Rolling method of sheet metal

A technology for metal sheets and plates, applied in metal rolling and other directions, can solve the problems of many processes and low production efficiency, and achieve the effects of reducing production costs, improving rolling efficiency, and reducing edge cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

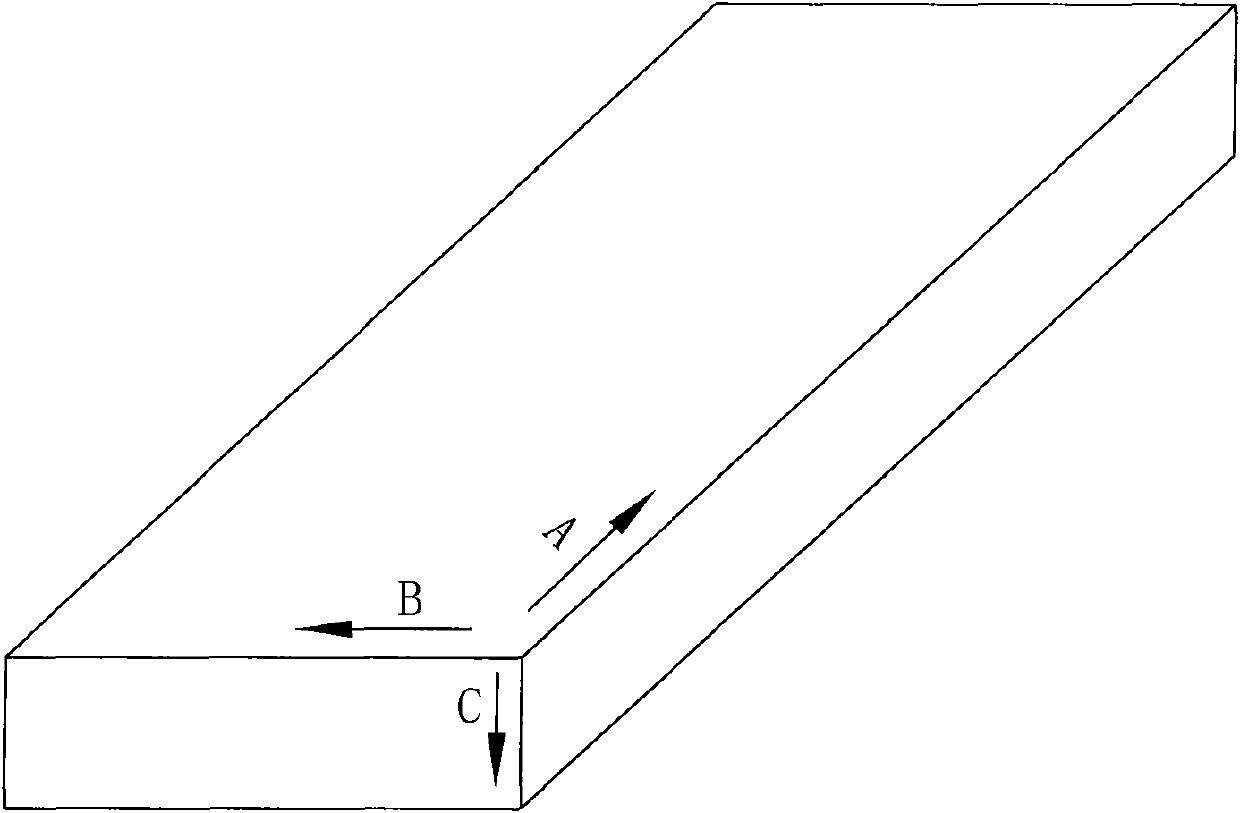

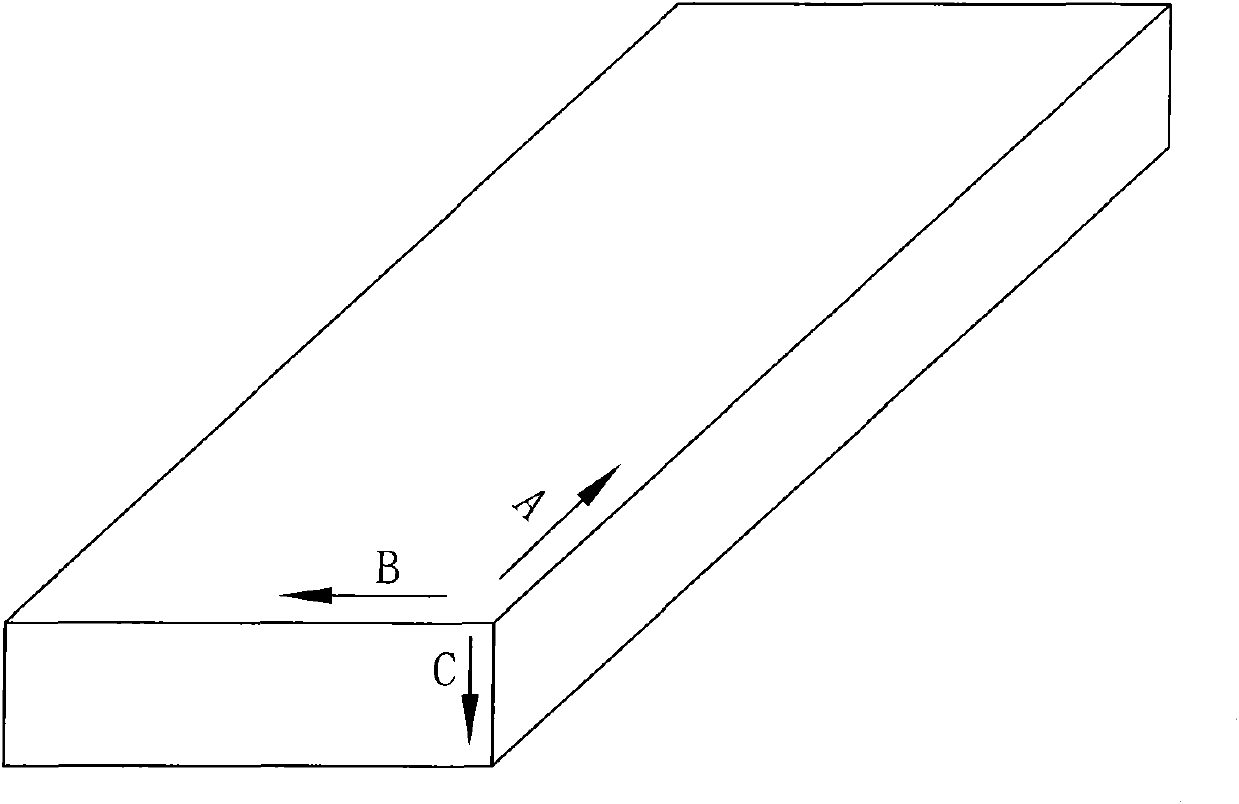

[0017] First, a magnesium alloy plate is pretreated, that is, at 400°C along the transverse direction of the plate ( figure 1 A direction is the rolling direction, B direction is the transverse direction, and C direction is the normal direction) to apply compressive stress, the compressive stress is greater than the yield stress of the plate in the transverse direction, so the plate will produce plastic strain, when the strain reaches 20% , stop the pretreatment, and then send the plate into the roll rolling, the temperature of the roll is normal temperature, the reduction is 63%, and the obtained magnesium alloy plate does not have defects such as edge cracks.

[0018] In Example 1, the (0002) base plane is perpendicular to the transverse direction and parallel to the normal direction by applying compressive stress along the transverse direction of the plate, effectively reducing the texture of the base plane (that is, the plane perpendicular to the normal direction) Therefor...

Embodiment 1

[0023] Apply a compressive stress to the same magnesium alloy plate as in Example 1 at 400°C along the normal direction of the plate, the compressive stress is greater than the yield stress of the plate in the normal direction, so the plate will produce plastic strain, when the strain reaches 20% , stop applying the compressive stress, then the plate is sent into the rolls for rolling, the roll temperature is normal temperature, the reduction is 63%, and the obtained magnesium alloy plate has a small amount of edge cracking.

Embodiment 2

[0025] A magnesium alloy plate identical to that of Example 1 was directly sent into rolls for rolling, and the roll temperature was normal temperature and the reduction was 63%, and the obtained magnesium alloy plate was severely cracked.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com