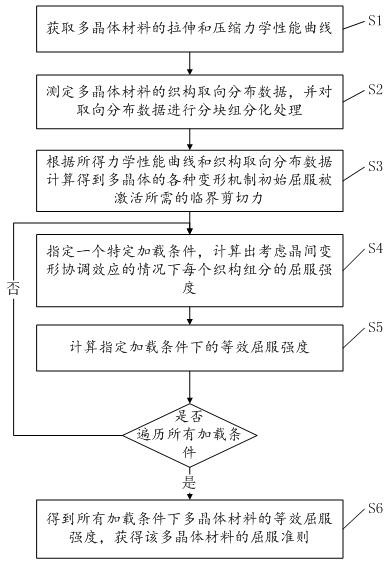

Method for obtaining yield criterion of polycrystalline metal material

A technology of metal materials and acquisition methods, applied in the field of materials, can solve the problems of low calculation efficiency, large calculation amount, difficult to popularize and apply, etc., and achieve the effect of reducing calculation amount and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

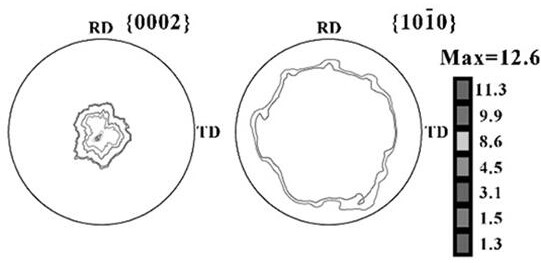

[0072] In this embodiment, a rolled AZ31 magnesium alloy plate is used as the test object.

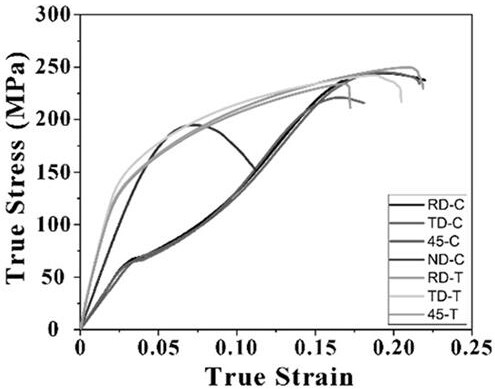

[0073] In step S1, during the mechanical performance test, tension and pressure are applied to the rolling direction (RD direction, equivalent to the length direction), tension and pressure are applied to the width direction (TD direction), and the inner surface of the plate is Tension and pressure are applied in the direction of 45° (that is, the direction that forms an angle of 45° with the length direction in the plate surface), and pressure is applied in the direction of its thickness (ND direction). The true stress-strain curves obtained in each direction are as follows: image 3 shown;

[0074] image 3 Among them, RD-C is the compressive true stress-strain curve in the rolling direction, TD-C is the compressive true stress-strain curve in the width direction, 45-C is the compressive true stress-strain curve in the direction of 45° in the plate surface, and ND-C is The compress...

Embodiment 2

[0079] In this embodiment, the AZ31+0.2Ca magnesium alloy extruded plate is used as the test object. Compared with the plate in Example 1, the texture is weaker, the yield strength is lower, but the plasticity is better. The test flow and data processing flow are the same as those in Embodiment 1.

[0080] The obtained true stress-strain curves in each direction are as follows: Figure 6 As shown in the figure, ED-C is the compressive true stress-strain curve in the extrusion direction (equivalent to the length direction), TD-C is the compressive true stress-strain curve in the width direction, and ED-T is the tensile true stress-strain curve in the extrusion direction. Stress-strain curve, TD-T is the tensile true stress-strain curve in the width direction, VPSC is the VPSC simulation fitting result used to obtain the critical shear force parameters of the deformation mechanism.

[0081] The measured texture orientation was as Figure 5 shown.

[0082] The yield traces of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com