Surface modified coating cutting blade and preparation method thereof

A cutting blade and surface modification technology, applied in the field of metal cutting, can solve the problems of insufficient chipping resistance and high deposition temperature, so as to improve the chipping resistance and anti-adhesion performance, improve oxidation resistance, coating Effect of Residual Stress Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

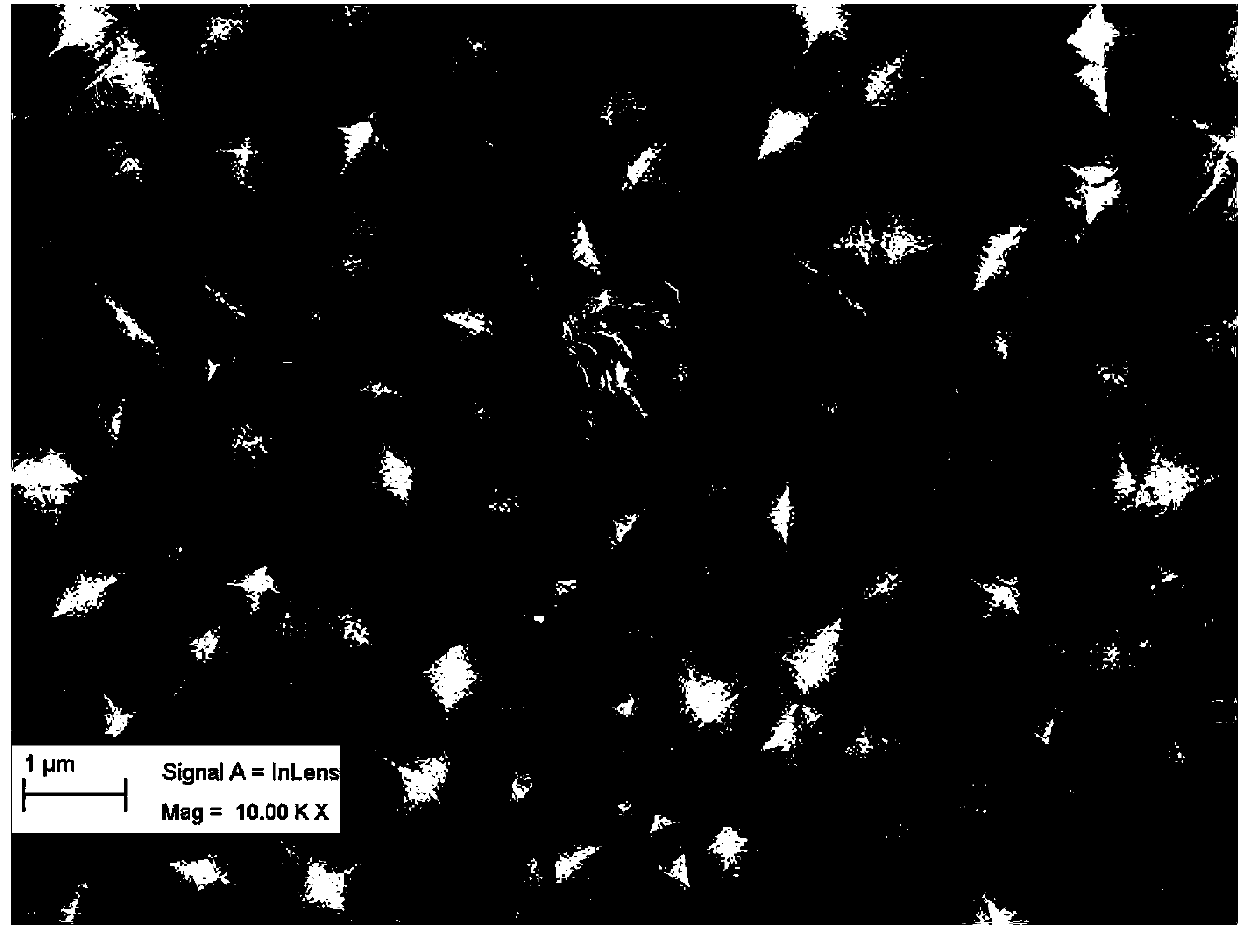

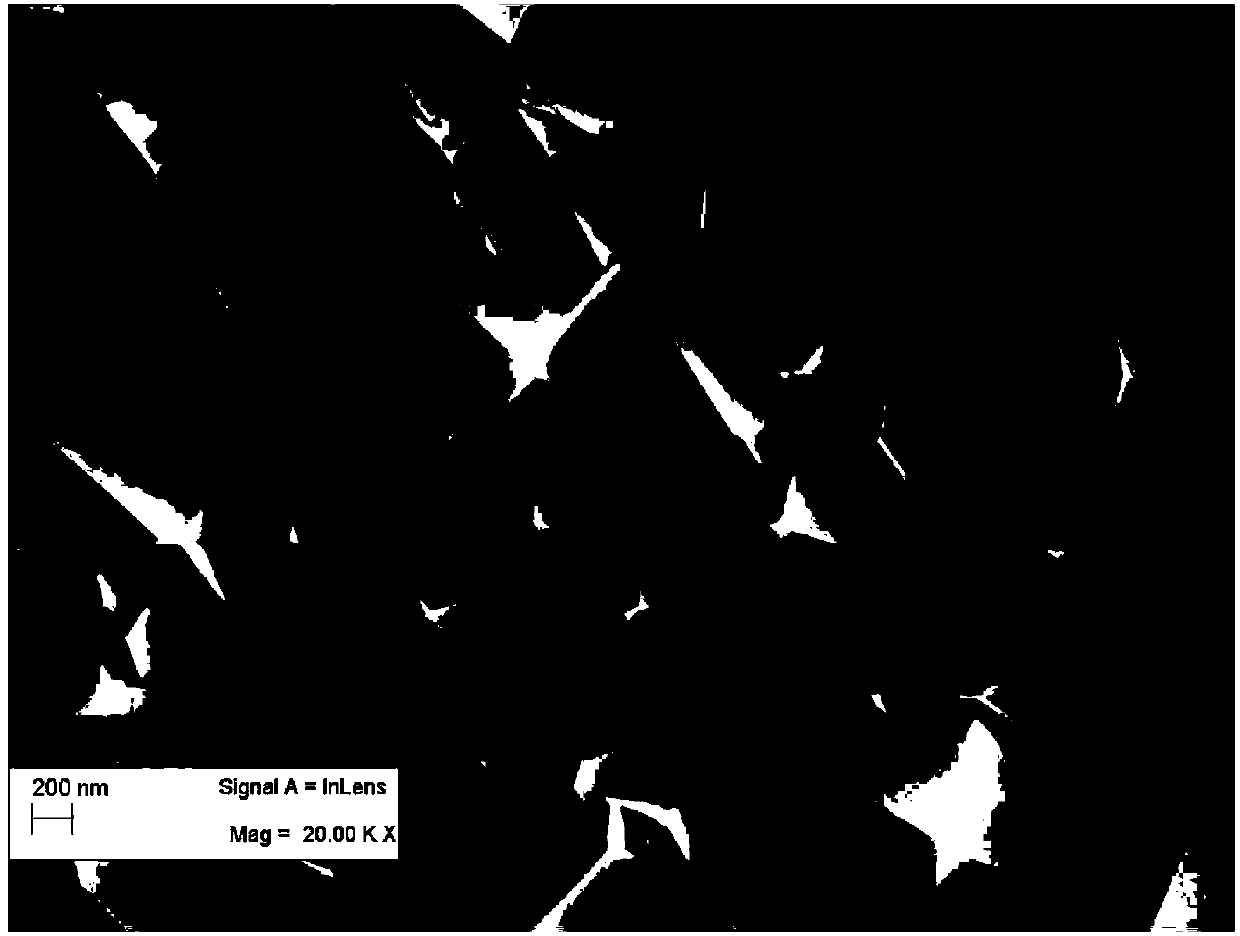

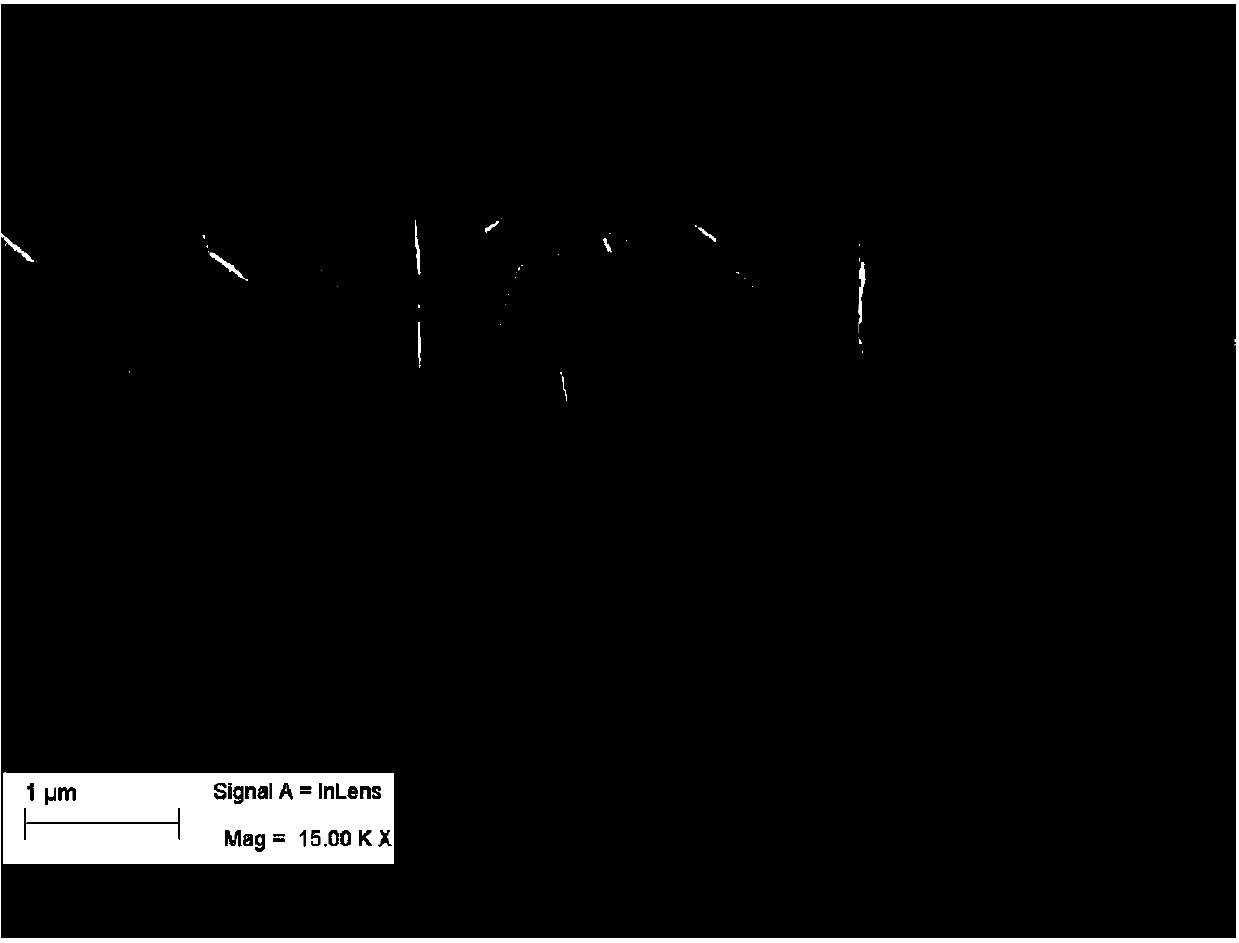

[0046] A surface-modified coating cutting insert of the present invention comprises a cemented carbide insert substrate and a coating deposited on the insert substrate, the coating sequentially includes a TiN layer, an MT-TiZrCN coating, a TiC 0.5 N 0.3 o 0.2 layer, α-Al 2 o 3 layer and Al(Zr) with corundum structure 2 o 3 Modified coating, and Al(Zr) 2 o 3 The modified coating has a strong texture orientation of the (300) crystal plane, and the intensity ratio I(300) / I(110)=2.0 of the orientation crystal plane (that is, the XRD diffraction peaks of the (300) crystal plane and the (110) crystal plane intensity ratio, the same below). The thickness of the TiN layer in the coating is 0.2 μm; the MT-TiZrCN coating is in TiCl 4 -CH 3 CN-HCl-N 2 -H 2 Add ZrCl to the deposition atmosphere system 4 The atmosphere is prepared, the Zr content (atomic percentage, the same below) in the MT-TiZrCN coating is 0.2 at%, the longitudinal surface of the MT-TiZrCN coating is a colum...

Embodiment 2

[0109] A surface-modified coating cutting insert of the present invention comprises a cemented carbide insert substrate and a coating deposited on the insert substrate, the coating sequentially includes a TiN layer, an MT-TiZrCN coating, a TiC 0.6 N 0.3 o 0.1 layer, α-Al 2 o 3 layer and Al(Zr) with corundum structure 2 o 3 Modified coating, and Al(Zr) 2 o 3 The modified coating has a strong texture orientation of (300) crystal plane, and the intensity ratio of the oriented crystal plane is I(300) / I(110)=2.4. The thickness of the TiN layer in the coating is 0.2 μm; MT-TiZrCN coating is in TiCl 4 -CH 3 CN-HCl-N 2 -H 2 Add ZrCl to the deposition atmosphere system 4 Prepared in an atmosphere, the Zr content in the MT-TiZrCN coating is 0.17at%, the longitudinal surface of the MT-TiZrCN coating is a columnar crystal structure, the aspect ratio is ≥ 3, and the thickness of the MT-TiZrCN coating is 5.5 μm; TiC 0 . 6 N 0 . 3 o 0 . 1 The thickness of the layer is 0.5 μm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com