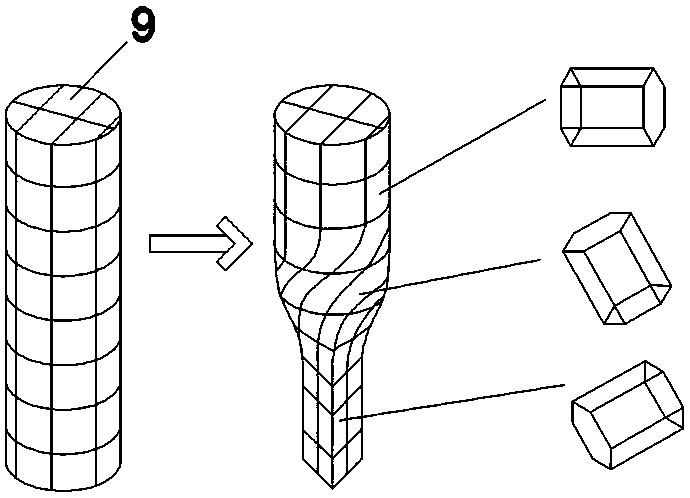

[0036] A processing method of a screw-driven fine-grained magnesium alloy synchronous extrusion and twisting composite device, comprising the following steps:

[0037] S1. Material selection: solid block magnesium alloy billet 9, AZ31 magnesium alloy bar with circular cross section, diameter Φ80mm, length 100mm, magnesium content 95%, aluminum content 3.0%, zinc content 1.0% , the rest are Mn, Fe and other elements, solid sandpaper, made of SiC particles, the order of mesh is 600#, 1000#, 1200#, 2500#, solid powder high temperature graphite, 99.5% of 1200ml liquid liquid Absolute ethanol, 99% acetone of 800ml liquid liquid;

[0038] S2. Pretreatment 1: Grinding the magnesium alloy blank 9 with coarse sandpaper to remove surface impurities and burrs, and then using fine sandpaper of different meshes in order of mesh to remove the surface of the magnesium alloy blank 9 Oxide layer to reduce friction;

[0039] S3, pretreatment 2: preparing blank cleaning solution, the proportio...

Embodiment 2

[0047] A processing method of a screw-driven fine-grained magnesium alloy synchronous extrusion and twisting composite device, comprising the following steps:

[0048] S1. Material selection: solid block magnesium alloy billet 9, AZ61 magnesium alloy bar with square section, cross-sectional area of 60×60mm 2 , the length is 100mm, the magnesium content is 92%, the aluminum content is 6.0%, the zinc content is 1.0%, and the rest are Mn, Fe and other elements, solid sandpaper, the material is SiC particles, and the mesh number is from small to large. It is 600#, 1000#, 1200#, 2500#, high-temperature graphite in solid powder, 99.5% absolute ethanol in 1200ml liquid liquid, and 99% acetone in 800ml liquid state;

[0049] S2. Pretreatment 1: Grinding the magnesium alloy blank 9 with coarse sandpaper to remove surface impurities and burrs, and then using fine sandpaper of different meshes in order of mesh to remove the surface of the magnesium alloy blank 9 Oxide layer to reduce ...

Embodiment 3

[0058] A processing method of a screw-driven fine-grained magnesium alloy synchronous extrusion and twisting composite device, comprising the following steps:

[0059] S1. Material selection: solid block magnesium alloy billet 9, Mg-8Li-1Al-1Zn alloy round ingot, diameter Φ100mm, length 100mm, magnesium content 95%, lithium content 8.0%, aluminum content The content is 1.0%, the zinc content is 1.0%, the rest is Mn, Fe and other elements, solid sandpaper, the material is SiC particles, the mesh number is 600#, 1000#, 1200#, 2500#, solid Powdered high-temperature graphite, 99.5% absolute ethanol in 1200ml liquid, 99% acetone in 800ml liquid;

[0060] S2. Pretreatment 1: Grinding the magnesium alloy blank 9 with coarse sandpaper to remove surface impurities and burrs, and then using fine sandpaper of different meshes in order of mesh to remove the surface of the magnesium alloy blank 9 Oxide layer to reduce friction;

[0061] S3, pretreatment 2: preparing blank cleaning soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com