Method for preparing spherical amorphous boron powder by spray drying method

An amorphous boron powder, spray drying technology, applied in chemical instruments and methods, inorganic chemistry, boron compounds, etc., can solve the problem of no spherical amorphous boron powder patents and reports, etc., to achieve a short preparation period, the method is simple and easy Excellent effect of line and sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

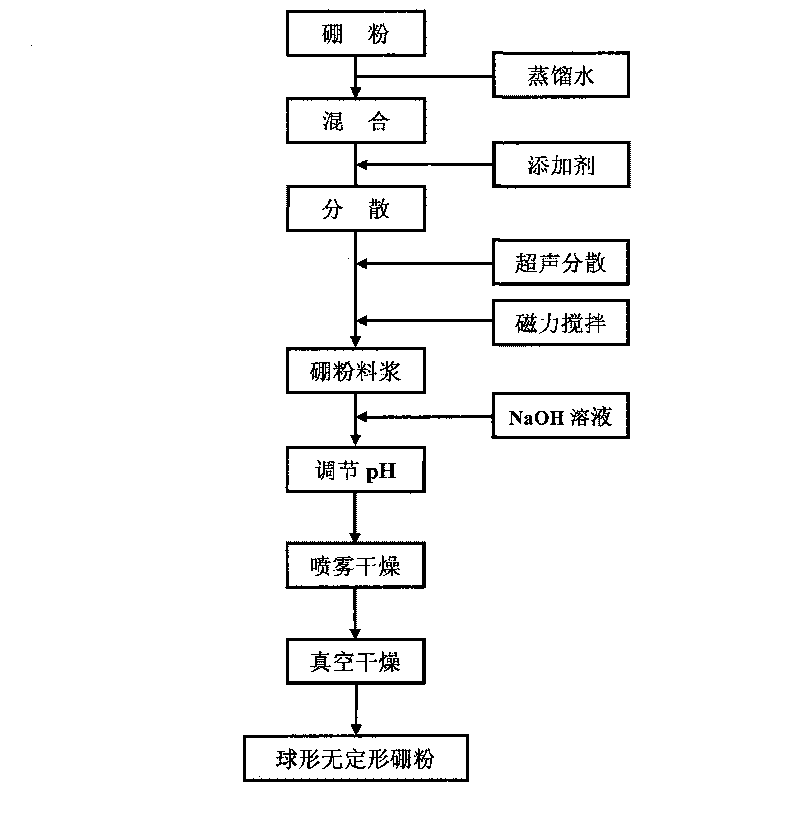

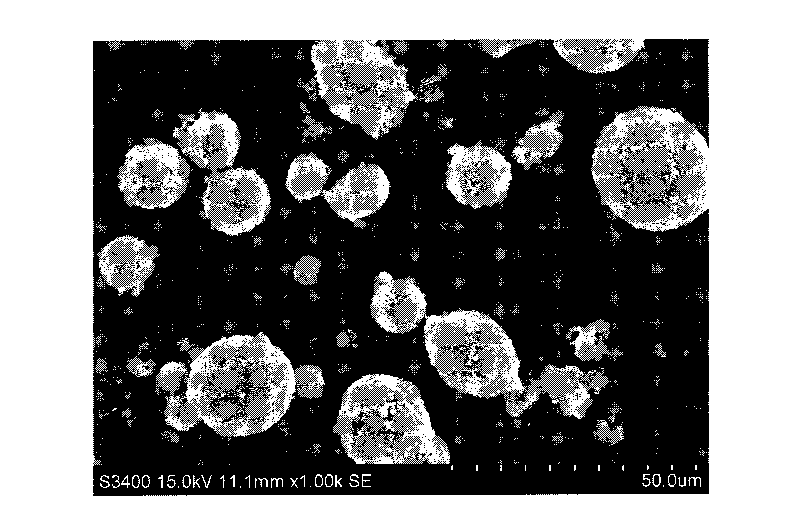

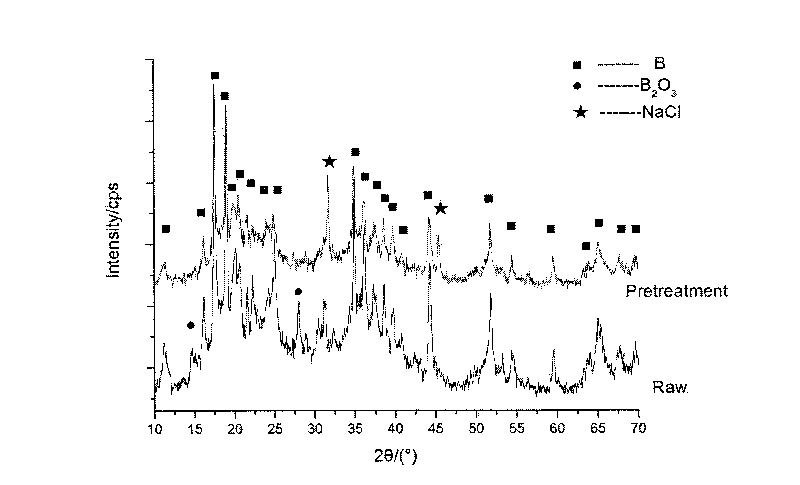

[0028] Such as figure 1 As shown, 40 grams of boron powder and 60 grams of distilled water are evenly mixed. The boron powder is an amorphous boron powder with a particle size of 0.2 to 1 μm and a mass purity of 90%. Add 1.000 grams of polyethylene glycol (molecular weight is 2000), first Ultrasonic dispersion for 30 minutes (ultrasonic frequency is 20KHz-30KHz, power is 140W-160W, the same below), and then magnetically stirred for 30 minutes to obtain a boron powder slurry; use a sodium hydroxide solution with a molar concentration of 2.0mol / L to mix boron The pH value of the powder slurry is adjusted to 10 to obtain the boron powder slurry after adjusting the pH value; then utilize a spray dryer to spray dry the boron powder slurry after adjusting the pH value, first adjust the inlet air temperature of the spray dryer to 140°C, pre-spray with distilled water for 15 minutes, and then spray dry the boron powder slurry. Control the air flow rate of the spray dryer to 40mL / s, an...

Embodiment 2

[0032] Evenly mix 40 grams of boron powder with 60 grams of distilled water. The boron powder is an amorphous boron powder with a particle size of 0.2-1 μm and a mass purity of 95%. Add 0.800 grams of polyethylene glycol (molecular weight: 2000), and first ultrasonically disperse it Minutes, then magnetically stirred for 20 minutes to obtain the boron powder slurry; the pH value of the boron powder slurry was adjusted to 9 by using a sodium hydroxide solution with a molar concentration of 2.0mol / L to obtain the boron powder slurry after adjusting the pH value; Then utilize the spray dryer to spray dry the boron powder slurry after adjusting the pH value, adjust the inlet air temperature of the spray dryer to 130°C, pre-spray with distilled water for 15 minutes, and then spray dry the boron powder slurry to control The air flow rate of the spray dryer is 30mL / s, and the flow rate of the peristaltic pump is 300mL / h. During the whole process, the boron powder slurry is continuousl...

Embodiment 3

[0035] Evenly mix 40 grams of boron powder with 60 grams of distilled water. The boron powder is an amorphous boron powder with a particle size of 0.2-1.2 μm and a mass purity of 85%. Add 2.400 grams of polyethylene glycol (molecular weight: 20,000) and ultrasonically disperse 15 minutes, then magnetically stirred for 15 minutes to obtain a boron powder slurry; using a sodium hydroxide solution with a molar concentration of 2.0mol / L to adjust the pH value of the boron powder slurry to 11, to obtain a boron powder slurry after adjusting the pH value Then utilize the spray dryer to spray dry the boron powder slurry after adjusting the pH value, adjust the inlet air temperature of the spray dryer to 150°C, pre-spray with distilled water for 15 minutes, and then spray dry the boron powder slurry, Control the air flow rate of the spray dryer to 50mL / s, and the flow rate of the peristaltic pump to 500mL / h. During the whole process, the boron powder slurry is continuously magnetically...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com