Metal plate texture adjusting and control method

A metal sheet and texture technology, applied in the field of sheet metal processing, to achieve the effect of ensuring the flatness and deformation uniformity of the sheet, improving the stamping performance at room temperature, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The magnesium-aluminum alloy extruded sheet with a thickness of 1.2 mm has a strong base texture and poor stamping performance at room temperature (cupping value is 2.8).

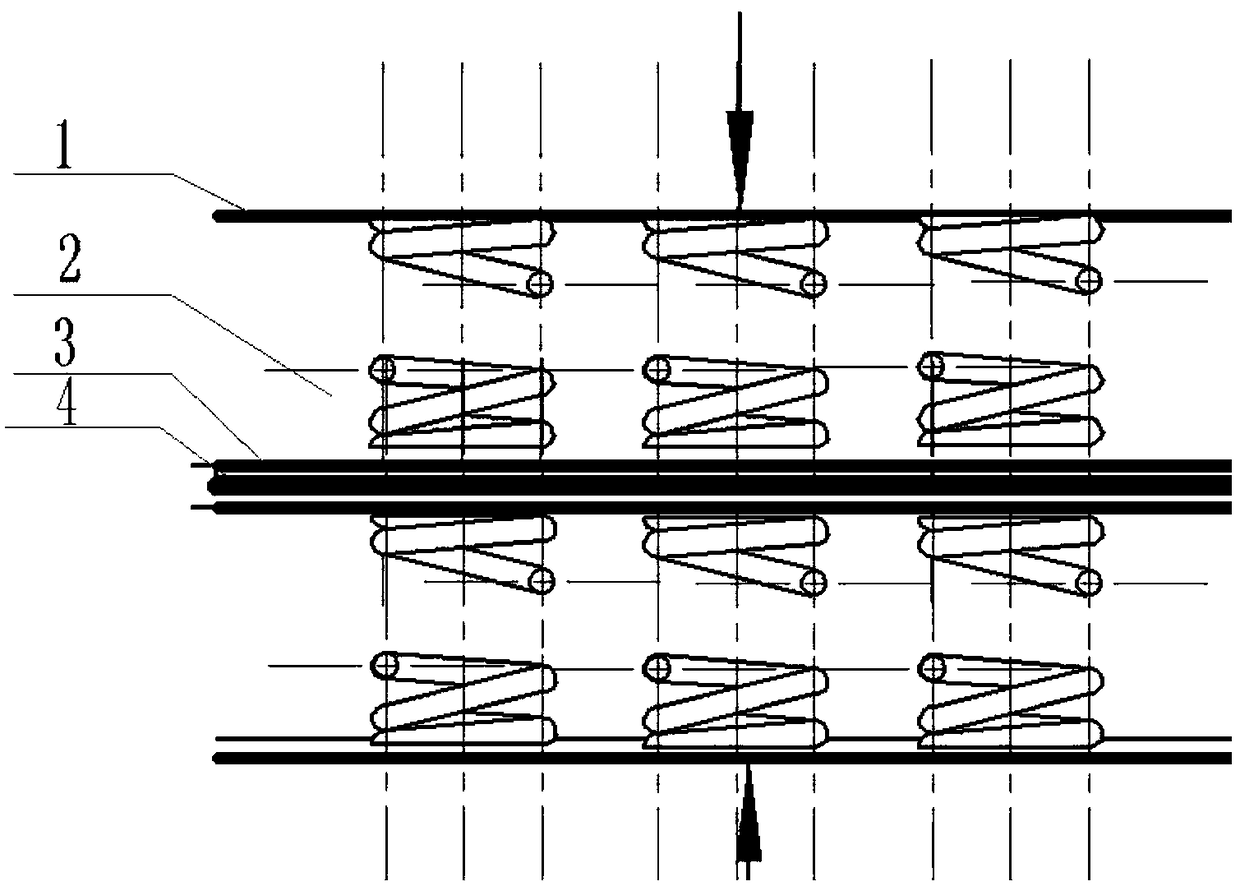

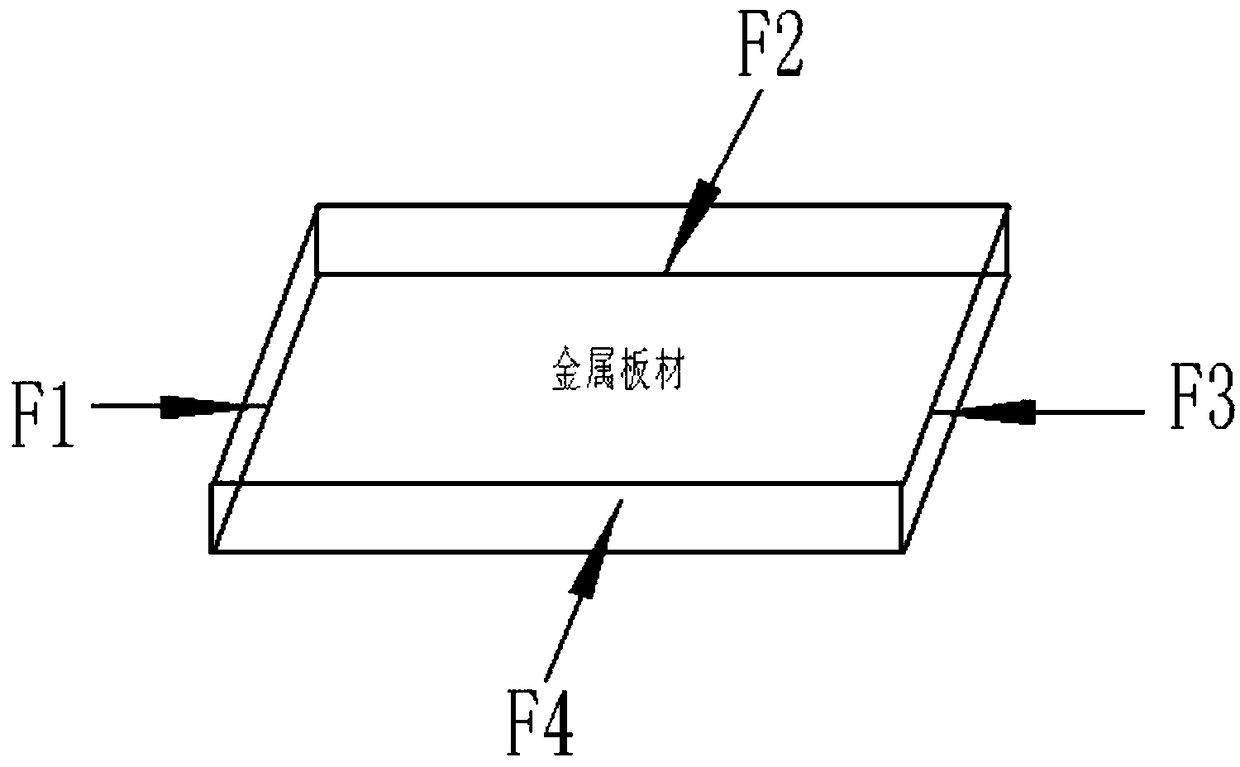

[0020] pass figure 1 Fix the steel plate in the way shown, and the upper and lower loads are 20KN; refer to figure 2 The direction of force shown is marked, F2 and F4 are fixed, F1 and F3 are activated, the deformation rate is 2mm / min, the deformation displacement is 7mm, and the thickness of the plate after deformation is 1.31mm. After annealing at 320°C for 90 minutes, the texture deflects to F1 and F3 directions, forming a bimodal texture, which significantly weakens the basal texture, and the stamping performance (cup value) at room temperature is 7.2.

Embodiment 2

[0022] A 1.1 mm thick AZ31 magnesium alloy rolled plate is used, and its texture is a strong basal texture, and its stamping performance at room temperature is poor (cupping value is 3.1).

[0023] pass figure 1 Fix the steel plate in the way shown, and the upper and lower loads are 15KN; refer to figure 2 The direction of the force shown is fixed, F1 and F3 are fixed, and F2 and F4 are activated. The deformation rate is 1.5mm / min, the deformation displacement is 5mm, and the thickness of the plate after deformation is 1.18mm. After annealing at 320°C for 60 minutes, the texture deflects to the F2 and F4 directions, forming a bimodal texture, which obviously weakens the basal texture, and the stamping performance (cupping value) at room temperature is 7.6.

Embodiment 3

[0025] The extruded sheet of magnesium-aluminum-tin alloy with a thickness of 1 mm has a strong base surface texture and poor stamping performance at room temperature (cupping value is 2.7).

[0026] pass figure 1 Fix the steel plate in the way shown, and the upper and lower loads are 10KN; refer to figure 2 As shown in the direction of the force, fix F1 and F2, start F3 and F4, the deformation rate of F3 is 1mm / min, the deformation rate of F3 is 0.5mm / min, and the deformation displacement is 5 and 3mm respectively. After deformation, the plate becomes thicker to 1.06mm. After annealing at 300°C for 60 minutes, the texture deflects to the F3 and F4 directions, forming an asymmetric bimodal texture, which significantly weakens the basal texture, and the room temperature stamping performance (cupping value) is 8.1.

[0027] From the above examples, it can be explained that the present invention fixes the metal plate through the upper and lower loading forces, and at the same ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com