Surface-modified coated cutting tool and preparation method thereof

A cutting tool and surface modification technology, applied in the direction of tools, coatings, turning equipment for lathes, etc., can solve the problems of increasing the preparation process of coating cutting tools, increasing the production cost of tools, etc., to achieve processing performance and processing stability. Good performance, reduce processing cost, reduce the effect of friction and cutting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

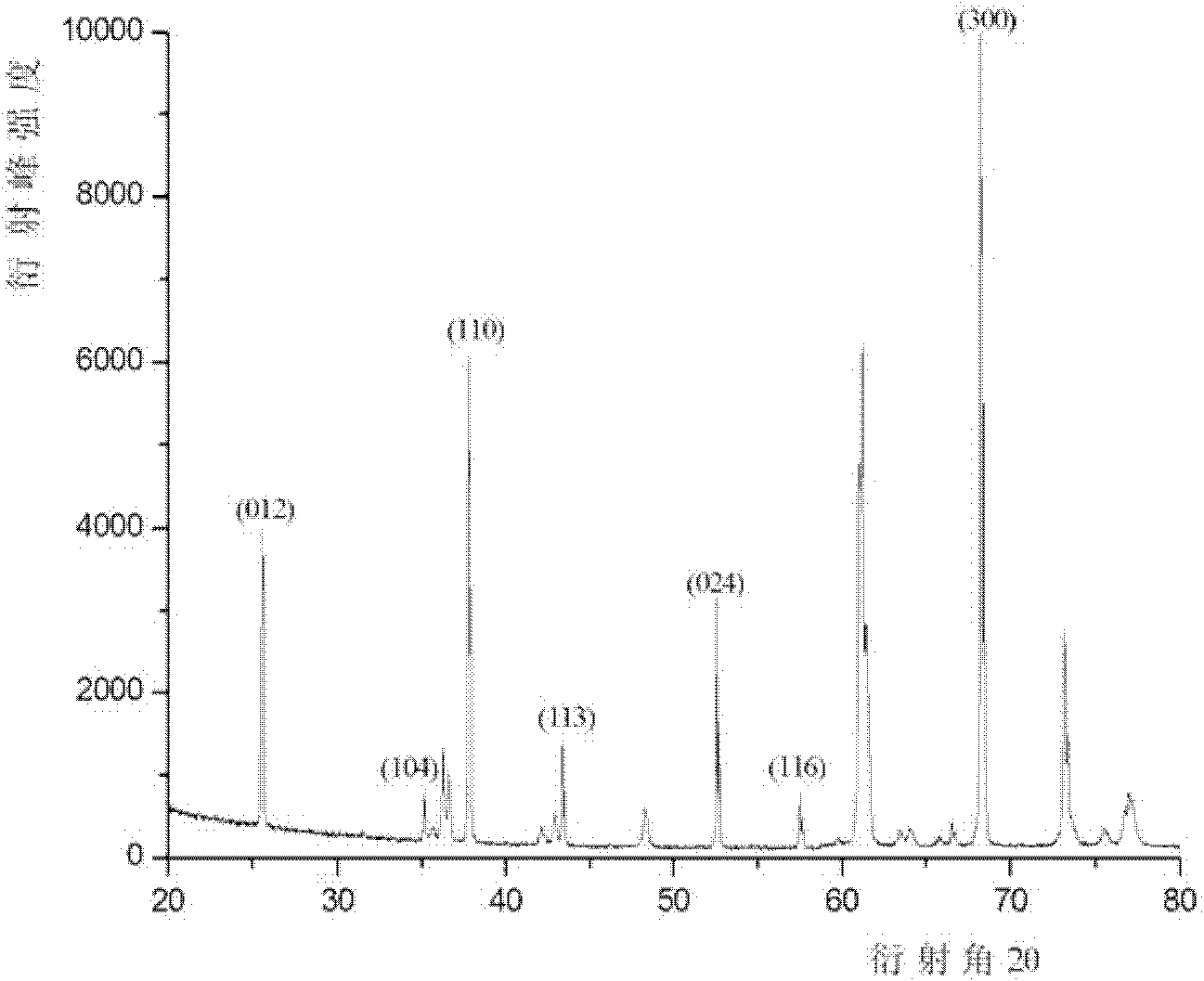

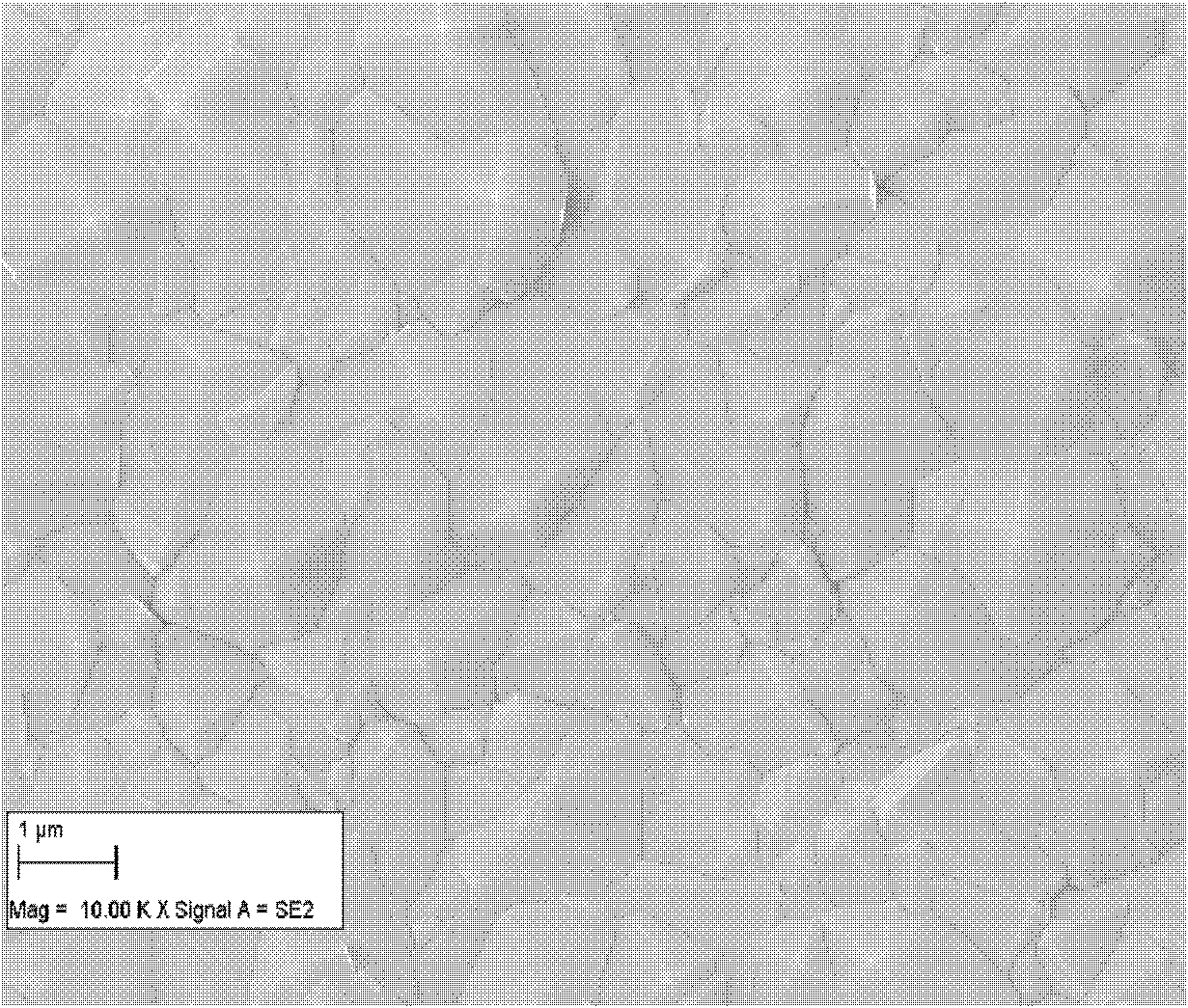

Embodiment 1

[0038] A cutting tool with a surface-modified coating of the present invention comprises a cemented carbide tool substrate and a coating, the tool substrate is coated with a coating, and the coating sequentially includes a TiN layer, a TiCN layer, a TiCO layer, α-Al 2 o 3 layer and Al(Zr) 2 o 3 Modified coating, Al(Zr) in coating 2 o 3 The modified coating has a corundum structure, Al(Zr) 2 o 3 The modified coating has obvious orientations in (110) and (300) crystal planes, and has a columnar structure with extremely smooth surface; Al(Zr) 2 o 3 The texture coefficients of the modified coatings in different orientations are shown in Table 1 below, where TC(110) is 1.92, TC(300) is 3.13, and (012), (104), (113), (024) , (116) crystal plane texture coefficients are ≤1. Al(Zr) 2 o 3 The surface roughness Ra of the modified coating was 0.21 μm. Al(Zr) on the upper and lower surfaces of the cutting tool in this embodiment 2 o 3 The thickness difference of the modified...

Embodiment 2

[0060] A cutting tool with a surface-modified coating of the present invention comprises a cemented carbide tool substrate and a coating, the tool substrate is coated with a coating, and the coating sequentially includes a TiN layer, a TiCN layer, a TiCO layer, α-Al 2 o 3 layer and Al(Zr) 2 o 3 Modified coating, Al(Zr) in coating 2 o 3 The modified coating has a corundum structure, Al(Zr) 2 o 3 The modified coating has obvious orientations in (110) and (300) crystal planes, and has a columnar structure with extremely smooth surface; Al(Zr) 2 o 3 The texture coefficients of the modified coatings in different orientations are shown in Table 4 below, where TC(110) is 3.04, TC(300) is 1.81, and in (012), (104), (113), (024) , (116) crystal plane texture coefficients are ≤1. Al(Zr) 2 o 3 The surface roughness Ra of the modified coating is 0.20 μm. Al(Zr) on the upper and lower surfaces of the cutting tool in this embodiment 2 o 3 The thickness difference of the modifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com