Method for directly preparing thin strip from ferric oxide

A technology for thin strip steel and iron oxide, applied in metal rolling and other directions, can solve the problems of complex preparation process, harsh operating environment and high cost, and achieve the effect of less equipment maintenance, improved strip density and short process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

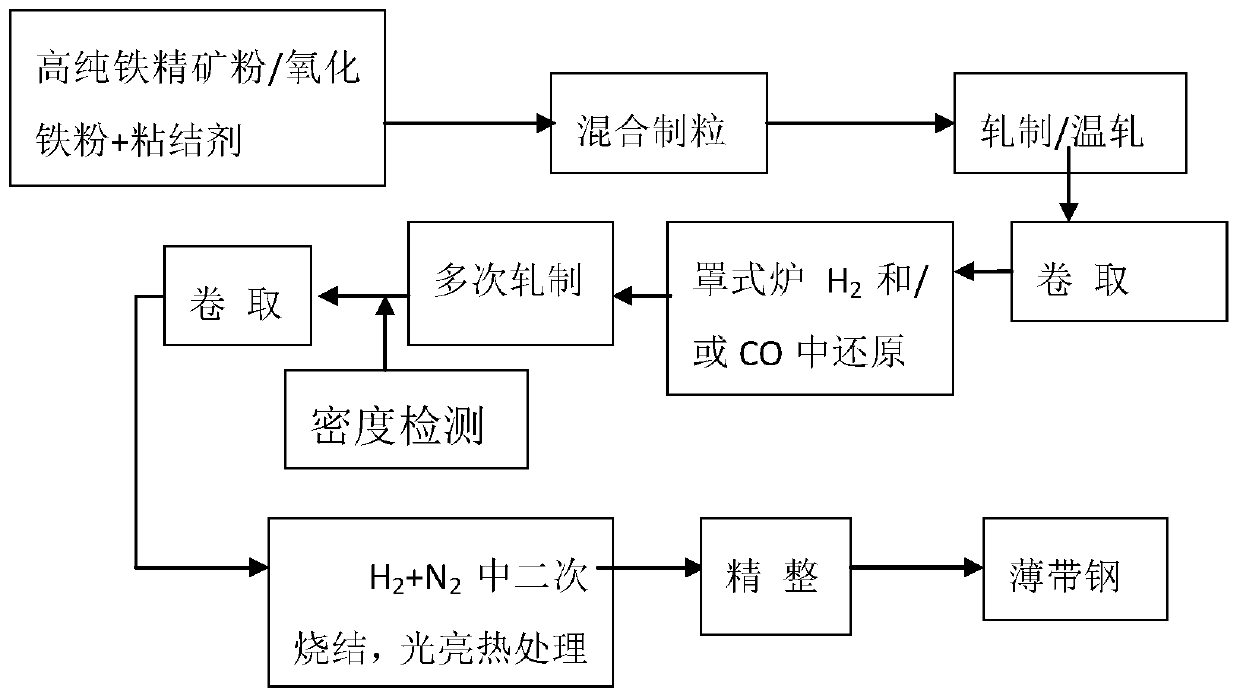

[0042] Example one: the preparation of ultra-low C thin strip steel, such as figure 1 Shown:

[0043] Step 1, raw material preparation: content 99.8% high-purity Fe 2 o 3 The amount of powder added is 100g, organic binder cellulose is 1.0g, the raw materials are weighed according to the proportion, mixed in the mixer for 60min and granulated, and the particle size is 1.5mm to increase the fluidity;

[0044] Step 2, initial rolling and coiling: the raw material of 1.5mm particles is rolled in a powder vertical rolling mill according to a conventional method, and the strip thickness is controlled at 4.6-5.0mm, and coiled; the initial rolling thin strip The density is 5.3g / cm 3 ;

[0045]Step 3, place the billet in a bell furnace for initial reduction, the medium in the bell furnace is H 2 gas, the initial reduction temperature is 950°C, and the reduction time is 3 hours;

[0046] Step 4, the strip after reduction is rolled four times in the horizontal rolling mill, the thi...

example 2

[0051] Example two. Containing C thin steel strip preparation, such as figure 1 Shown:

[0052] Step 1, raw material preparation: add 100g of 200 mesh super iron ore concentrate powder with 72.1% Fe content, 0.8g of organic binder cellulose, weigh the raw materials according to the proportion, mix them in a mixer for 40min and granulate, Particles with a particle size of 1.5mm increase fluidity;

[0053] Step 2, initial rolling and coiling: the raw material of 1.5mm particles is warm-rolled at a temperature of 110°C in a powder vertical rolling mill, and the thickness of the strip is controlled at 3.2-3.5mm, and coiled; the initial rolling is thin Strip density is 5.9g / cm 3 ;

[0054] Step 3, place the billet in a bell furnace for initial reduction, the medium in the bell furnace is 40% H 2 +35%CO+25%N 2 , the initial reduction temperature is 1100°C, and the reduction time is 2.0 hours;

[0055] Step 4. The strip after reduction is rolled four times in a horizontal rolli...

example 3

[0059] Example three. Containing C thin steel strip preparation, such as figure 1 Shown:

[0060] Step 1, raw material preparation: add 100g of 150 mesh super iron ore concentrate powder with 71.5% Fe content, 0.5g of organic binder cellulose, weigh the raw materials according to the proportion, mix them in a mixer for 30min and granulate, Particles with a particle size of 1.5mm increase fluidity;

[0061] Step 2, initial rolling and coiling: the raw material of 1.5mm particles is carried out warm rolling at a temperature of 150°C in a powder vertical rolling mill, and the strip thickness is controlled at 2.0-2.3mm and coiled; the initial rolling is thin Strip density is 6.3g / cm 3 ;

[0062] Step 3, place the billet in a bell furnace for initial reduction, the medium in the bell furnace is 40% H 2 +35%CO+25%N 2 , the initial reduction temperature is 1200°C, and the reduction time is 1 hour;

[0063] Step 4. The strip after reduction is rolled three times in a horizontal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com