A kind of corrosion-resistant biomedical magnesium alloy and its preparation method and application

A biomedical and magnesium alloy technology, applied in the field of biomedical metal materials, can solve problems such as unsatisfactory, mechanical performance degradation, and inflammation, and achieve the effects of reducing potential difference, improving rolling formability, and improving corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

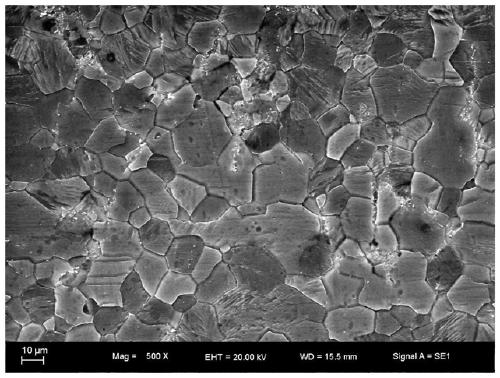

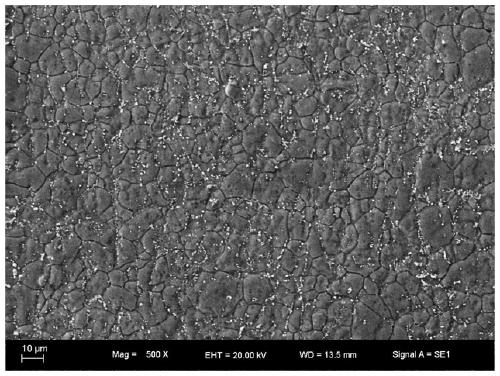

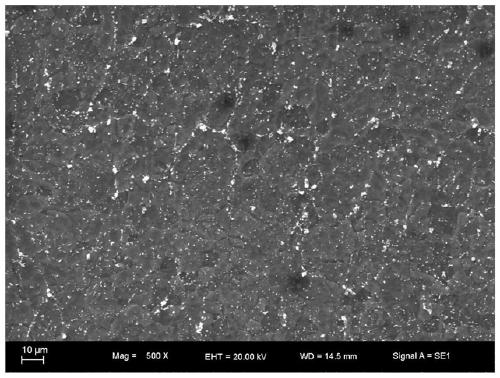

Image

Examples

preparation example Construction

[0048] The invention provides a method for preparing a corrosion-resistant biomedical magnesium alloy, comprising the following steps:

[0049] Step 1, cleaning the surfaces of the raw material high-purity magnesium, pure zinc, pure tin and magnesium-calcium master alloy;

[0050] Step 2. Put the crucible into the resistance furnace for preheating, and then pass the first protective gas into the furnace, put the high-purity magnesium into the crucible, raise the furnace temperature until the high-purity magnesium ingot is completely melted, and perform slag removal; then lower the furnace temperature, Then add pure tin, pure zinc, and magnesium-calcium intermediate alloy into the crucible; after the alloy material is melted and stirred at a constant speed, let it stand still;

[0051] Step 3: pour the melt into the preheated copper mold at a constant speed after slag removal, and demould after solidification to obtain the magnesium alloy ingot;

[0052] Step 4, cutting the ingo...

Embodiment 1

[0067] (1) by the mass percent of element in the alloy: tin 0.8%, zinc 1%, calcium 0.25%, all the other are magnesium, take required high-purity magnesium, pure tin, pure zinc, magnesium-30% calcium intermediate alloy, and The raw materials are polished with grinding wheels to remove surface oxides;

[0068] (2) Melting: Put the crucible in a resistance furnace to preheat, and after the temperature of the furnace rises to 500°C, put CO into the furnace 2 and SF 6 Mixed gas; among them, CO 2 and SF 6 The volume ratio of the flow rate is 100:1; put the high-purity magnesium ingot into the crucible after passing the protective gas for 5-10 minutes, raise the furnace temperature to 700°C, and perform slag breaking after the high-purity magnesium ingot is completely melted. Then the furnace temperature is lowered to 680°C, and then pure tin, pure zinc, and Mg-30Ca intermediate alloy are added to the crucible; after the alloy material is melted, stir at a constant speed and count...

Embodiment 2

[0074] (1) by the mass percent of element in the alloy: tin 3%, zinc 1.25%, calcium 0.05%, all the other are magnesium, take required high-purity magnesium, pure tin, pure zinc, magnesium-30% calcium intermediate alloy, and The raw materials are polished with grinding wheels to remove surface oxides;

[0075] (2) Melting: Put the crucible in a resistance furnace to preheat, and after the temperature of the furnace rises to 500°C, put CO into the furnace 2 and SF 6 Mixed gas; among them, CO 2 and SF 6 The volume ratio of the flow rate is 100:1; put the high-purity magnesium ingot into the crucible after passing the protective gas for 5-10 minutes, raise the furnace temperature to 700°C, and perform slag breaking after the high-purity magnesium ingot is completely melted. Then the furnace temperature is lowered to 680°C, and then pure tin, pure zinc, and Mg-30Ca intermediate alloy are added to the crucible; after the alloy material is melted, stir at a constant speed and coun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com