Boron carbide-titanium boride lightweight high-strength composite ceramic material and preparation method thereof

A technology of composite ceramics and titanium boride, applied in the field of ceramic materials, can solve the problems of high theoretical bulk density and the inability to adjust the composition of ceramic composite materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

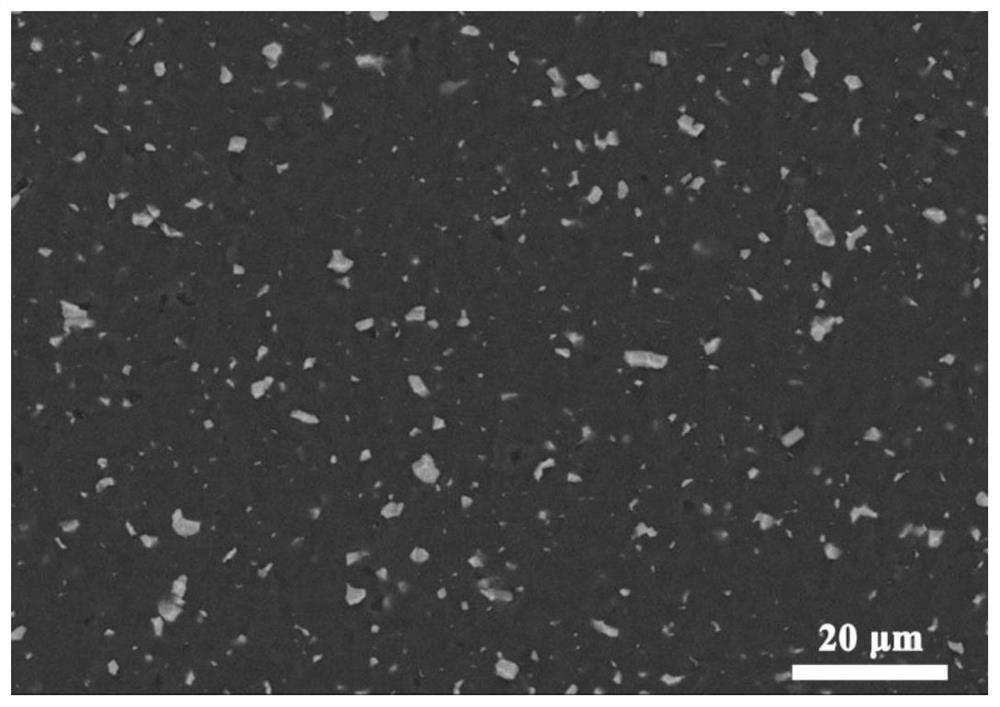

[0031] Example 1, see figure 1 :

[0032] The invention provides a boron carbide-titanium boride lightweight high-strength composite ceramic material and a preparation method thereof, which is prepared from the following components and their mass percentages: boron carbide powder 82.05%, titanium carbide powder 8.20%, amorphous boron powder 9.75%, its preparation method comprises the steps:

[0033] 1) take titanium carbide powder and amorphous boron powder by proportioning;

[0034] 2) The weighed titanium carbide powder and amorphous boron powder are mixed into a slurry by a drum mixer; the mixed slurry is subjected to rotary evaporation, then placed in a vacuum drying oven to dry, and TiC is obtained after sieving -B mixed powder;

[0035] 3) Put the TiC-B mixed powder in a hot-pressed sintering furnace, and obtain the synthesized primary B after heat treatment in the hot-pressed furnace 4 C-TiB 2 Composite powder;

[0036] 4) Weigh primary B according to the ratio 4...

Embodiment 2

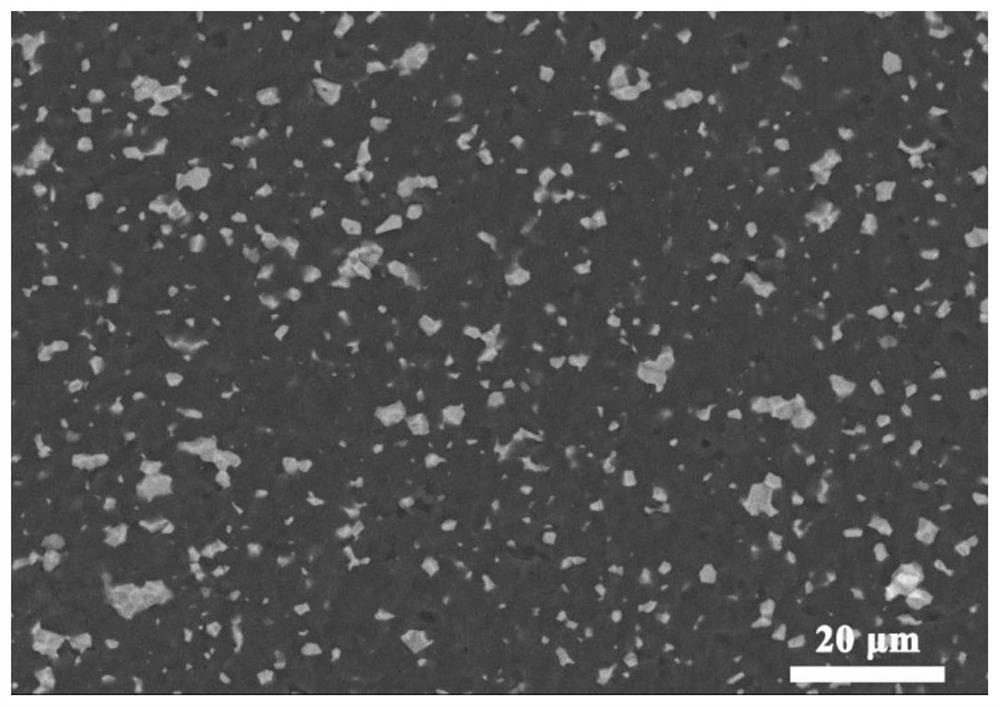

[0040] Example 2, see figure 2 :

[0041] The present invention provides a boron carbide-titanium boride lightweight high-strength composite ceramic material and a preparation method thereof, which are basically the same as in Example 1, except that it is prepared from the following components and their mass percentages: boron carbide powder 64.10% , titanium carbide powder 16.40%, amorphous boron powder 19.50% (see the SEM image of the sample figure 2 ).

Embodiment 3

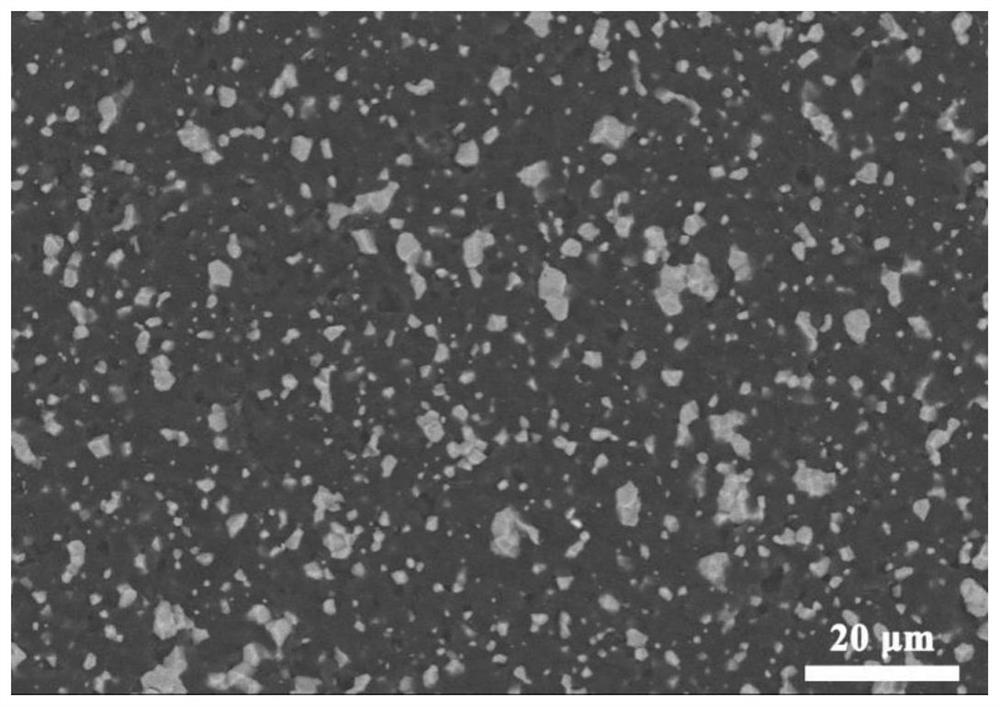

[0042] Example 3, see image 3 :

[0043] The present invention provides a boron carbide-titanium boride lightweight high-strength composite ceramic material and a preparation method thereof, which are basically the same as in Example 1, except that it is prepared from the following components and their mass percentages: boron carbide powder 46.15% , titanium carbide powder 24.55%, amorphous boron powder 29.30% (see the SEM image of the sample image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com