Processing method of long-service-life copper manganese alloy target material

A copper-manganese alloy and processing method technology, which is applied in the field of target manufacturing, can solve problems such as not involving Cu-Mn alloy targets, and achieve the effects of improving the life of the target and improving the utilization rate of the target.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

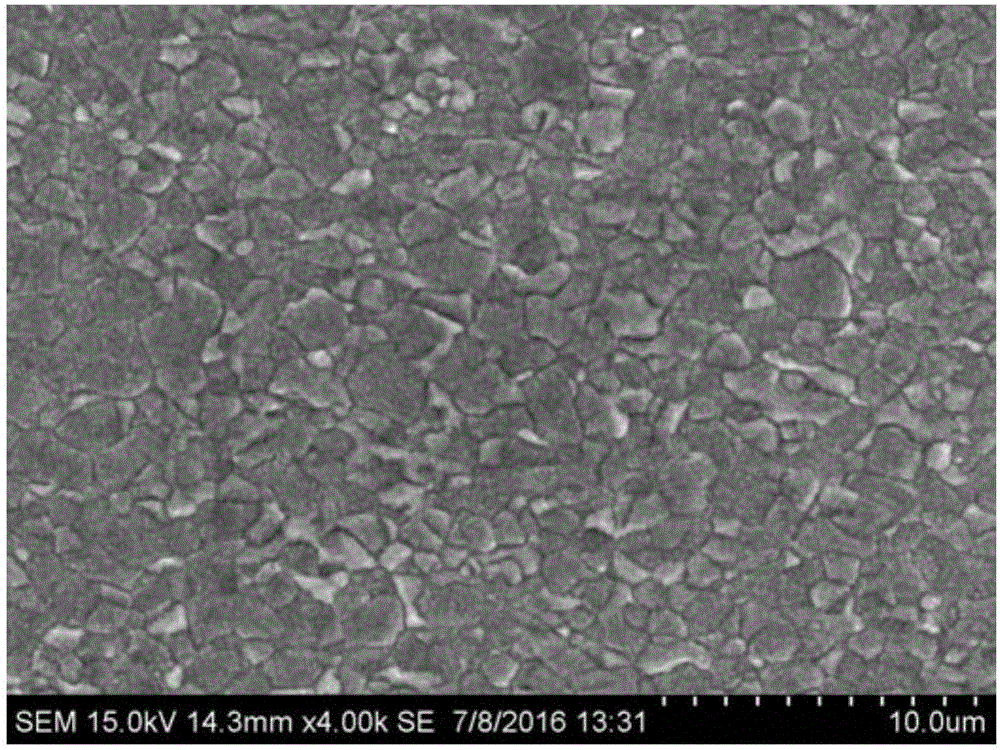

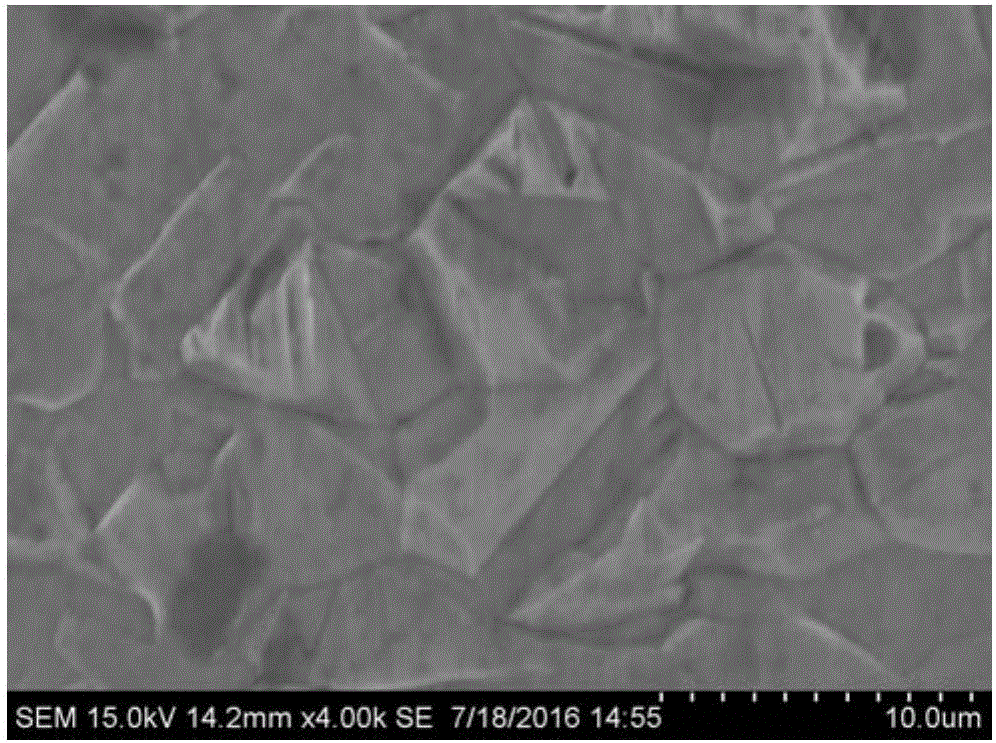

[0031] Embodiment 1-5: the results are shown in Table 1 and Figure 1-Figure 3 shown;

[0032] The specification of the copper-manganese alloy ingot is φ200×260t, and it is hot forged at 500-800°C. The forging method is X / Y / Z three-way upsetting and drawing, and the upsetting and drawing ratio is 2:1. System φ580×30t; then recrystallization heat treatment to obtain the original billet.

[0033] Use friction stir processing for grain refinement at a rotational speed of 400-600r / min to obtain a long-life copper-manganese alloy sputtering target. Water cooling is carried out during the grain refinement process, and then the blank is subjected to 300°C stress relief annealing.

[0034] The results obtained are shown in Table 1. It can be seen that under the condition of the rotational speed of 400-600r / min, friction stir processing is used for grain refinement, and the average grain size of the obtained long-life copper-manganese alloy sputtering target is below 5 μm. With the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com