Preparation method of high-strength spherical agglomerated boron particles

A high-strength, spherical technology, applied in the direction of explosives, etc., can solve the problems of difficult ignition of secondary combustion, large particle size of boron powder, full combustion, etc., and achieve the effect of increased density, controllable particle size, and unbreakable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In a planetary vertical kneader, 8.5 g of polyurethane prepolymer binder hydroxyl-terminated polybutadiene (HTPB, E OH =7.8×10 -4 mol / g) was dissolved in 170ml of ethyl acetate, and 0.6g of 1,4-toluene diisocyanate curing agent (TDI) was added to premix evenly (control the temperature of the material at 30±5°C), and then 85g of boron powder was added to the above premixed material Mix well, and finally dissolve 0.03g dibutyltin dilaurate (T-12) in 0.5g ethyl acetate, add to the above mixture and mix thoroughly; pass the obtained granular materials through 60 mesh to 80 mesh and a 100-140-mesh standard sieve, and vacuum-dry at 50°C for 72 hours.

[0026] Performance Testing

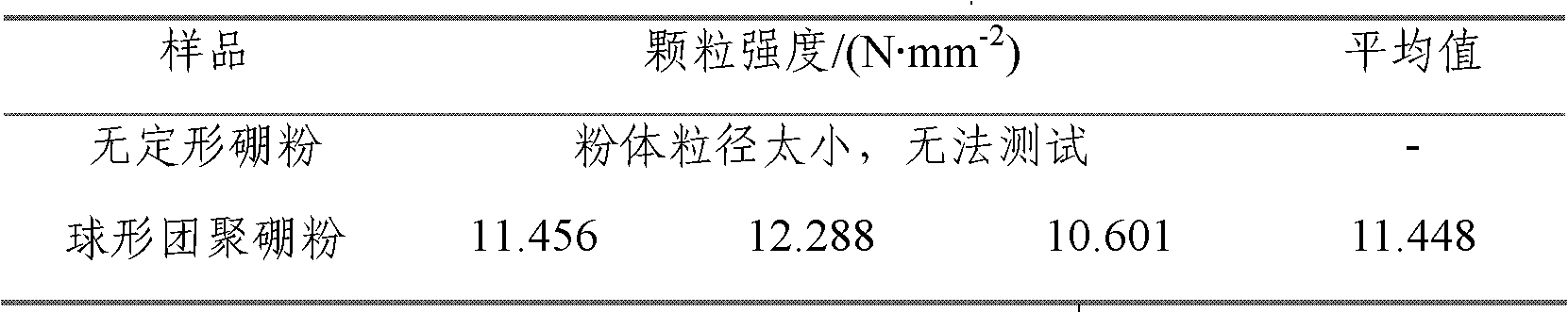

[0027] 1. Particle strength test

[0028] The testing instrument is ZQJ-II intelligent particle strength testing machine.

[0029] Test method: The agglomerated boron particles are sieved by a standard sampling sieve, and classified according to the particle size. In order to make the experiment...

Embodiment 2

[0051]2g of surface modifier TMP was dissolved in 200ml of acetone, 98g of amorphous boron powder was added, stirred and reacted at 50°C for 24h, and the solvent was removed by vacuum drying at 70°C to obtain surface-modified boron powder. In a planetary vertical kneader, 8.5g of polyurethane prepolymer binder hydroxyl-terminated polybutadiene (HTPB, hydroxyl value: 7.8×10 -4 mol / g) was dissolved in 170ml of ethyl acetate, and 5g of ammonium perchlorate and 0.6g of 1,4-toluene diisocyanate curing agent (TDI) were added to premix evenly, and the temperature of the material was controlled at 30±5°C; 85g of surface modified Add boron powder to the above premixed material and mix thoroughly; dissolve 0.03g of dibutyltin dilaurate (T-12) in 0.5g of ethyl acetate, add to the above mixed material and mix thoroughly; pass the obtained granular material 60 mesh to 80 mesh and 100 mesh to 140 mesh standard sieve, vacuum dried at 50°C for 72 hours.

[0052] Performance Testing

[0053]...

Embodiment 3

[0059] The implementation method of this example is basically the same as that of Example 2, except that the adhesive prepolymer uses carboxyl-terminated polybutadiene, and the amount is 9.0g, the curing agent is HDI, and the amount is 1.05g, and the amount of ammonium perchlorate is 7.0 g.

[0060] Performance Testing

[0061] The test apparatus and test method are the same as in Example 1, and the results are shown in Table 7 and Table 8 below.

[0062] Particle strength of table 7 agglomerated boron powder

[0063]

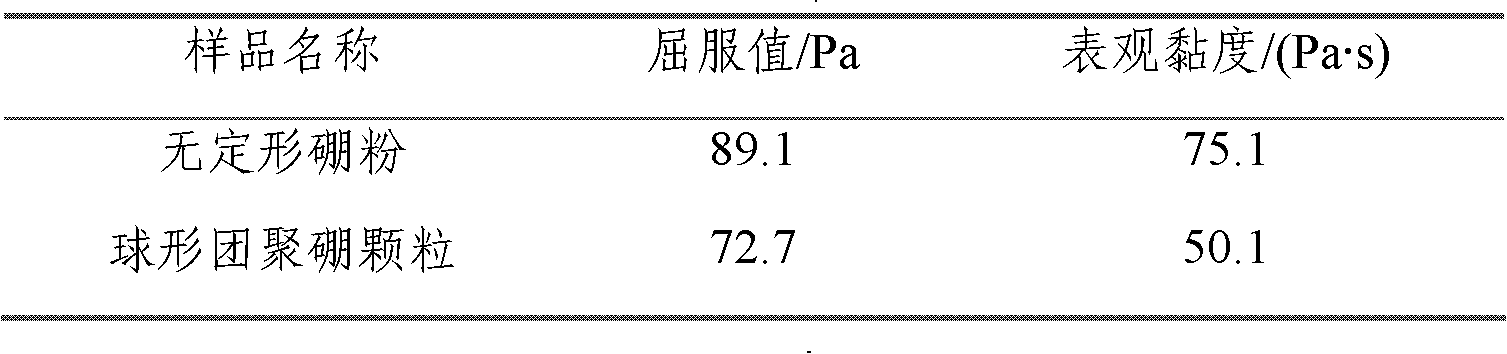

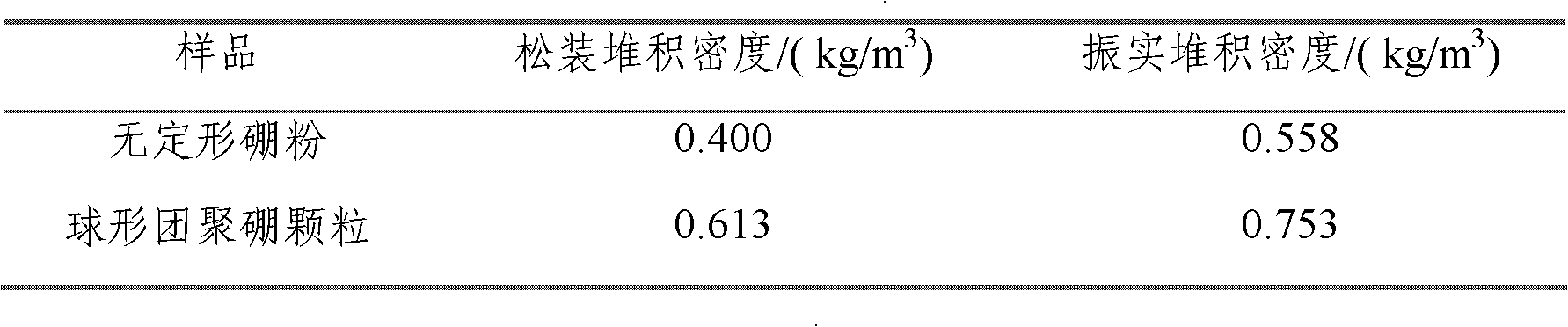

[0064] Table 8 Boron powder density results and rheological properties of B / HTPB suspension

[0065]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com